Pure cotton fabric with good stability

A stability and fabric technology, applied in the textile field of pure cotton fabrics, can solve the problems of poor pull resistance, poor stability and durability, etc., and achieve the effect of improving strength, stability and durability, and improving pull resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

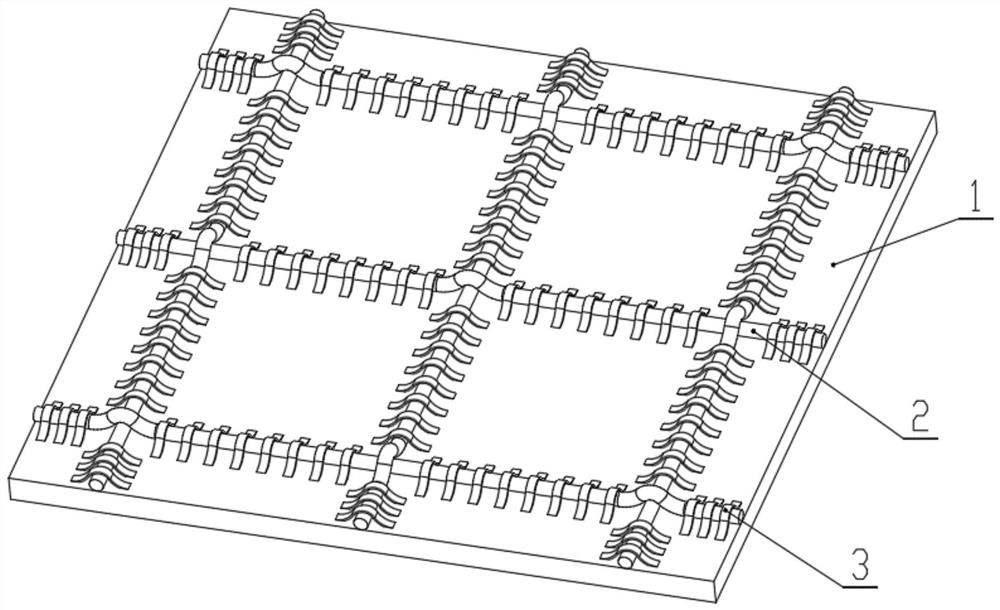

[0022] During the weaving process of the fabric main body 1, the reinforced cotton thread 2 is evenly placed on the surface of the fabric main body 1 in a criss-cross pattern;

[0023] The staggering directions of every two adjacent transverse reinforcing cotton threads 2 and vertical reinforcing cotton threads 2 are opposite;

[0024] Use the fixed thread 3 to surround the outer side of the reinforced cotton thread 2, embed the lower end of the fixed thread 3 into the interior of the fabric main body 1, so that the lower end of the fixed thread 3 and the fabric main body 1 are woven together;

[0025] And the fixed thread 3 is evenly covered with the outer side of the reinforced cotton thread 2, and the reinforced cotton thread 2 and the fabric main body 1 are woven into one through the fixed thread 3;

[0026] At the same time, the outer surface of the fabric main body 1 forms a grid-shaped raised pattern;

[0027] After the weaving is completed, the singeing process is per...

Embodiment 2

[0035] Place reinforced cotton threads 2 evenly in a criss-cross pattern on the surface of the woven fabric main body 1;

[0036] The staggering directions of every two adjacent transverse reinforcing cotton threads 2 and vertical reinforcing cotton threads 2 are opposite;

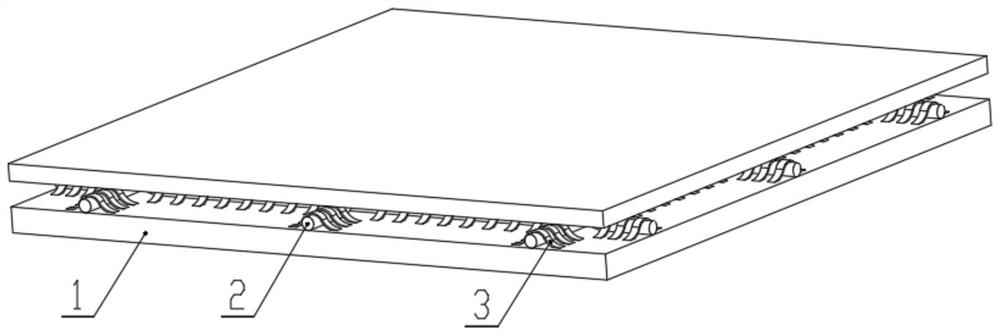

[0037] Place another layer of fabric main body 1 on the upper side of the reinforced cotton thread 2, and then use the fixed thread 3 to weave the two layers of fabric main body 1 into one, and at the same time limit the position of the reinforced cotton thread 2 through the fixed thread 3;

[0038] After the weaving is completed, the singeing process is performed, the gas singeing machine is started, and the fluff on the surface of the textile is burned by the flame or the heat radiation generated when the combustible gas is burned;

[0039] Use the principle of different heating rates between the cloth body and the fluff to burn off the fine fluff on the surface of the cloth while ensuring the safety of ...

Embodiment 3

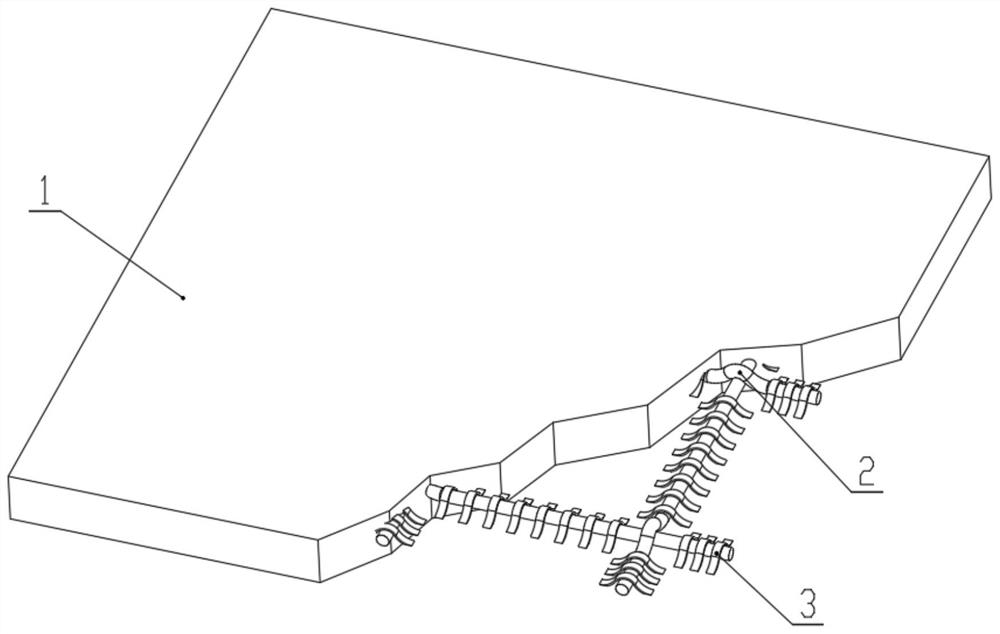

[0046] During the weaving process of the fabric main body 1, the reinforced cotton thread 2 is evenly placed inside the fabric main body 1 in a criss-cross pattern;

[0047] The staggering directions of every two adjacent transverse reinforcing cotton threads 2 and vertical reinforcing cotton threads 2 are opposite;

[0048] Make the fabric main body 1 and the reinforcing cotton thread 2 form a whole during the weaving process;

[0049] After the weaving is completed, the singeing process is performed, the gas singeing machine is started, and the fluff on the surface of the textile is burned by the flame or the heat radiation generated when the combustible gas is burned;

[0050] Use the principle of different heating rates between the cloth body and the fluff to burn off the fine fluff on the surface of the cloth while ensuring the safety of the cloth itself;

[0051] After the singeing is completed, the desizing process is carried out, and the pure cotton fabric is soaked i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com