Kinematic pair joint gap eliminating mechanism for feeding robot and implementation method of kinematic pair joint clearance eliminating mechanism

A joint gap and robot technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of simultaneous elimination, general use effect, and affecting the normal operation of equipment, so as to improve stability and durability and eliminate kinematic joints gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0033]The implementation method of the kinematic pair joint gap elimination mechanism of the feeding robot includes the following steps:

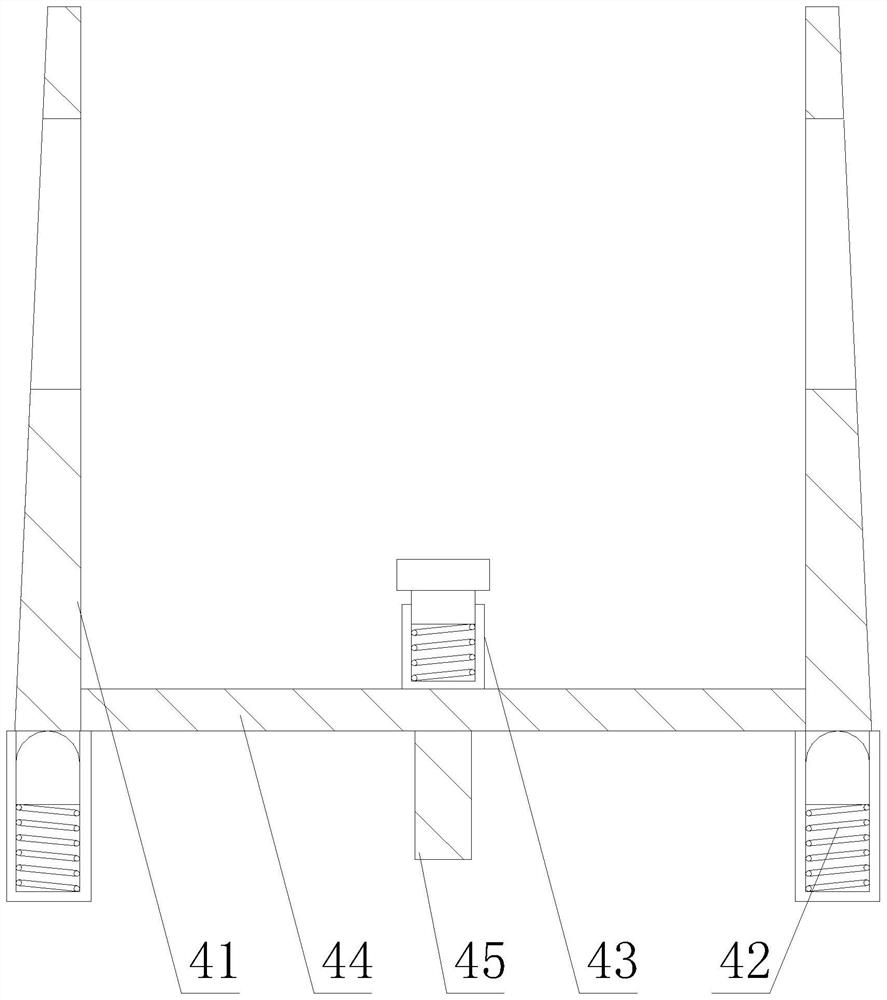

[0034] The first step: first install the first compensation structure 42 in the compensation assembly 4 at a predetermined position in the inner cavity of the base arm 3, wherein the first compensation structure 42 is symmetrically installed in the inner cavity of the base arm 3;

[0035] Step 2: install the remaining parts in the compensation assembly 4 in the inner cavity of the base arm 3, wherein it is necessary to ensure that the bottom surface of the compensation plate 41 is in contact with the first compensation structure 42, and after the entire compensation assembly 4 is installed, it must be ensured that it will not Affect the normal operation of the swing arm 1, the transverse circular shaft 2 and the base arm 3;

[0036] Step 3: Then install the swing arm 1 to the predetermined position, wherein the swing arm 1 needs to be froze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com