3D printer leveling device

A 3D printer and leveling device technology, which is applied to manufacturing auxiliary devices, 3D object support structures, processing platforms/substrates, etc. The effect of adjusting and leveling the forming platform is convenient and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

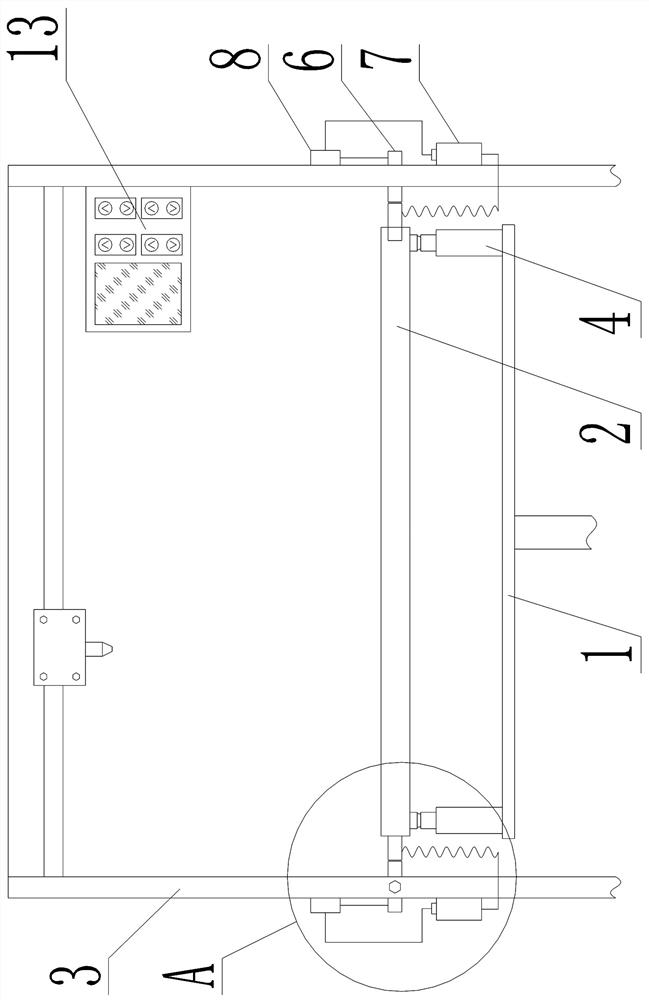

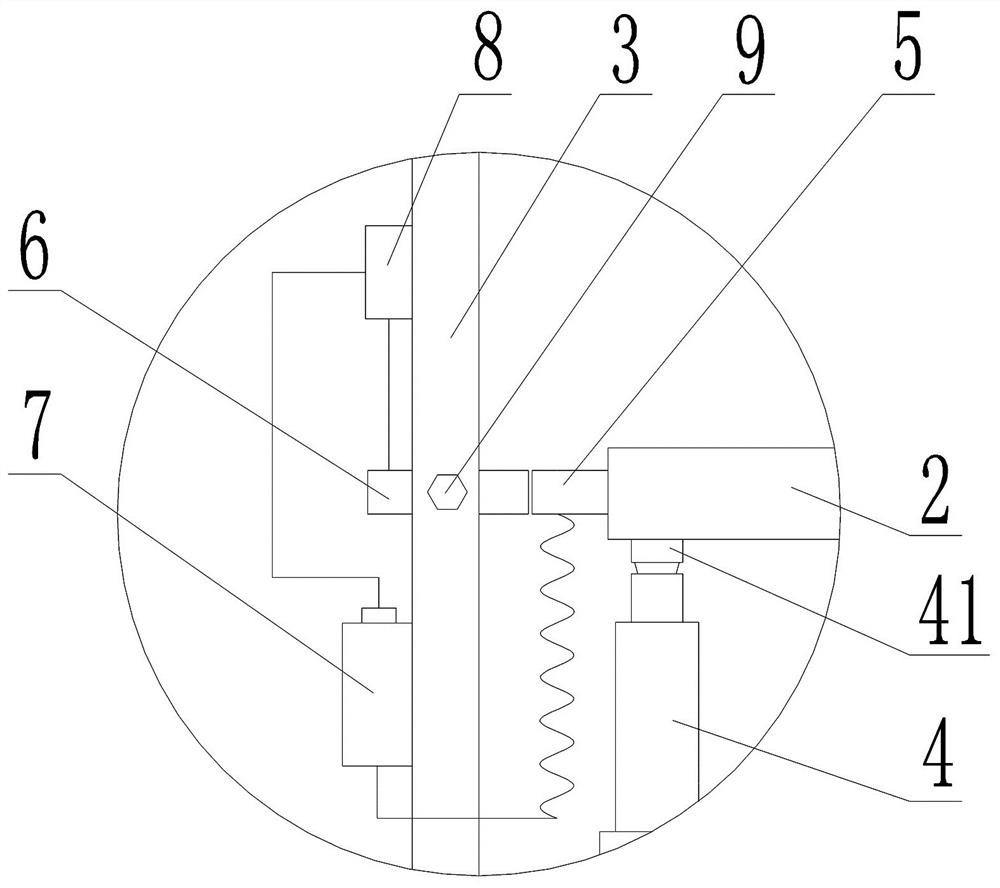

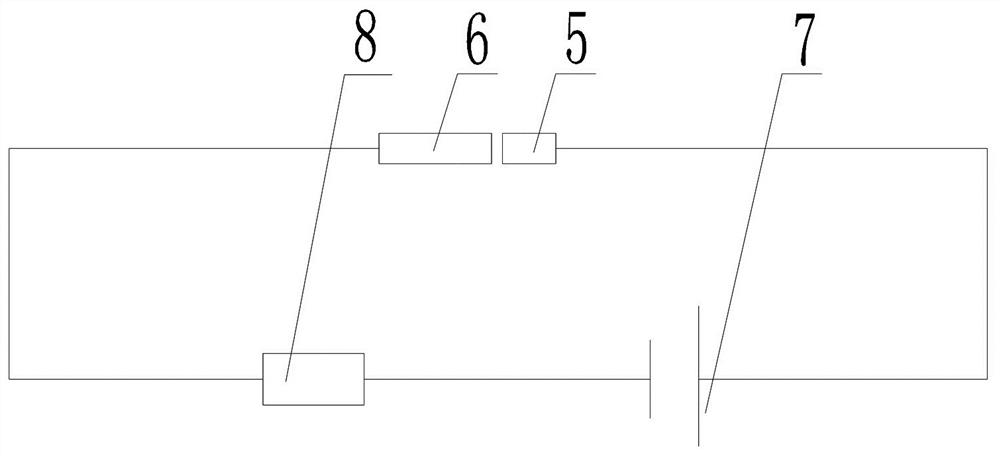

[0035] A 3D printer leveling device, please refer to figure 1 and figure 2 , including a fixed platform 1, a forming platform 2 and a frame 3, the fixed platform 1 is located below the forming platform 2, the forming platform 2 is a rectangular structure, and also includes a linear stepping motor 4, a first metal block 5, and a second metal block 6 , DC power supply 7, alarm 8 and observation window.

[0036] Wherein, there are four linear stepping motors 4, all of which are arranged on the fixed platform 1, and the piston rods of each linear stepping motor 4 are all vertically arranged, and the upper ends of the four linear stepping motors 4 piston rods are respectively connected with a spherical surface. The secondary connectors 41 , the four spherical secondary connectors 41 are respectively connected to the four corners of the forming platform 2 .

[0037] see Figure 4 , There are four first metal blocks 5, which are respectively arranged at the four corners of the fo...

Embodiment 2

[0047] A 3D printer leveling device, please refer to Figure 6 and Figure 7 , including a fixed platform 1, a forming platform 2 and a frame 3, the fixed platform 1 is located below the forming platform 2, the forming platform 2 is a rectangular structure, and also includes a linear stepping motor 4, a first metal block 5, and a second metal block 6 , DC power supply 7, alarm 8 and observation window.

[0048] Wherein, there are four linear stepping motors 4, all of which are arranged on the fixed platform 1, and the piston rods of each linear stepping motor 4 are all vertically arranged, and the upper ends of the four linear stepping motors 4 piston rods are respectively connected with a spherical surface. The secondary connectors 41 , the four spherical secondary connectors 41 are respectively connected to the four corners of the forming platform 2 .

[0049] see Figure 4 , There are four first metal blocks 5, which are respectively arranged at the four corners of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com