Mold for injection molding of plastic water cup

A water cup and mold technology, applied in the field of production and manufacturing, can solve problems affecting product quality, large floor space, surface scratches, etc., and achieve the effect of prolonging the injection molding time, ensuring the effect, and avoiding the incomplete cup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

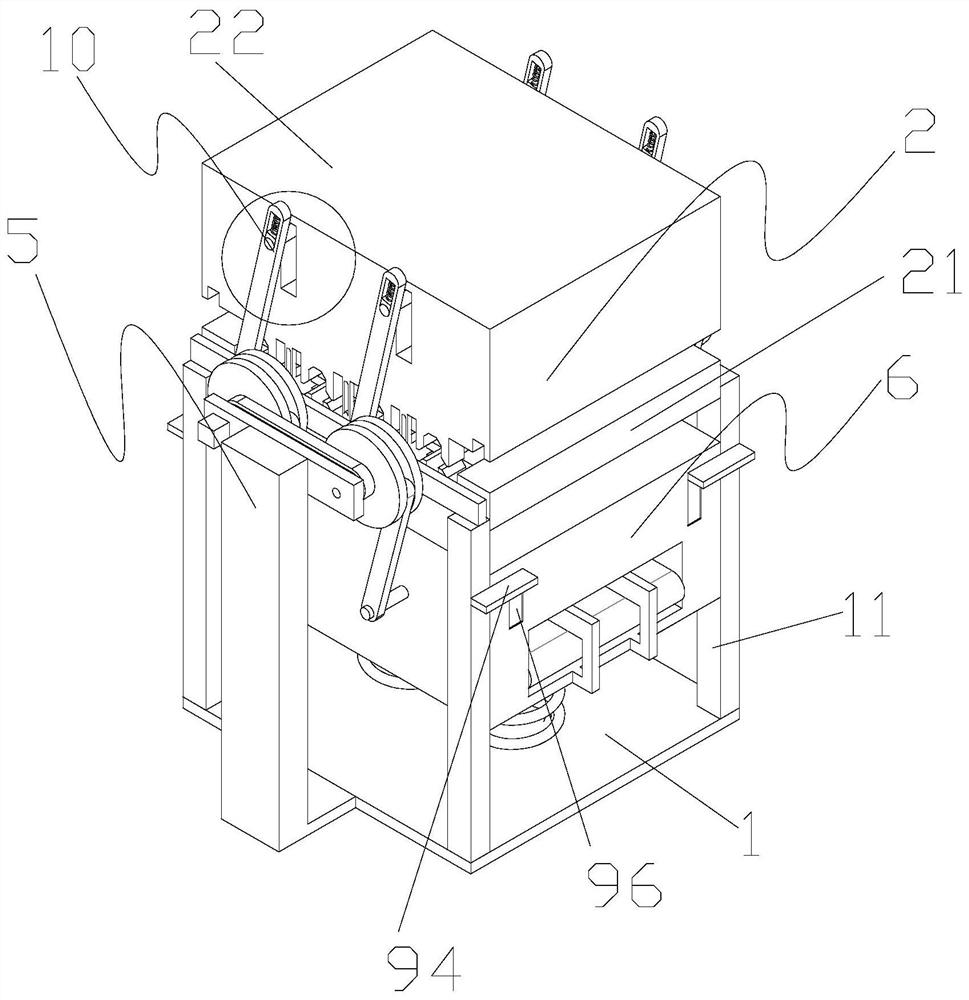

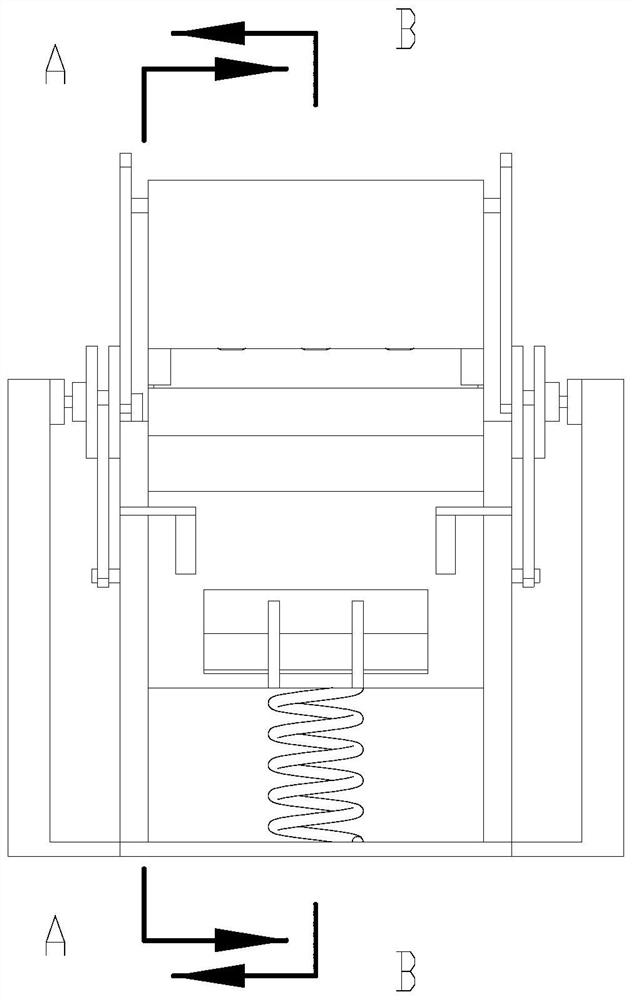

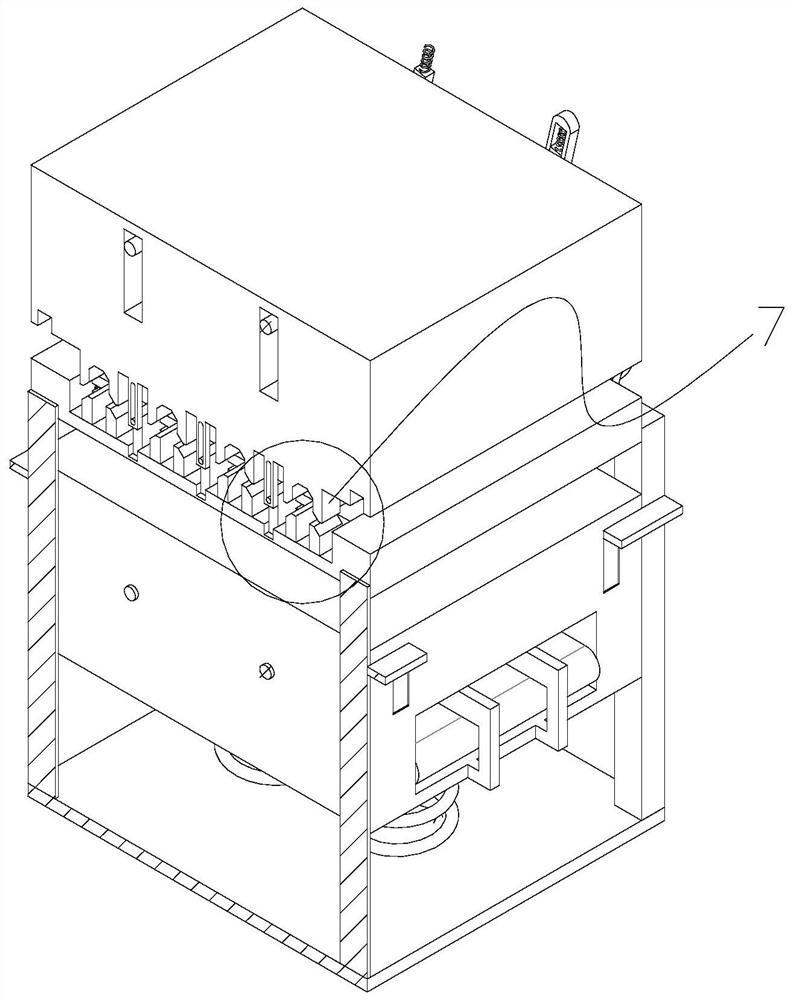

[0029] Such as Figure 1-15 As shown, a plastic water cup injection molding mold includes a base plate 1, a column 11, and a water cup injection device 2; the column 11 is erected on the base plate 1, and the water cup injection device 2 is located on the column 11; Module 21, upper module 22, cylinder 23, limit block 24, limit groove 25, split cavity 3, injection molding core 4, transmission structure 5, material receiving structure 6; the lower module 21 is fixedly connected to the column 11, The upper module 22 is arranged above the lower template, and a plurality of cylinders 23 are arranged on both sides of the lower module 21. The limiting block 24 is arranged below the upper module 22, and the limiting groove 25 is opened in the limiting block. 24, the split-type cavity 3 is set on the lower module 21, the injection molding core 4 is set on the upper module 22, the transmission structure 5 is used to drive the upper module 22 to move up and down, and the material receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com