Table Saw Fence With Adjustment Mechanism

A fence and angle adjustment technology, used in manufacturing tools, sawing machines, sawing components, etc., can solve the problem of difficulty in adjusting the position of the fence, and achieve the effect of straight cutting and reproducible cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

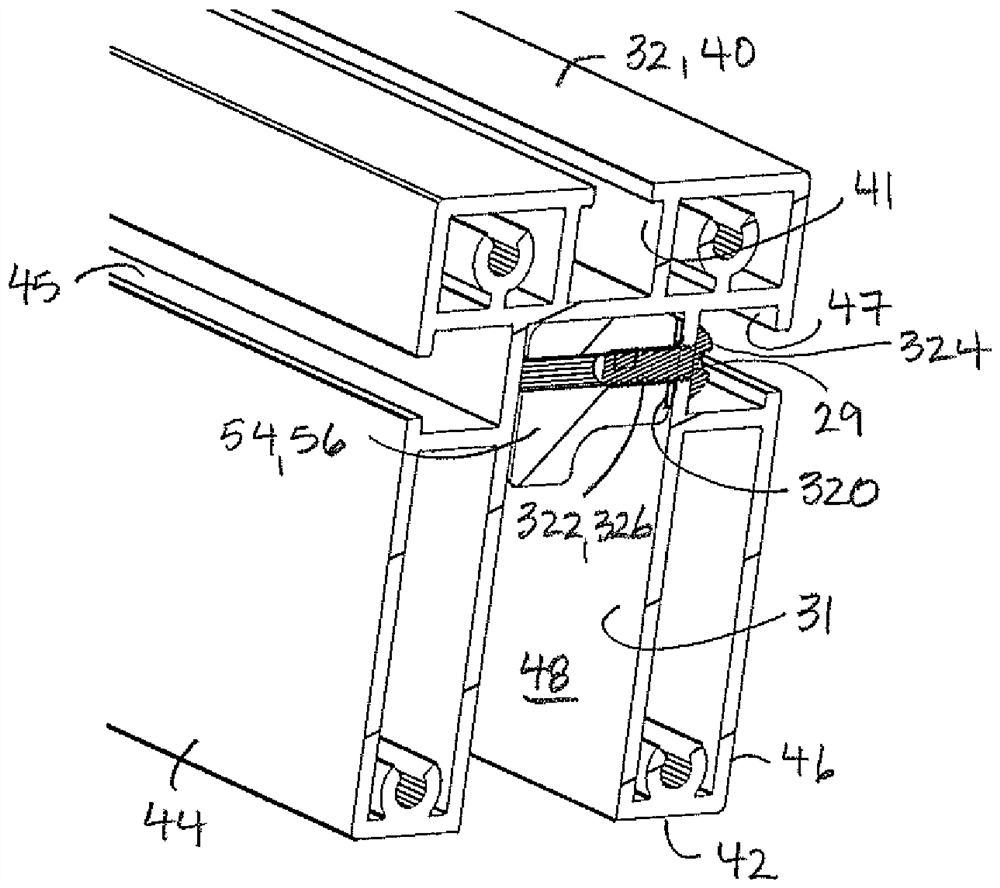

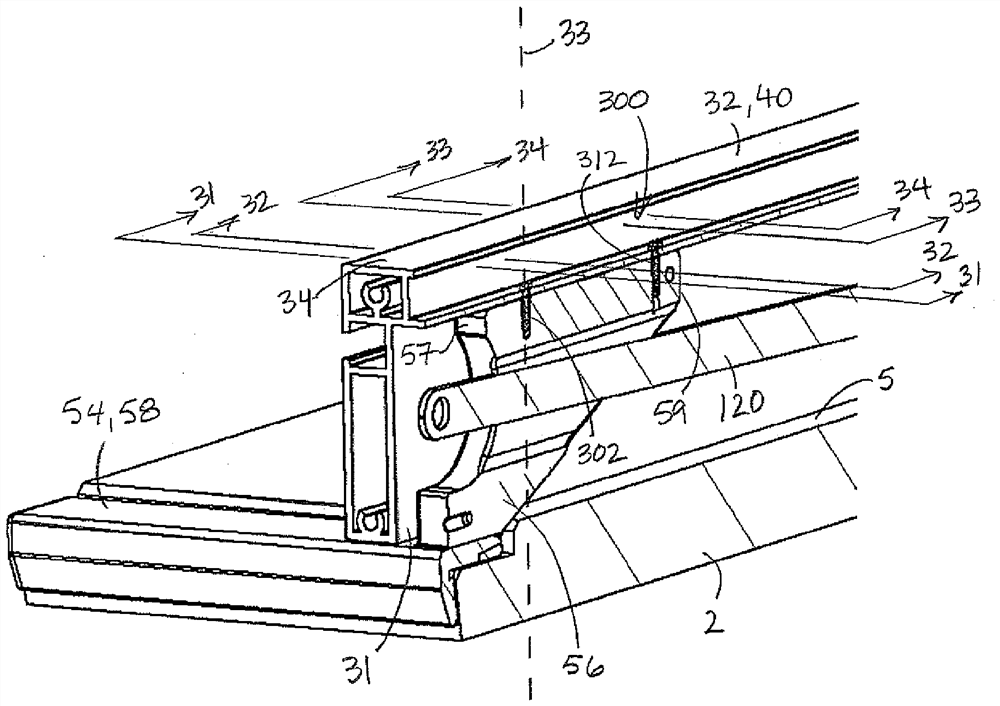

[0061] refer to Figure 1 to Figure 7 , the saw device 1 comprises a table top 2 and a fence assembly 30 supported on the saw device 1 such that the fence 32 overlies the table top 2 and extends parallel to the cutting blade 8 of the saw device 1 . The saw device 1 illustrated in the figures is, for example, a table saw, although in other embodiments the saw device 1 may be configured as another type of cutting tool, wherein the fence assembly is used to place the workpiece (not shown) relative to the blade 8. shown) positioned on the surface. The saw table top 2 is part of a saw table or cabinet structure (not shown) and defines a flat work surface 5 for supporting a workpiece. The table top 2 includes an opening 6 . A blade 8 of the saw device 1 , eg a circular saw blade, protrudes through the opening 6 and an insert 9 is disposed in the opening 6 between the blade and the working surface 5 . A motor (not shown) is housed inside the cabinet of the saw device 1 and is conf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com