Manufacturing method of oversized wax mould

A technology with super large size and manufacturing method, which is applied in the field of investment casting, can solve the problems of difficult surface quality assurance, difficult wax mold stamping, and inability to press wax molds, so as to improve market competitiveness, good consistency, and wax molds. good size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for manufacturing an oversized wax model, comprising the steps of:

[0029] S1. Divide the wax mold into equal parts: Divide into equal parts according to the overall structure 1 of the wax mold, so that each part of the wax mold has the same structure and shape, and manufacture a single wax mold 2;

[0030] S2. Wax mold correction: place the manufactured single wax mold 2 into the correction mold, and precisely correct the single wax mold 2;

[0031] S3. Wax mold assembly: put the rectified single wax mold 2 close to each other in the assembly tool and press and fix it;

[0032] S4. Wax mold repair: bonding and repairing the gaps between adjacent single wax molds, and removing the whole wax mold after the bonding seam is finalized to obtain a super-sized wax mold of the required size.

Embodiment 2

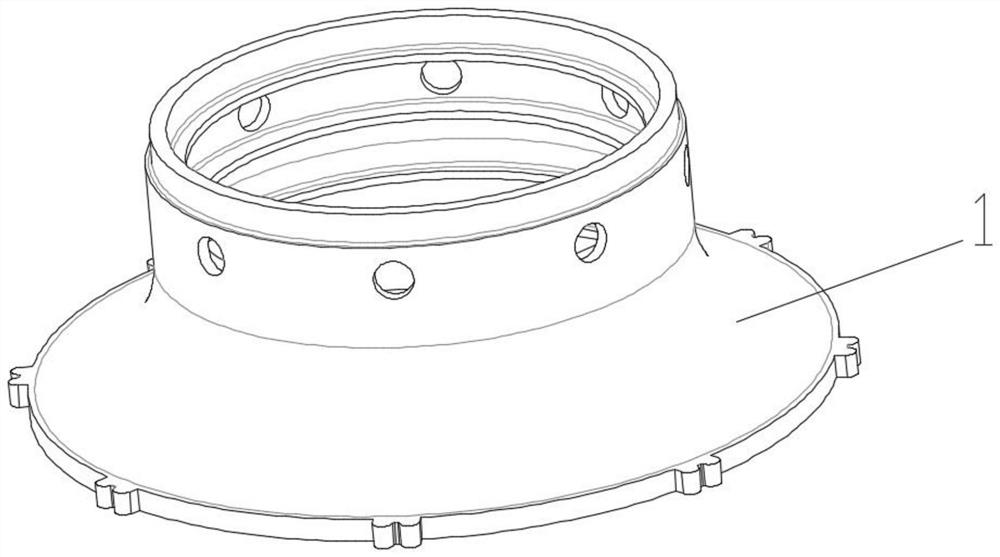

[0034] as figure 1 The overall structure 1 of the annular wax model shown is taken as an example,

[0035] The overall structure of the wax model 1 has a size of 1259.35*1259.35*435mm, which is a super-large ring wax model.

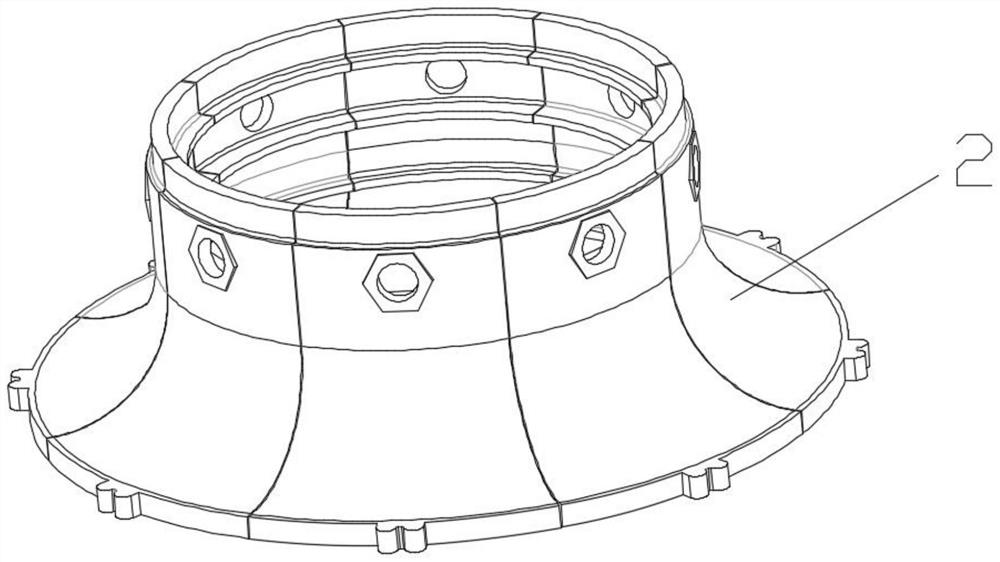

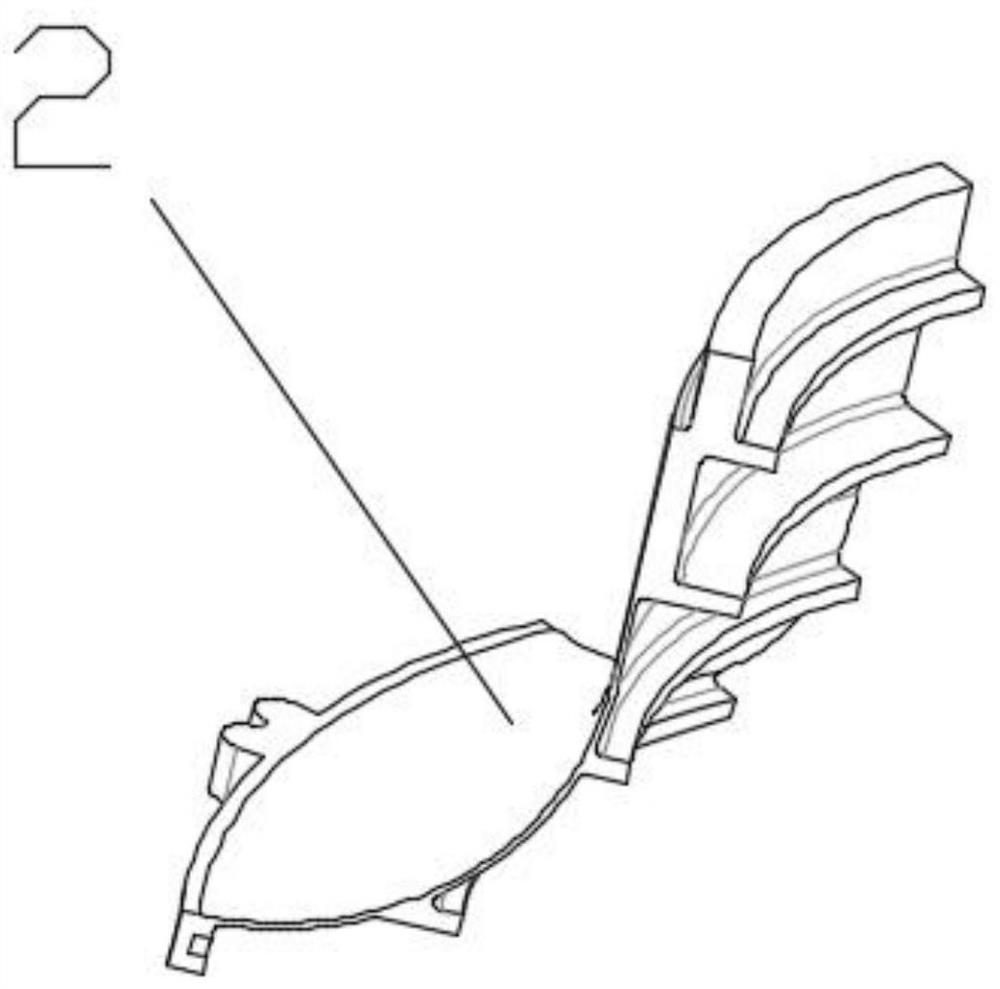

[0036] like Figure 2-3 As shown, according to the overall structure 1 of the wax mold, it is divided into several single wax molds 2. In this embodiment, it is divided into 8 pieces to ensure that each piece has the same size and structure. Dimensions are prepared to correct the mold. The corrected mold includes a shaping bottom mold 3 for placing a single wax mold 2 and a straightening pressure mold 4 for sealing and shaping the wax mold. Between the straightening pressure mold 4 and the shaping bottom mold 3 The formed hollow body is consistent with the standard size of the monolithic wax mold 2;

[0037] like Figure 4-5 As shown, after the preparation of the monolithic wax mold 2 is completed, the monolithic wax mold 2 is placed on the shaped bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com