Construction steel bar cutoff device

A cutting device and a technology for building steel bars, which are applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient steel bar measurement, low safety and practicability, and easy to cause danger, so as to improve the safety of use, the use of High convenience and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

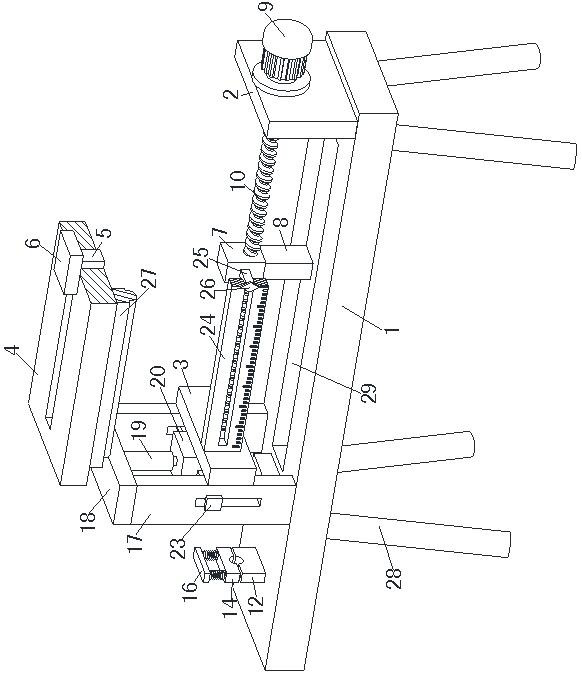

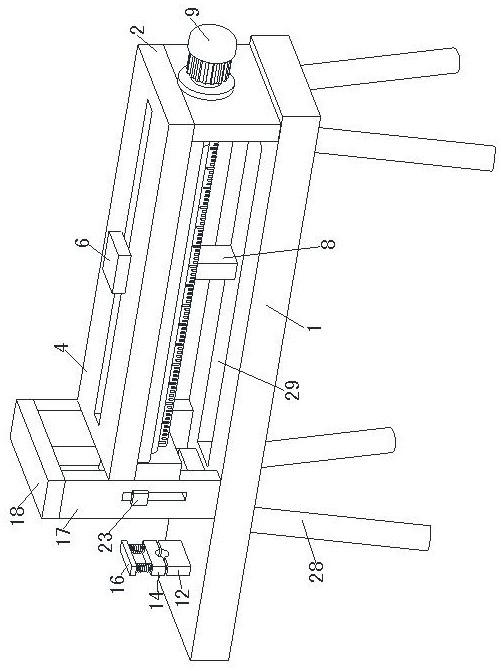

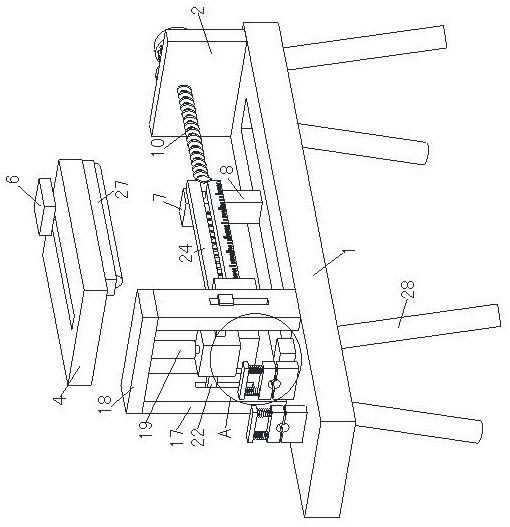

[0024] see Figure 1-5 , a construction reinforcement cutting device, including a working plate 1, and also includes a measuring mechanism and a clamping mechanism, the measuring mechanism includes a first fixed plate 2 and a second fixed plate 3, the bottom end of the first fixed plate 2 is fixed to the working plate 1 Connection, the top of the first fixed plate 2 and the second fixed plate 3 are fixedly connected with the top plate 4, the bottom of the top plate 4 is equipped with a lighting tube 27, and the measuring plate 24 is illuminated by the lighting tube 27, which is convenient for the user to observe and measure The scale on the plate 24 improves the convenience of use. The top plate 4 is provided with a first chute, the inside of the first chute is slidably connected with a slider 5, and the top of the slider 5 is fixedly connected with a first stopper 6. The bottom end of block 5 is fixedly connected with baffle plate 8 by mounting plate 7, is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com