Blasting bead and preparation method thereof

A technology of popping beads and core material, which is applied in the field of popping beads and its preparation, which can solve the problems of single popping bead shape, high permeability, and limited use of popping beads, so as to improve the fun, improve the barrier performance, and enhance the stimulation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

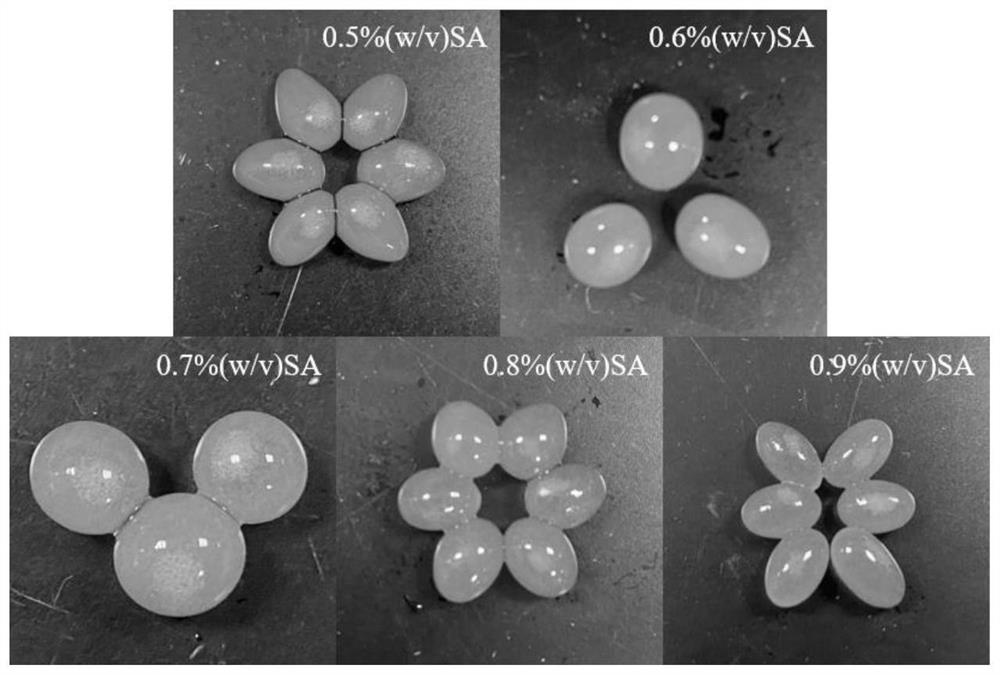

[0036] Preparation of coagulation bath solution: Dissolve 1g of sodium alginate (SA) in 99g of deionized water to obtain a 1wt% sodium alginate solution, and dissolve 70mL of 1wt% sodium alginate solution in 30mL of deionized water to obtain 0.7wt% of Sodium alginate solution.

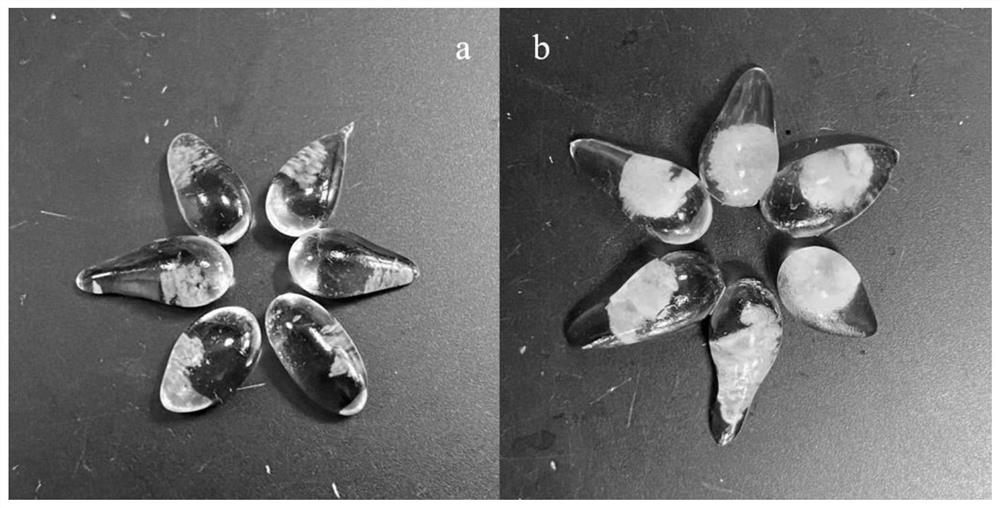

[0037] Preparation of core material solution: Mix 1 g of zein with deionized water, adjust the pH with 1 mol / L NaOH, and finally obtain 100 mL of 0.01 kg / L zein solution with pH=12. Dissolve 0.1 g of brilliant blue / erythrosine powder in 20 mL of deionized water to prepare a 0.0050 kg / L brilliant blue / erythrosine solution. Add 1 mL of 0.0050 kg / L brilliant blue solution / erythrosine solution to the above zein solution at pH=12 to obtain a zein solution containing 0.000050 kg / L brilliant blue / erythrosine. Take 25 mL of zein solution containing 0.000050 kg / L brilliant blue / erythrosine, add 0.625 g of carboxymethyl cellulose (CMC) under magnetic stirring, and after fully dissolving, add 1 mol / L HCl dropwis...

Embodiment 2

[0040] Preparation of coagulation bath solution: 1 g of sodium alginate (SA) was dissolved in 99 g of deionized water to obtain a 1 wt % sodium alginate solution. 70 mL of 1 wt % sodium alginate solution was dissolved in 30 mL of deionized water to obtain a 0.7 wt % sodium alginate solution.

[0041]Preparation of core material solution: Mix 1 g of zein with deionized water, adjust the pH with 1 mol / L NaOH, and finally obtain 100 mL of 0.01 kg / L zein solution with pH=12. Dissolve 0.1 g of brilliant blue / erythrosine powder in 20 g of deionized water to prepare a 0.0050 kg / L brilliant blue / erythrosine solution. Take 50 mL of zein solution with pH=12, add 0.5 mL of 0.0050 kg / L brilliant blue solution / erythrosine solution to obtain a zein solution containing 0.000050 kg / L brilliant blue / erythrosine. Take 25mL of zein solution containing 0.000050kg / L Brilliant Blue / Erythrosin, add 1mol / L HCl dropwise to pH=5 under magnetic stirring, consume 0.5mL of HCl solution, add 0.625g of CMC...

Embodiment 3

[0046] Preparation of coagulation bath solution: 1 g of sodium alginate (SA) was dissolved in 99 g of deionized water to obtain a 1 wt % sodium alginate solution. 70 mL of 1 wt % sodium alginate solution was dissolved in 30 mL of deionized water to obtain a 0.7 wt % sodium alginate solution.

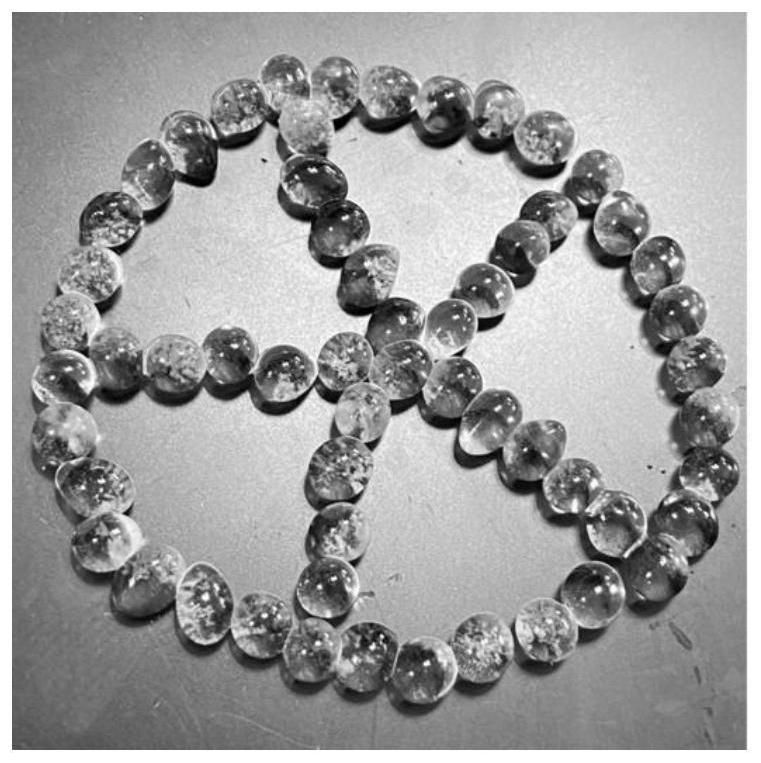

[0047] Preparation of core material liquid: Take 0.2, 0.4, 0.8, 1g of zein and mix them with deionized water, adjust the pH with 1mol / L NaOH, and finally get 0.002, 0.004, 0.008, 0.01kg / L of zein solution. Dissolve 0.1 g of brilliant blue / erythrosine powder in 20 g of deionized water to prepare a 0.0050 kg / L brilliant blue / erythrosine solution. Add 1 mL of 0.0050 kg / L brilliant blue solution / erythrosine solution to the above zein solution at pH=12 to obtain a zein solution containing 0.000050 kg / L brilliant blue / erythrosine. Take 25mL of zein solution containing 0.000050kg / L Brilliant Blue / Erythrosin, respectively, add 0.5g of CMC under magnetic stirring, after mixing evenly, add 1mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com