Gas-insulated totally-enclosed electrical equipment

A technology of electrical equipment and gas insulation, which is applied in the direction of electrical components, switchgear settings, switchgear, etc., and can solve the problems of temperature rise, flow capacity and insulation performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

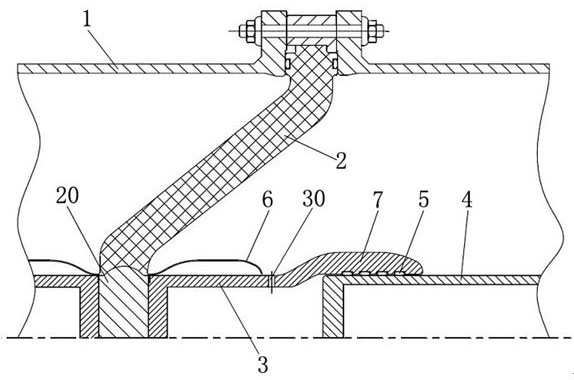

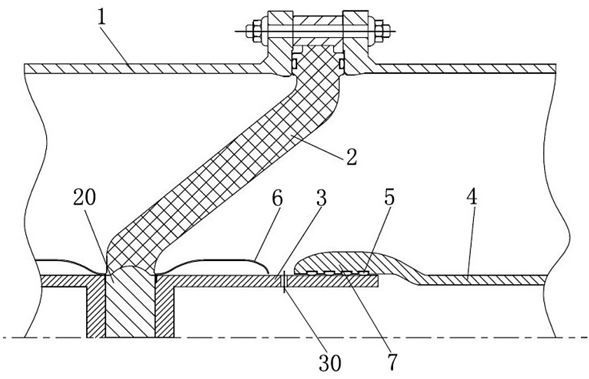

[0029] This embodiment takes GIL as an example for illustration, of course, in other embodiments, the gas-insulated fully enclosed electrical equipment may also be GIS.

[0030] specific reference figure 1 , the gas-insulated fully-enclosed electrical equipment of this embodiment includes a closed casing, and the closed casing includes a plurality of sealing cylinders 1, and a basin-type insulator 2 is sandwiched between two adjacent sealing cylinders 1, and the basin-type insulator 2 includes The insulating basin and the metal insert 20 embedded in the basin bottom of the insulating basin, the two sides of the metal insert 20 are respectively fixedly connected with the conductive seat 3, and the two conductive seats 3 are respectively arranged in the corresponding sealing cylinder 1 Conductor 4 for plug-in connection. This embodiment is an introduction to the structure and connection method of the conductive seat 3 and the conductor 4 on the side of the pot mouth of the pot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com