Multilayer transparent conductive anti-reflection film LED chip

A technology of LED chips and anti-reflection films, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as reduced work efficiency, impact on normal use, and inconvenience to users, and achieve the effect of improving work efficiency and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

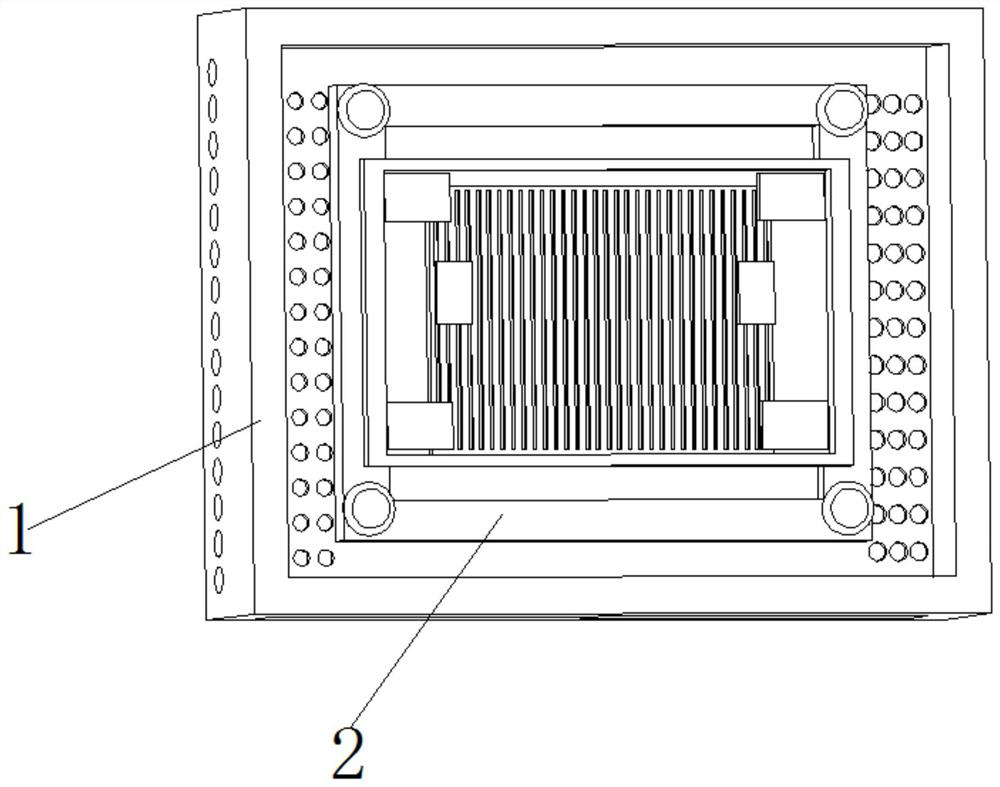

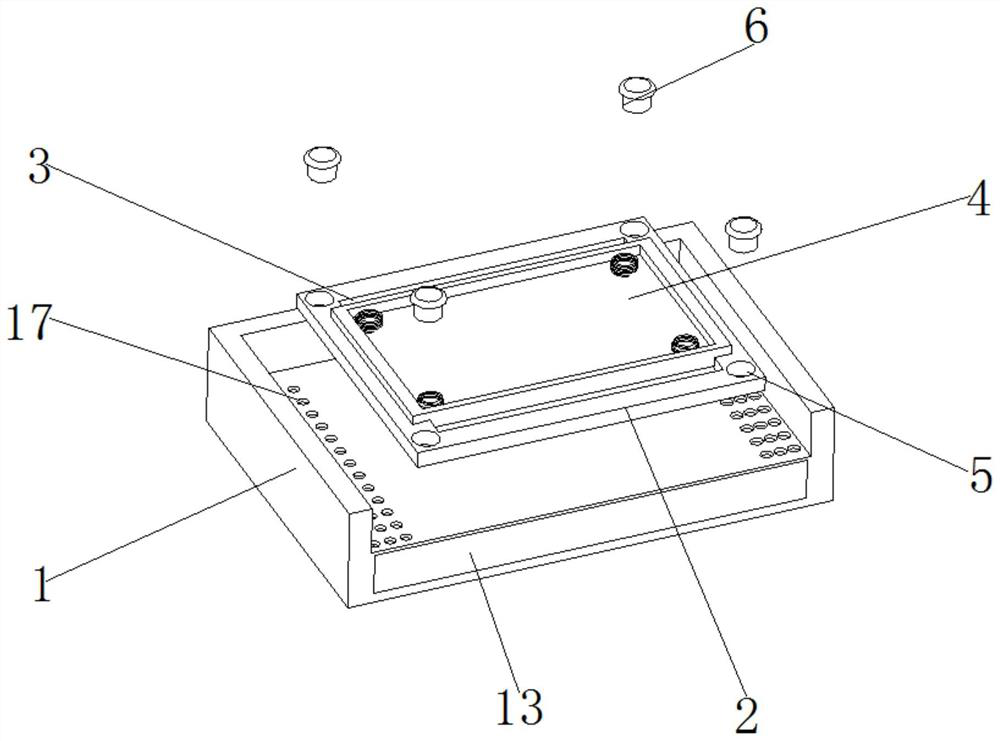

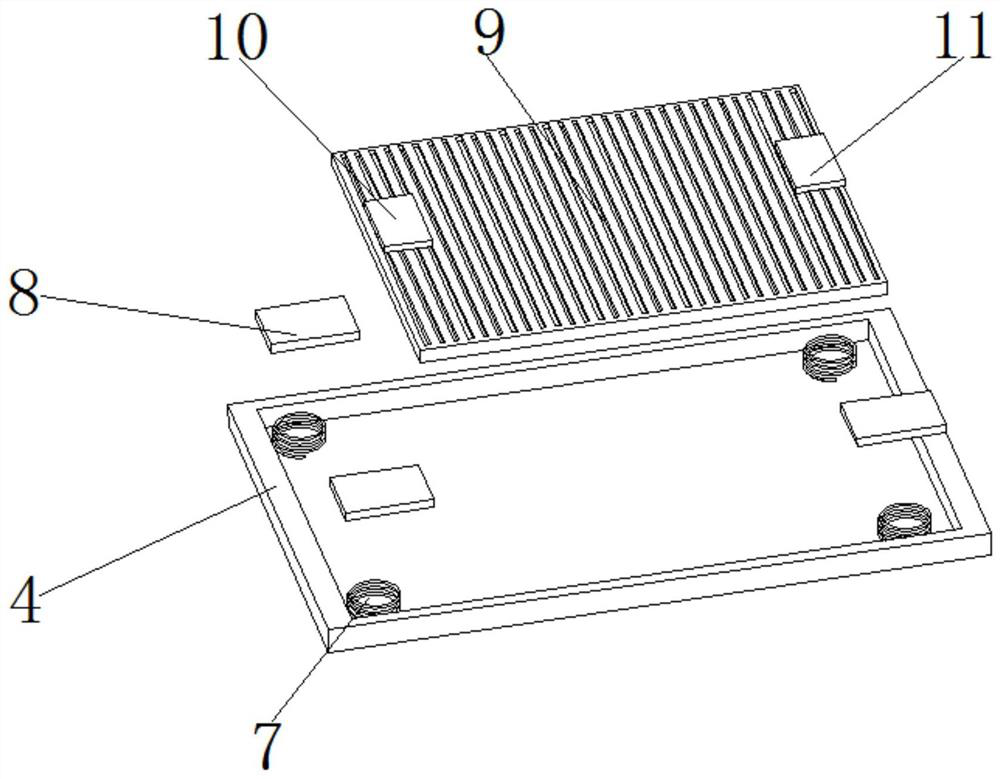

[0030] See Figure 1-5 A multi-layer transparent conductive, an increased film LED chip, including a casing 1, a metal seat 2 in the inside of the casing 1, and a card slot 3 is opened in both sides of the metal seat 2, each card slot. 3 There is a chip base 4, and the compression spring 7 is attached to the inside of the interior bottom surface of the chip base 4, and the upper surface of each of the compression spring 7 is fixedly mounted, and the upper surface of the chip base 4 is mounted. The chip body 9, the central surface of the chip body 9 is fixed to the middle position of the upper surface, and the positive electrode 10 is attached. The central portion of the upper surface of the chip body 9 is fixedly mounted with the negative electrode 11, the chip base 4 and each card slot 3 is attached, the chip base 4 Parallel with the card slot 3, the mounting hole 5 is opened at the surface of the metal seat 2, and each mounting hole 5 is provided with a bolt 6, and the metal seat...

Embodiment 2

[0032] Based on the example one, such as Figure 1-5 Since the outer side of the casing 1 is opened on both sides of the bottom surface of the casing, there is a diaphragm 12 in the lower end of the casing 1, and the mounting chamber 12 is fixed in the middle of the bottom surface of the mounting chamber 12 fixed to the drive motor 14, the drive motor 14 side. The roller 15 is provided, and a plurality of sectors 16 are fixedly mounted on one side surface of the roller 15. The output end of the drive motor 14 is fixed to the roller 15, and each fan blade 16 is not in contact with the surface of the mounting chamber 12. There is a safety cover 13 on the front, and the safety cover 13 is rotated by the mounting chamber 12 by a spring homer, and a plurality of heat dissipating holes 18 are opened at the lower end of the outer surface of the casing 1, each of which extends through the side surface of the casing 1. The mounting chamber 12 is inside, and the mounting chamber 12 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com