Device and method for measuring electrical explosion temperature distribution of metal wire

A technology of temperature distribution and metal wire, applied in the field of rapid temperature distribution measurement, it can solve the problems of not being able to measure the change of temperature with space, unable to accurately locate the temperature, and unable to measure the temperature distribution with high spatial and temporal resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

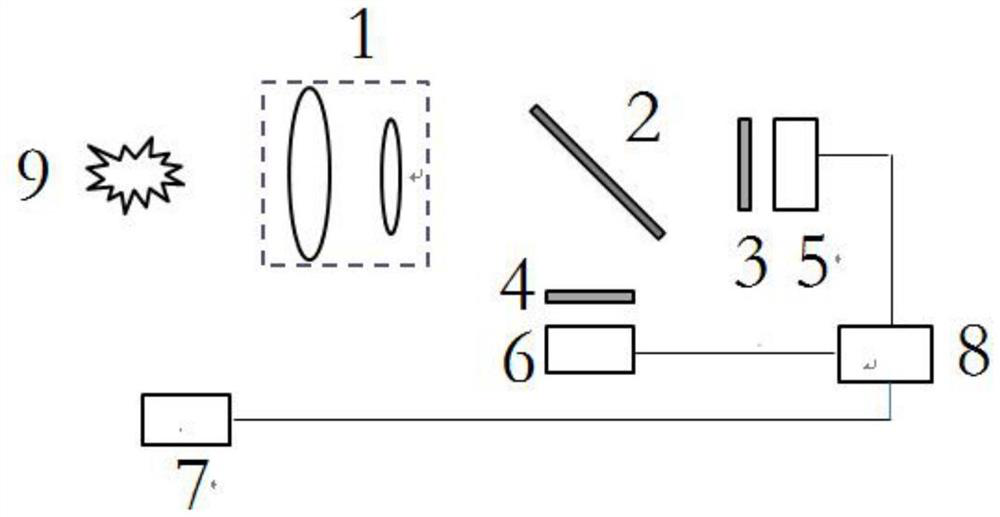

[0029] Such as figure 1 As shown, a device and method for measuring the temperature distribution of a metal wire electric explosion, including: an optical imaging lens 1, a beam splitter 2, a first narrow-band filter 3, a second narrow-band filter 4, a first array optical Sensor 5, second array optical sensor 6, explosion initiation information acquisition module 7 and shutter control module 8, optical imaging lens 1 is fixed in front of wire explosion source 9, and beam splitter is arranged at the rear end of optical imaging lens 1 2. The beam splitter 2 divides the imaging of the explosive source 9 by the optical imaging lens 1 into two paths, and the two optical paths respectively have a first narrow-band filter 3 and a first array optical sensor 5, and a second narrow-band filter 4 and the second array optical sensor 6; the first array optical sensor 5 and the second array optical sensor 6 provide the final imaging detection information to the explosion initiation informat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com