Finned tube heating surface tube structure and coal economizer

A heating tube and heating surface technology, applied in the direction of feed water heaters, preheating, tubular elements, etc., can solve the problems of fly ash wear, achieve the effects of reducing wear, reducing impact force, and increasing the temperature of the medium in the pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

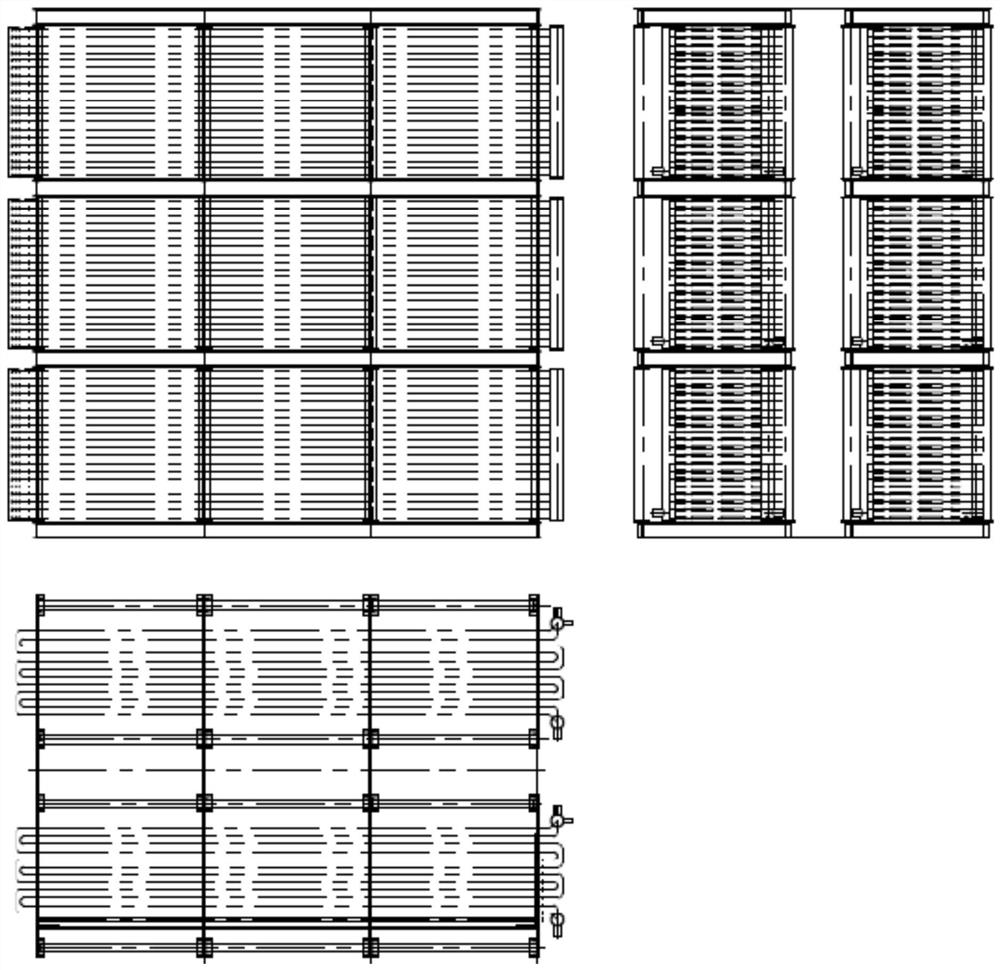

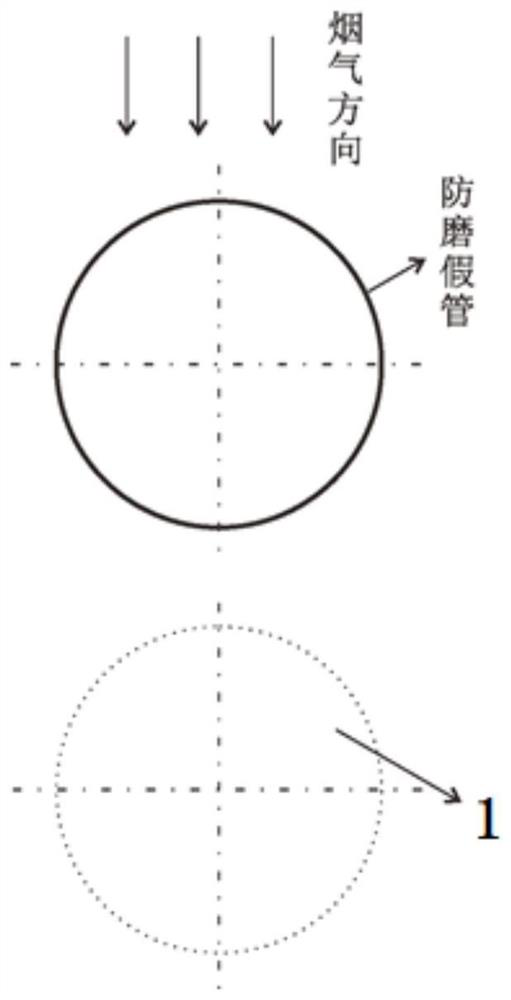

[0030] refer to Figure 2-5 , a finned tube heating surface structure, including a heating tube 1, and fins 2 and wear plates 3 connected thereto.

[0031] Multiple anti-wear plates are arranged along the circumference of the heat-receiving tube and distributed radially, the length direction of the wear-resistant plates is arranged along the axial direction of the heat-receiving tube, and multiple fins 2 are arranged in parallel, and the fins are arranged along the radial direction of the heat-receiving tube.

[0032] Multiple anti-wear plates are arranged radially in the shape of a fan, and the arc surface of the fan is facing the direction of the flue gas. Since the anti-wear plates are set at a certain slope, the fly ash particles in the boiler flue gas directly impact on the anti-wea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com