Reinforced passive ventilation system suitable for arch kiln folk house and construction technology thereof

A ventilation system and reinforcement technology, applied in the direction of ventilation system, heating method, space heating and ventilation, etc., can solve the problems that the mortar surface layer and the kiln face cannot be tightly combined, the kiln face is tilted forward and damaged, and ventilation cannot be exchanged. , to achieve the effect of preventing the decrease of moisture strength, strengthening the connection and enhancing the bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

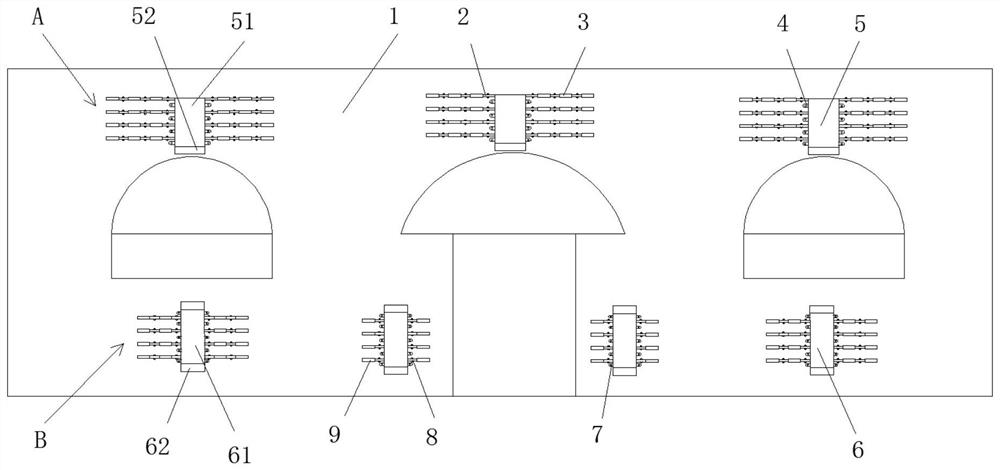

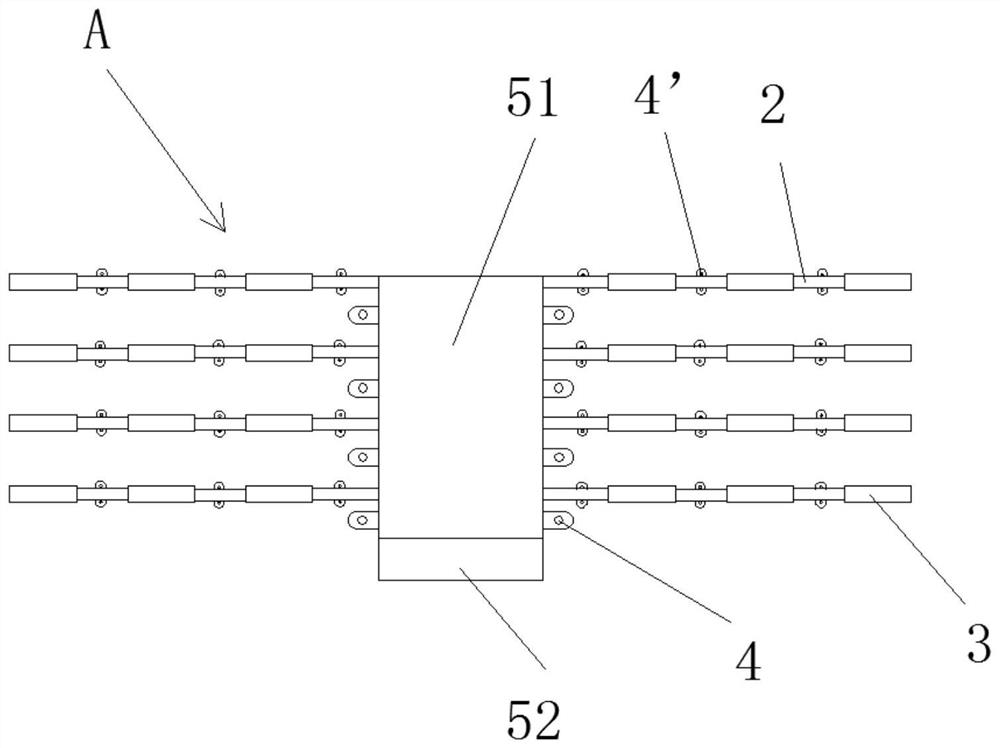

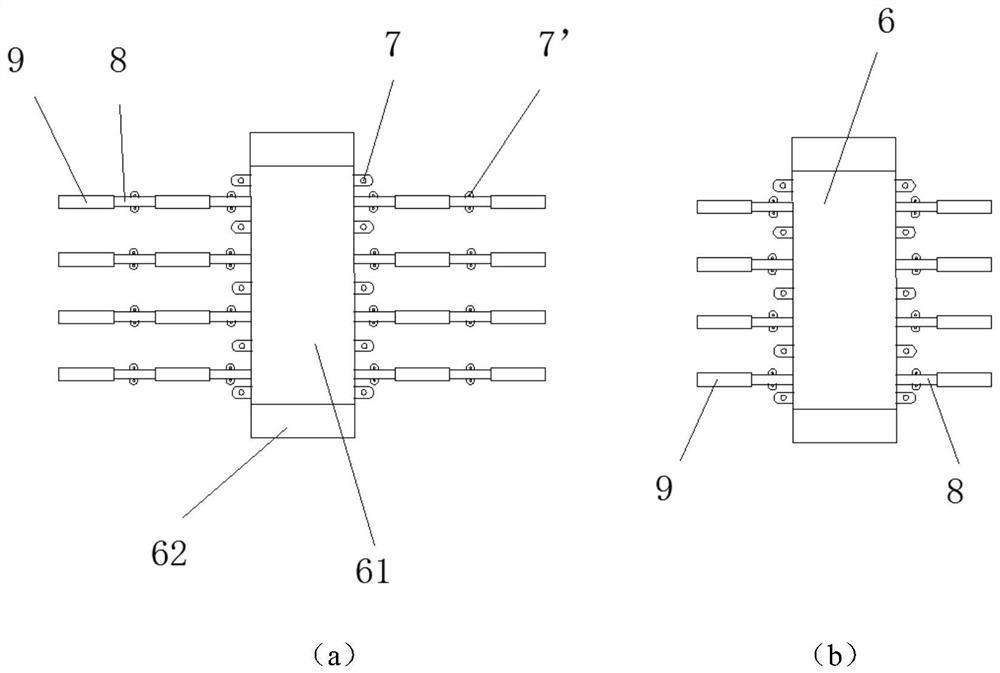

[0026] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the reinforced passive ventilation system suitable for Wanyao dwellings of the present invention has a Guanyao, and the Suyao kiln has a kiln face 1, a kiln roof 15, several kiln holes, and a mortar surface layer 17 located on the outer side of the kiln face. The reinforced passive ventilation system applicable to the dwellings in Suan Kiln also has several air inlet systems A located at the upper part of the kiln face 1 and the bottom of the kiln roof 15, and several air outlet systems B located at the lower part of the kiln face 1.

[0027] Each of the air intake systems A has a main air intake duct 5, several branch air intake ducts 2, several external air intake passages 3 that pass (cross) the mortar surface layer 17, and are installed on the main air intake duct Several air inlet switch valves 12, several kiln top air inlet pipes 10, and several internal air outlets ...

Embodiment 2

[0030] Embodiment 2: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the construction technology (construction method) of the reinforced passive ventilation system applicable to the dwellings in Suyao includes the following process steps:

[0031] Step 1, construction measurement: measure the dimensions of the kiln face 1 and the kiln roof 15, and mark the intended installation position of the components;

[0032] Step 2, component selection: according to the size of the kiln face 1 and the kiln roof 15, select the external air inlet passage 3, the branch air inlet pipe 2, the main air inlet pipe 5, the air inlet switch valve 12, the kiln Top air inlet pipe 10, internal air outlet 11, external air outlet channel 9, branch air outlet pipe 8, main air outlet pipe 6, switch valve 13, internal air inlet 14, first expansion screw to sixth expansion screw;

[0033] Step 3, slotting and perforating: According to the specification and size of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com