Controlling the position of turbine guide vanes and of a coolant flow

A technology of turbines and guide vanes, applied in electrical control, engine control, machine/engine, etc., can solve problems such as carbon deposition, and achieve cost-saving and space-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

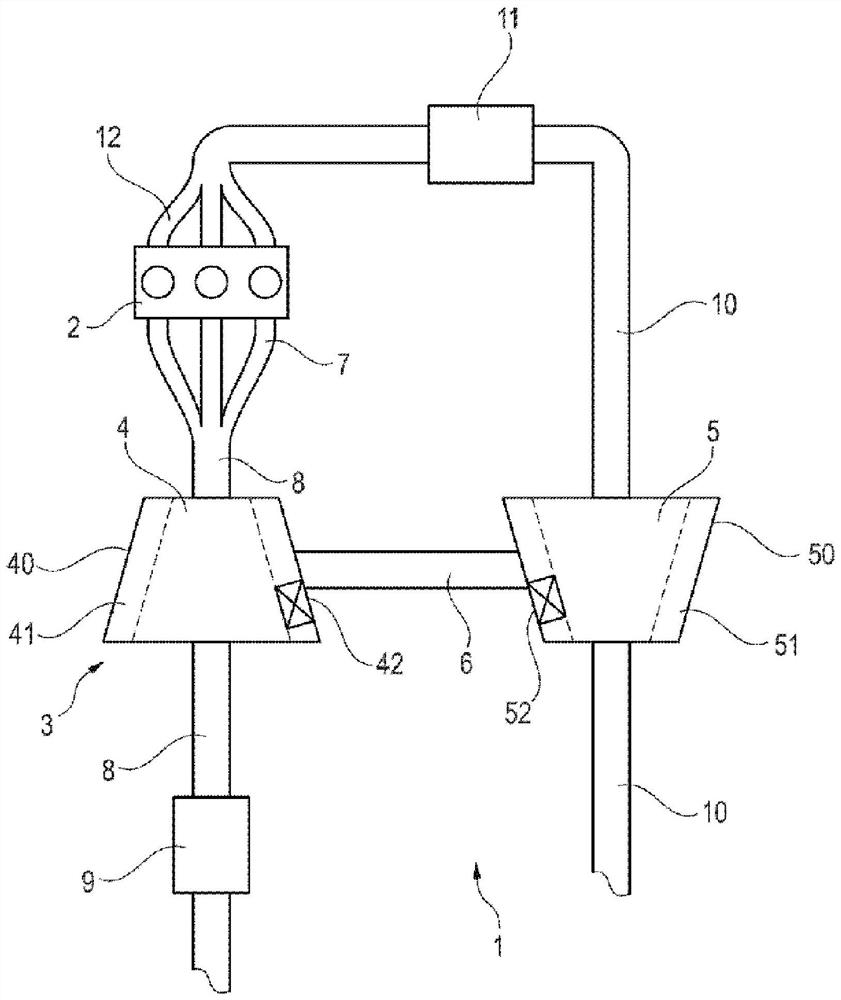

[0036] exist figure 1A component 1 for an internal combustion engine 2 with a turbocharger 3 is shown in . The turbocharger 3 has a turbine 4 and a compressor 5 , the impellers of which are connected to each other for common rotation by means of a shaft in a bearing 6 . according to figure 1 , the internal combustion engine 2 has three cylinders, but is not limited thereto. From the internal combustion engine 2 , exhaust gases are discharged from the cylinders via an exhaust line 7 , which converges via a manifold to form an exhaust duct 8 . The turbine 4 is arranged in the exhaust tract 8 downstream of the internal combustion engine 2 . The turbine wheel is driven by the exhaust gas flow produced by the internal combustion engine 2 by burning fuel. The rotation of the turbine wheel is transmitted to the compressor wheel through the shaft.

[0037] A catalytic device 9 for exhaust gas purification is arranged downstream of the turbine 4 . As catalytic devices, for exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com