Fabricated point type connection wall structure

A wall structure and prefabricated technology, applied in building construction, covering/lining, construction, etc., can solve problems such as wall cracking and bulging, and achieve the effects of cost saving, small deviation, and less material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

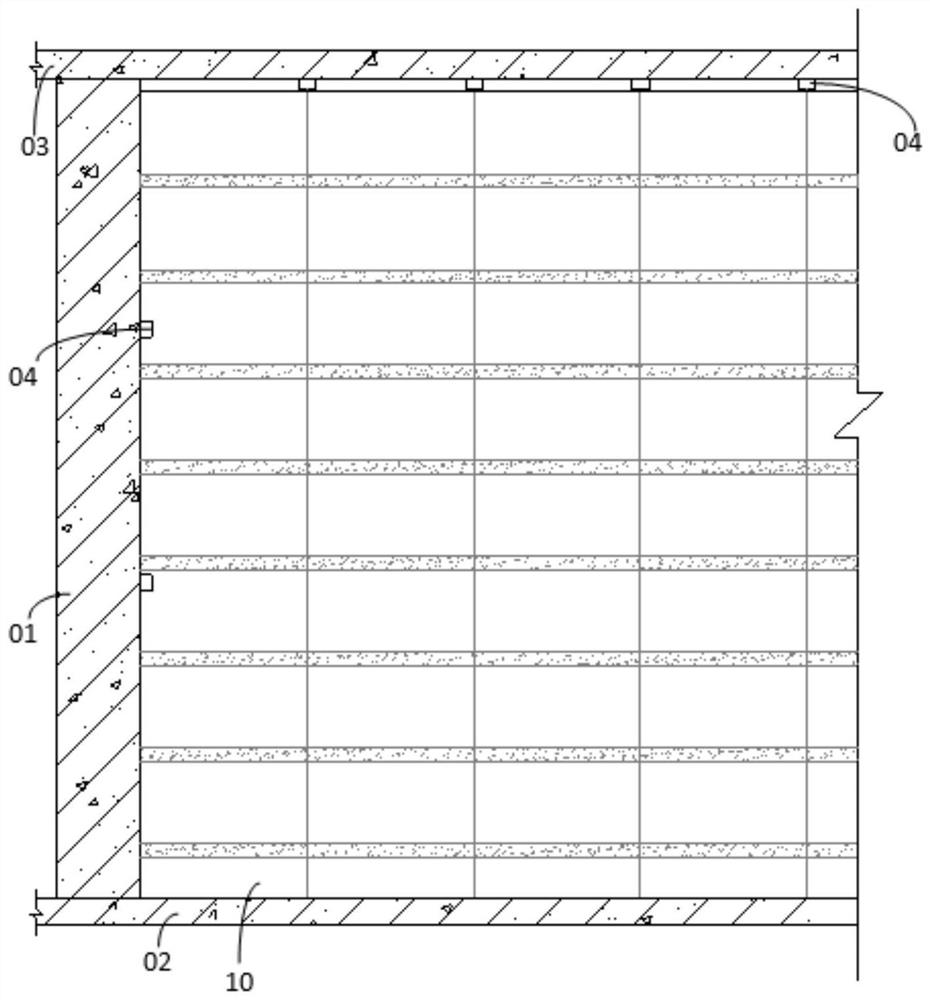

[0036] refer to figure 1 As shown in the figure, a prefabricated point-type connection wall structure is shown, and the wall structure at least includes a first wall formed by splicing several strip boards 10, and a second wall formed by splicing several decorative panels 30. wall.

[0037] Preferably, the first wall and the second wall are arranged in parallel and fixed via U-shaped slots 04 provided on the building support structure. The building support structure includes but is not limited to a frame structure composed of columns 01 , bottom plates 02 and top beams 03 .

[0038] Preferably, spacers 20 are provided between the first wall and the second wall. The distance relationship between the first wall and the second wall can be controlled by the block 20 .

[0039] Preferably, several slits 13 are arranged transversely on the strip 10 . The strips 10 are gypsum boards.

[0040] Further, several holes 14 are longitudinally arranged in the strip 10 . Therefore, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com