Extrusion prestress pier body formwork deformation preventing device and design method thereof

A technology of deformation device and design method, which is applied in the direction of formwork/formwork/working frame, bridge construction, erection/assembly of bridges, etc., and can solve problems such as deformation of pier body formwork, large gaps in pier body formwork, leakage of concrete slurry, etc. Achieve the effect of simple structure, reasonable design and low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

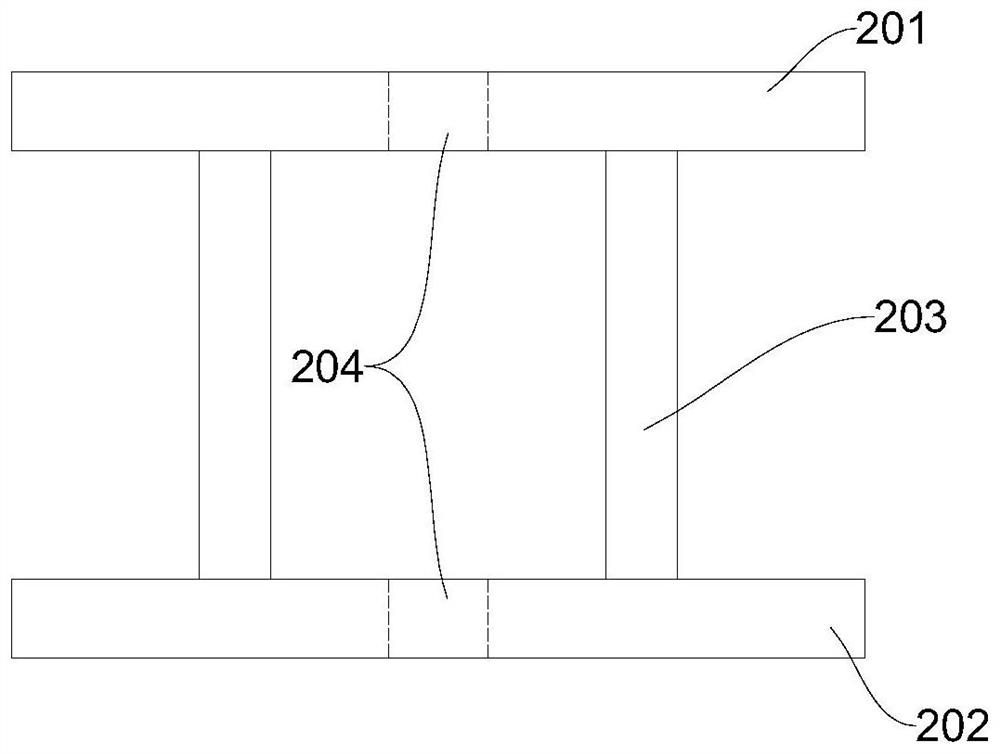

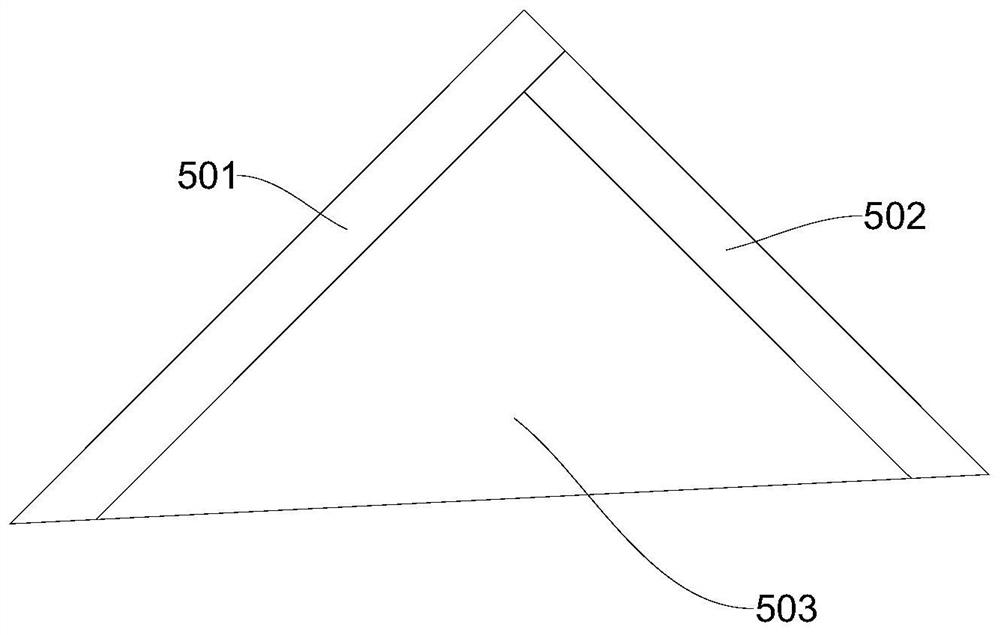

[0052] Please refer to Figure 1 to Figure 4 , the existing pier formwork 1 is a frame with a rectangular symmetrical structure, wherein each side of the rectangular frame includes a straight line segment and an arc segment. In order to fix this type of pier formwork 1, the present embodiment provides an extruded prestressed pier formwork anti-deformation device, including prestressed beams 2 and connectors corresponding to the side walls of the pier formwork 1, At least one side of the prestressed beam 2 is in contact with the outer wall of the pier formwork 1, and two adjacent prestressed beams 2 are detachably fixedly connected by connectors; the prestressed beam 2 has an arc structure, and the prestressed beam 2 Both ends extend toward the direction away from the outer wall of the pier formwork 1 .

[0053] At the same time, the above-mentioned prestressed beam 2 is provided with a pressure plate 3 on the side close to the outer wall of the pier formwork 1, and the prestr...

Embodiment 2

[0061] On the basis of Embodiment 1, this embodiment provides a design method of the extrusion prestressed pier body anti-formwork deformation device as described in the above Embodiment 1, mainly including the design method of the prestressed beam 2, and the design process includes :

[0062] a. Calculate the lateral pressure F applied to the pier formwork 1 by the newly poured concrete;

[0063] Wherein, the calculation formula of the lateral pressure F can be calculated by using the calculation formula in the prior art, for details, please refer to formula 1 and formula 2.

[0064] Formula one: Among them, γ c is the gravity density of concrete, t 0 is the initial setting time of newly poured concrete, β 1 is the correction coefficient for the effect of admixtures (where 1.0 is used when no admixtures are added), β 2 Correction coefficient for concrete slump effect (where 0.85 is taken when the slump is less than 30mm; 1.0 is taken when the slump is 50-90mm; 1.15 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com