Take-up and pay-off frame based on lifting high-speed braiding machine

A technology for high-speed knitting machines and take-up and take-up of wires, applied in the field of knitting machines, can solve problems such as occupying a large floor area, occupying a large area, affecting management and maintenance, etc., to reduce the occupied area, improve stability, and reduce occupied space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

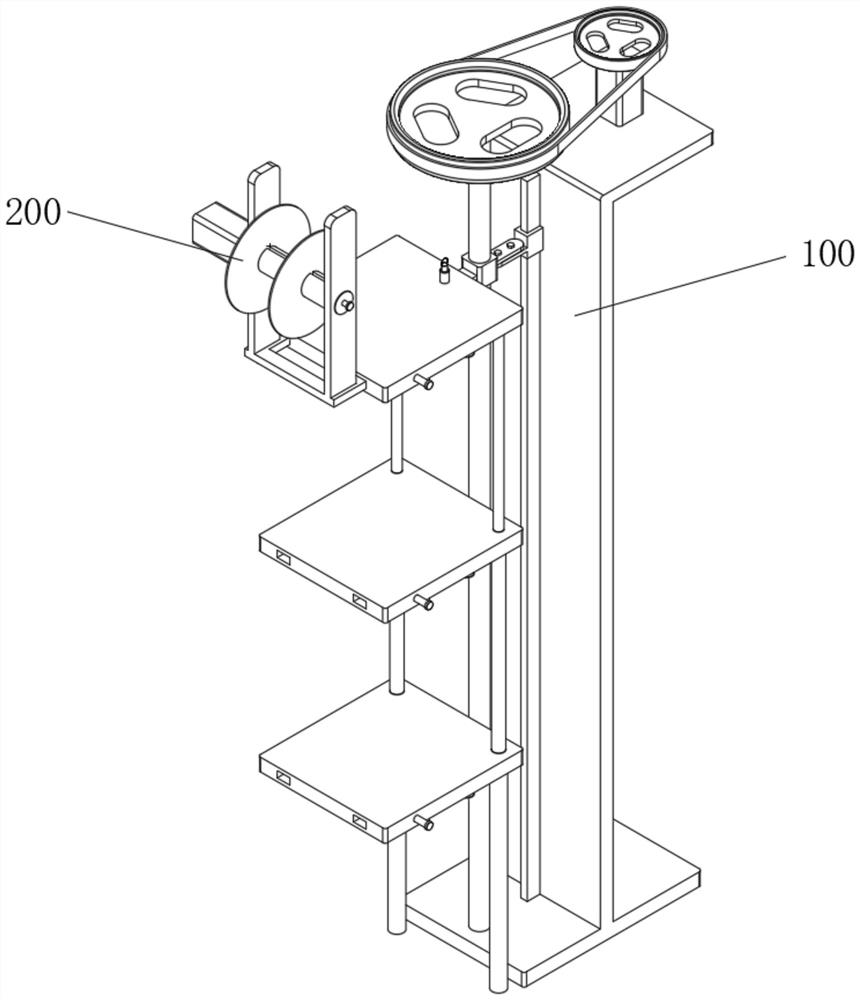

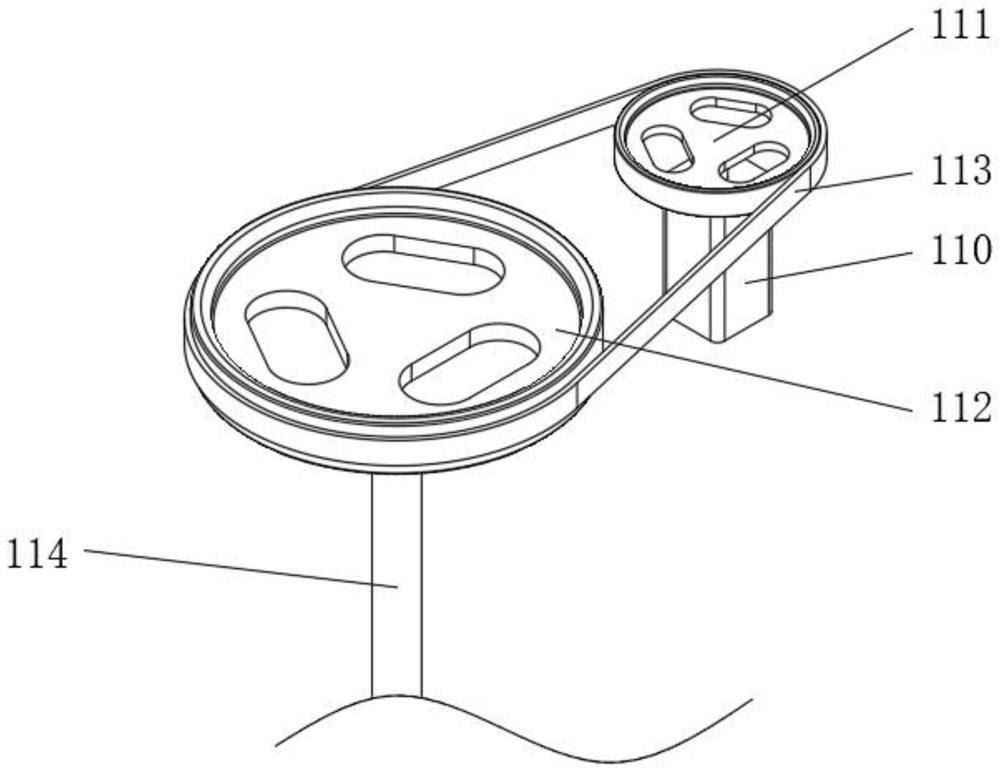

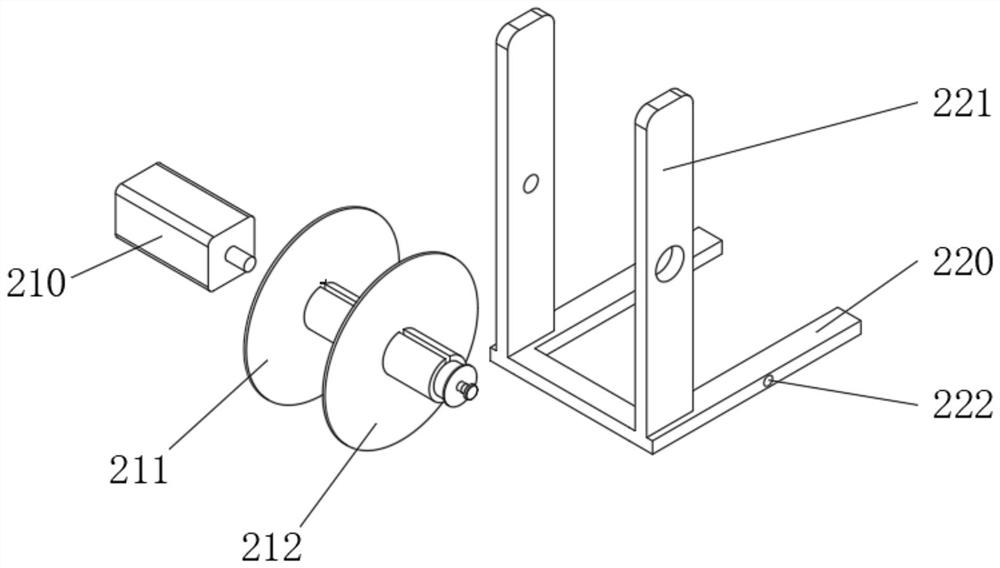

[0050] see Figure 1-Figure 11As shown, a take-up and pay-off frame based on a lift-type high-speed knitting machine is provided, including a lift device 100 and a take-up and pay-off device 200 mounted on the lift device 100. The lift device 100 includes a lift motor 110, preferably a stepper motor, as shown in the present invention As known to those skilled in the art, a stepper motor is a motor that converts electrical pulse signals into corresponding angular or linear displacements. Each time a pulse signal is input, the rotor rotates by an angle or moves forward one step. The output angular displacement or linear displacement is proportional to the number of input pulses, and the rotational speed is proportional to the pulse frequency. A small pulley 111 is coaxially connected above the lifting motor 110 , the side of the small pulley 111 is provided with a large pulley 112, a first screw rod 114 is coaxially connected under the large pulley 112, a belt 113 is sleeved bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com