A kind of nickel hydroxide precursor and its preparation method, positive electrode material

A technology of nickel hydroxide and precursors, applied in the direction of nickel compounds, chemical instruments and methods, positive electrodes, etc., can solve the problems of increased particle specific surface area, difficulty in controlling the number of nucleation, aggravated agglomeration, etc., to reduce the pH value , Product quality is stable, and the effect of avoiding the cost of impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

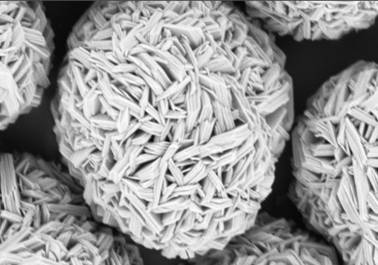

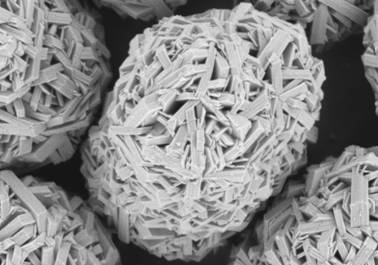

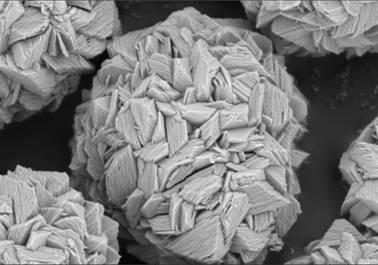

Image

Examples

Embodiment 1

[0033] The preparation of nickel hydroxide precursor comprises the following steps:

[0034] (1) Ni according to the molecular formula 0.88 co 0.09 mn 0.03 (OH) 2 Ingredients, nickel sulfate, cobalt sulfate, and manganese sulfate are prepared into a mixed salt solution with a total metal ion concentration of 2mol / L according to the molar ratio of nickel, cobalt, and manganese being 0.88:0.09:0.03.

[0035](2) Add deionized water into the reaction kettle with a volume of 1m³, control the stirring speed at 280r / min, raise the temperature to 67.5°C, add ammonia water and sodium hydroxide solution into the reaction kettle to form the bottom liquid of the reaction kettle; make the reaction The concentration of ammonia water in the bottom liquid was 12g / L, the pH value was adjusted to 11.80, and nitrogen gas was continuously fed for 3 hours before feeding.

[0036] (3) Under the atmosphere of nitrogen protection, the mixed salt solution in step (1), the precipitating agent with ...

Embodiment 2

[0043] The preparation of nickel hydroxide precursor comprises the following steps:

[0044] (1) Ni according to the molecular formula 0.70 co 0.05 mn 0.25 (OH) 2 Ingredients, nickel sulfate, cobalt sulfate, and manganese sulfate are prepared into a mixed salt solution with a total ion concentration of 2.2mol / L according to the molar ratio of nickel, cobalt, and manganese being 0.70:0.05:0.25.

[0045] (2) Add deionized water into the reaction kettle with a volume of 100L, control the stirring speed at 300r / min, raise the temperature to 60°C, add ammonia water and sodium hydroxide solution into the reaction kettle to form the bottom liquid of the reaction kettle; make the reaction The concentration of ammonia water in the bottom liquid was 10g / L, the pH value was adjusted to 11.50, and nitrogen gas was continuously fed for 3 hours before feeding.

[0046] (3) Under the atmosphere of nitrogen protection, the mixed salt solution in step (1), the precipitating agent with a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com