Ink box packaging assembly and ink box assembly

A technology of packaging components and ink cartridges, which is applied in printing and other directions, can solve the problems of time-consuming and cost, and achieve the effect of saving labor cost and time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

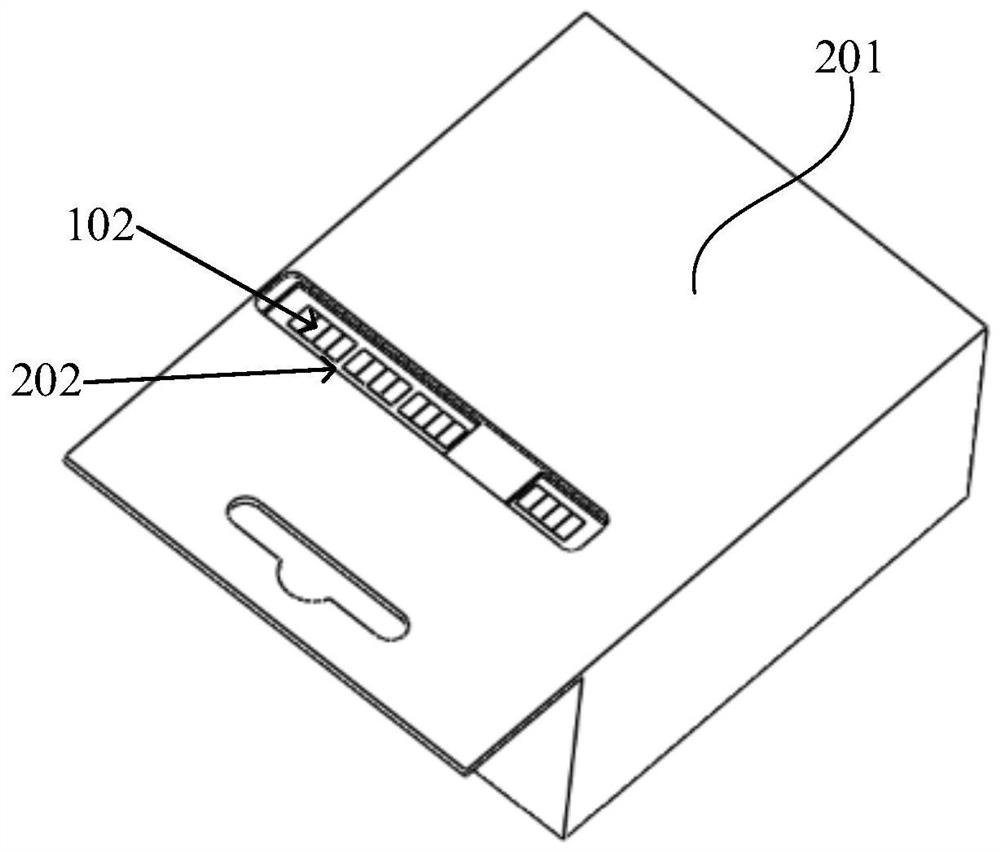

[0054] Such as figure 1 As shown, the present invention provides a cartridge packaging assembly 2, and the surface of the ink cartridge 1 has a first region 101, and the ink cartridge pack assembly 2 includes a first housing 201 and a sealing film 205, and the first housing 201 has a to accommodate at least one. The receiving chamber of the ink cartridge 1, the first housing 201 is opened, and at least one first opening 202 is provided, and the first opening 202 is coupled to the receiving chamber, and the first opening 202 is disposed opposite the first region 101. The sealing film 205 seals the outer side of the ink cartridge 1 and in the first housing 201, and there is a gap between the sealing film 205 and the first region 101. A conductive sheet 102 is provided in the first region 101, and the conductive sheet 102 is coupled to the chip within the ink cartridge 1.

[0055]The ink cartridge 1 is mounted with a chip, and the chip is used to record the remaining ink of the ink c...

Embodiment 2

[0071] The second embodiment is not repeatedly described in the same portion as in Example 1, and only the different portions are described. In the first embodiment, the number of the first opening 202 is one, in Example 2, the number of the first opening 202 is plural.

[0072] The accommodating cavity contains several ink cartridges 1, and the plurality of first regions 101 are disposed opposite several first opening 202. Wherein, the number of first opening 202 can be consistent with the number of the first region 101, and the first opening 202 is provided with one or one of the first region 101. Or, if figure 1 As shown, the number of the first opening 202 may be less than the number of the first region 101, and the portion first opening 202 corresponds to a plurality of first region 101.

[0073] The accommodating cavity content is ranging from the ink cartridge 1, and several ink cartridges 1 are arranged in parallel to the receiving cavity of the first housing 201, and the ...

Embodiment 3

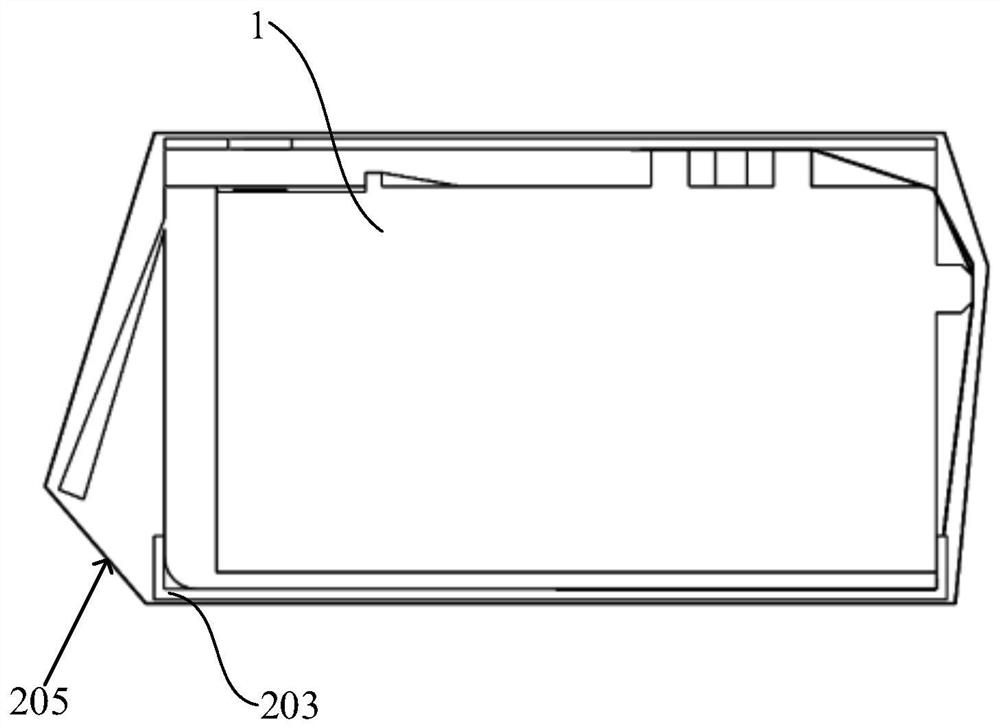

[0075] The third embodiment is no longer repeatedly described in the same portion as in Example 1, and only the different portions are described. In the first embodiment, the second housing 203 is only surrounded by the side wall of the ink cartridge 1, in Example 3, the second housing 203 surrounds the entire ink cartridge 1.

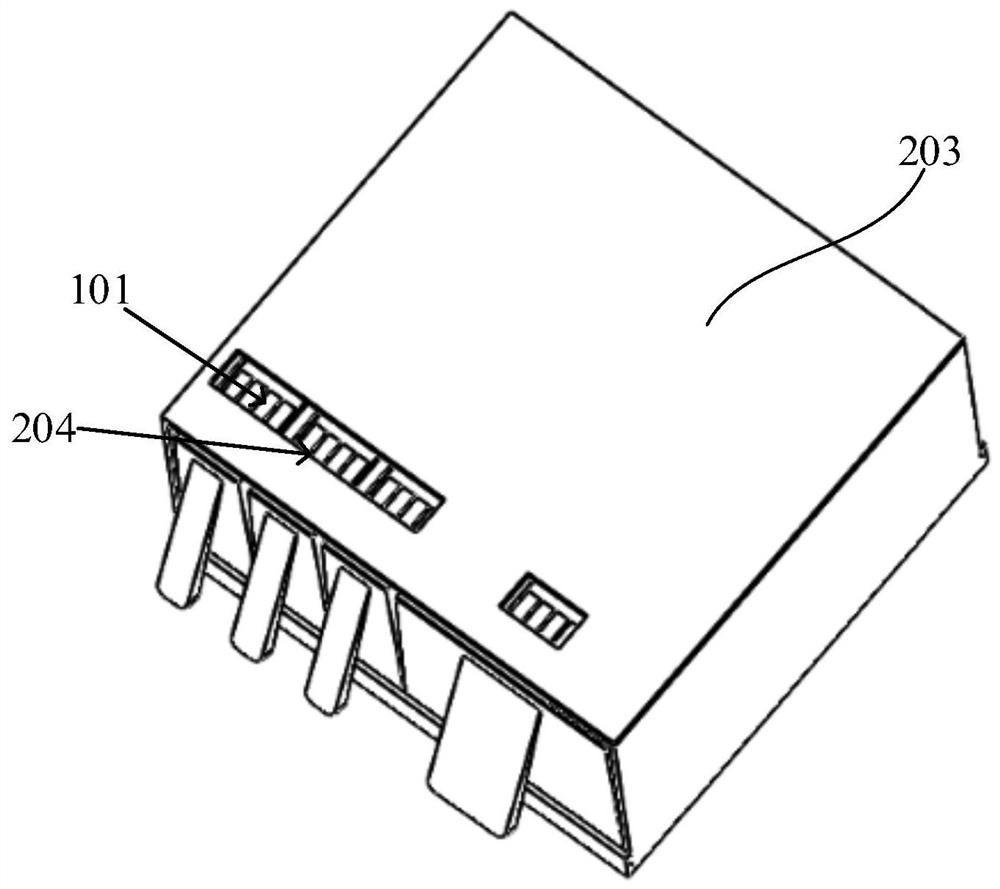

[0076] Such as Figure 2 - Figure 5 , Figure 8 - Figure 10 As shown, the second opening 204 is provided on the second housing 203, and the second opening 204 is connected inside the second housing 203, and the second opening 204 is disposed opposite the first region 101.

[0077] The cartridge packaging assembly also includes at least one second housing 203, and the second housing 203 is disposed in the receiving chamber, and the second housing 203 is covered in the outer side of the ink cartridge 1. The second opening 204, the position of the second opening 204 is opposed to the position of the first region 101 on the ink cartridge 1, so that the ink cartr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap