Garbage compression treatment equipment

A technology for processing equipment and garbage compression, applied in the direction of presses, manufacturing tools, etc., can solve the problems of increasing the operator's labor, easy to get stuck in the chassis, affecting work efficiency, etc., to ensure the compaction effect, ensure the sealing effect, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

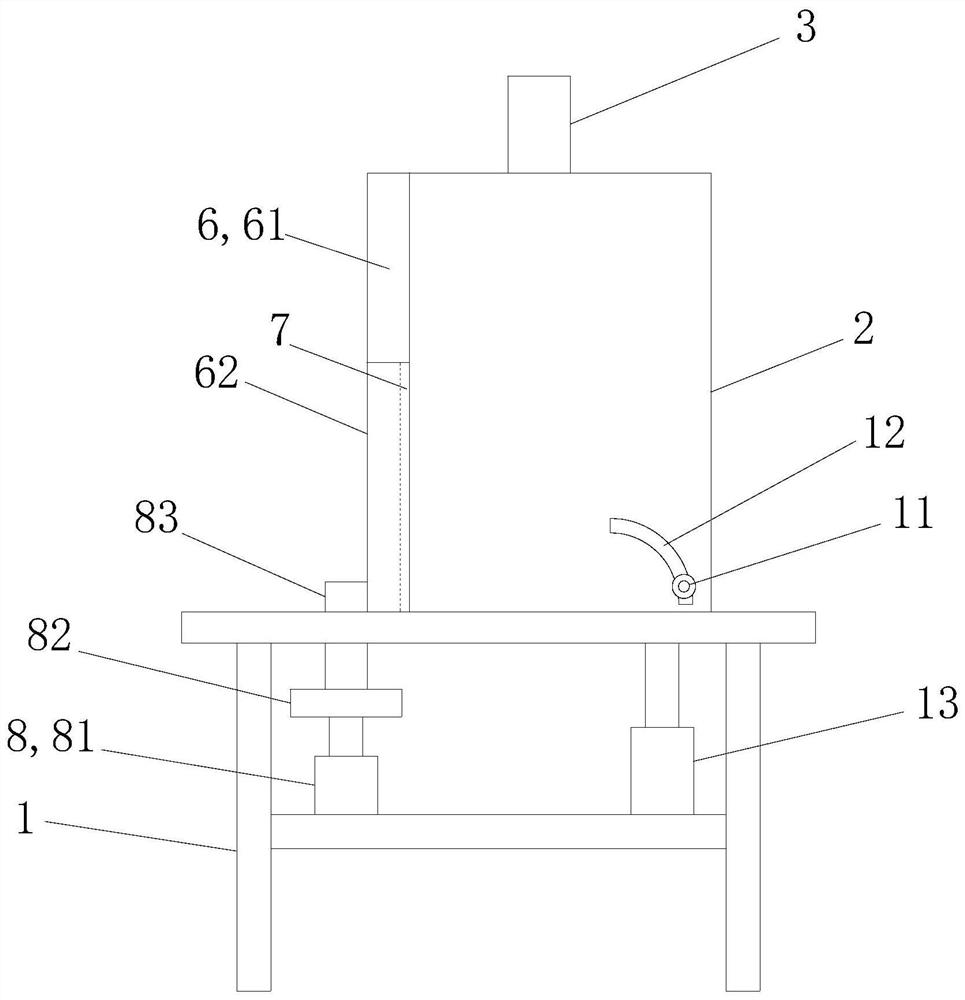

[0023] See Figure 1 to Figure 4 , the garbage compression processing equipment of the present embodiment comprises a frame 1 and a casing 2 arranged on the frame 1, an oil cylinder 3 is provided on the top of the casing 2, and a pressing plate 4 connected with the oil cylinder 3 is provided in the casing 2, The pressure plate 4 is provided with a plurality of guide rods 5 positioned around the oil cylinder 3 , and the plurality of guide rods 5 run through the top of the box body 2 . The side of casing 2 is provided with door panel assembly 6, and door panel assembly 6 comprises fixed plate 61 and movable plate 62, and movable plate 62 is arranged on the below of fixed plate 61, and the upper end of movable plate 62 is hinged on the fixed plate 61 by hinge. The lower end is provided with a rubber cushion 7 between the box body 2 and the movable plate 62, and the rubber cushion 7 is arranged on the box body 2; the frame 1 is also provided with a positioning mechanism 8 for fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com