Nitrile glove automatic production line and production method thereof

An automated production line, nitrile glove technology, applied to other household appliances, household components, household appliances, etc., can solve problems such as poor cleaning effect and impact on product quality, and achieve the effect of stable environmental conditions and guaranteed sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

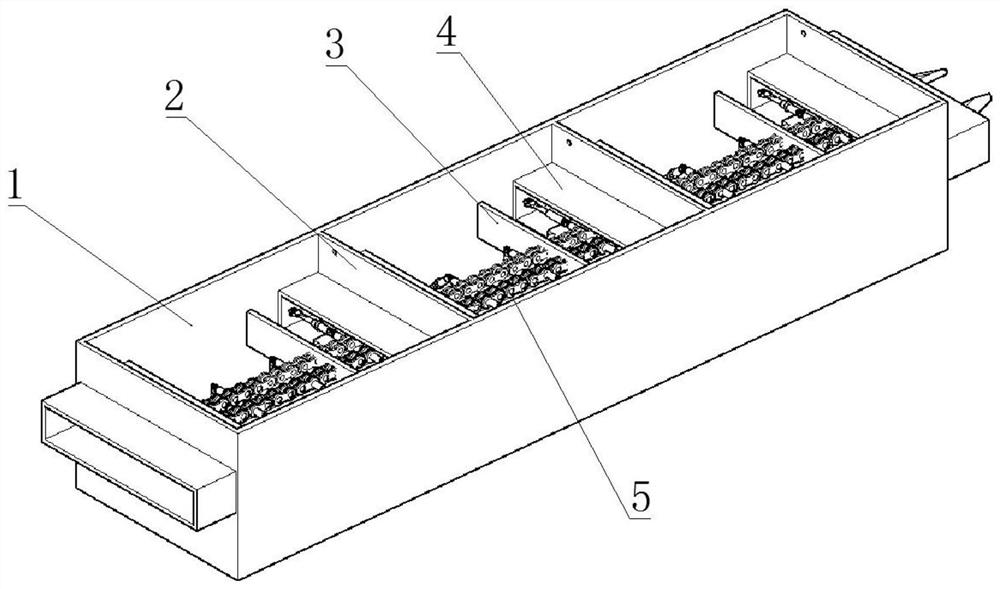

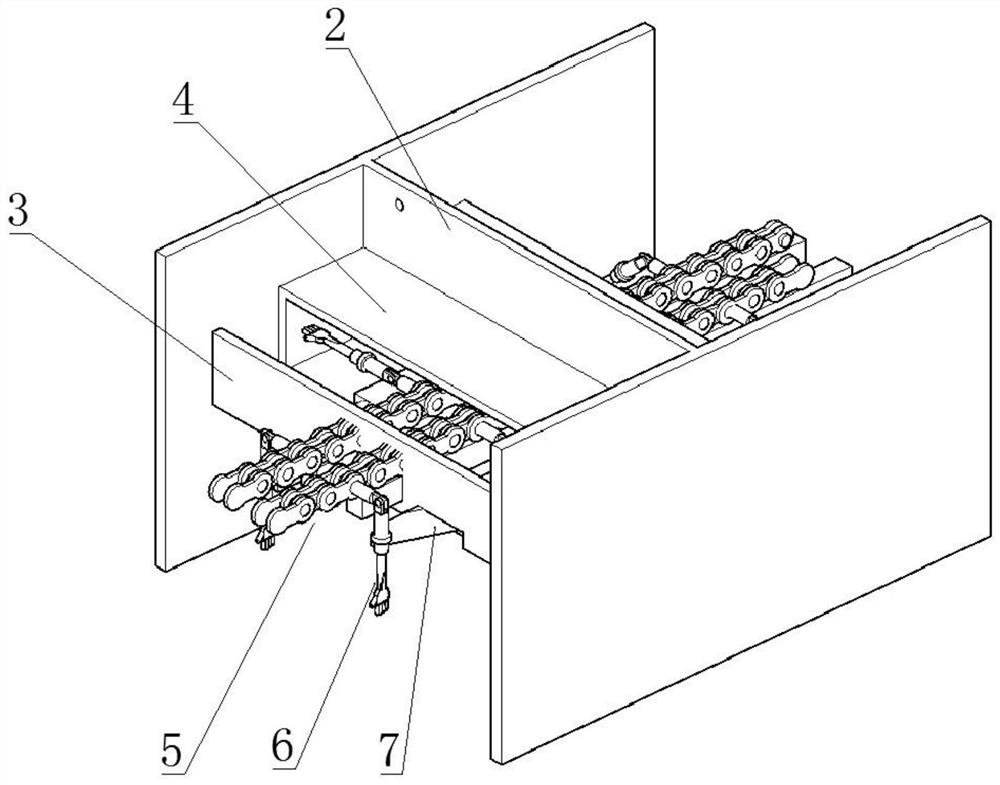

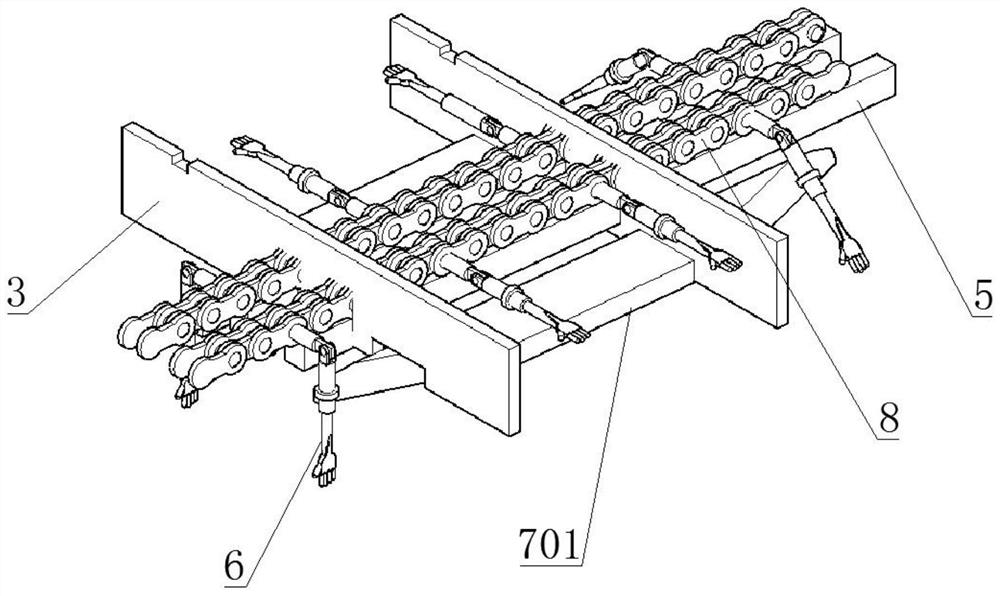

[0035] Such as Figure 1-3 As shown, an automatic production line for nitrile gloves includes a hand mold frame 5, and the hand mold frame 5 runs through several mold washing cavities 1 in turn, and the adjacent mold washing cavities 1 are separated by partitions 2, and the hand mold frame 5 is connected with Several groups of hand models 6 in a linear array along the length direction of the hand formwork frame 5, the side of the same group of hand models 6 on the formwork frame is connected with a sealing plate 3 whose edge fits with the frame tube 4, and a partition plate 2 between adjacent cavities A frame tube 4 is fixed on the outside of the hand mold frame 5, and the two ends of the frame tube 4 are respectively provided with a hand mold guiding mechanism 7, and an exhaust mechanism is arranged above the frame tube 4, and the hand mold frame 5 is rotated and connected with a sprocket. The wheel is hinged with the chain 8, and the chain 8 is connected with the hand model ...

Embodiment 2

[0038] Such as Figure 1-4 As shown, an automatic production line for nitrile gloves includes a hand mold frame 5, and the hand mold frame 5 runs through several mold washing cavities 1 in turn, and the adjacent mold washing cavities 1 are separated by partitions 2, and the hand mold frame 5 is connected with Several groups of hand models 6 in a linear array along the length direction of the hand formwork frame 5, the side of the same group of hand models 6 on the formwork frame is connected with a sealing plate 3 whose edge fits with the frame tube 4, and a partition plate 2 between adjacent cavities A frame tube 4 is fixed on the outside of the hand mold frame 5, and the two ends of the frame tube 4 are respectively provided with a hand mold guiding mechanism 7, and an exhaust mechanism is arranged above the frame tube 4, and the hand mold frame 5 is rotated and connected with a sprocket. The wheel is hinged with the chain 8, the chain 8 is connected with the hand model 6 th...

Embodiment 3

[0041] Such as Figure 1-5 As shown, an automatic production line for nitrile gloves includes a hand mold frame 5, and the hand mold frame 5 runs through several mold washing cavities 1 in turn, and the adjacent mold washing cavities 1 are separated by partitions 2, and the hand mold frame 5 is connected with Several groups of hand models 6 in a linear array along the length direction of the hand formwork frame 5, the side of the same group of hand models 6 on the formwork frame is connected with a sealing plate 3 whose edge fits with the frame tube 4, and a partition plate 2 between adjacent cavities A frame tube 4 is fixed on the outside of the hand mold frame 5, and the two ends of the frame tube 4 are respectively provided with a hand mold guiding mechanism 7, and an exhaust mechanism is arranged above the frame tube 4, and the hand mold frame 5 is rotated and connected with a sprocket. The wheel is hinged with the chain 8, the chain 8 is connected with the hand model 6 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com