An automatic control system for glass edge grinding machine

An automatic control system, glass edging technology, applied in the direction of grinding automatic control device, grinding machine parts, workpiece feed movement control, etc., can solve the problem of low automation, high use threshold, and glass workpiece bursting under force and other issues, to achieve the effect of improving the degree of automation, lowering the operating threshold, and increasing the processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

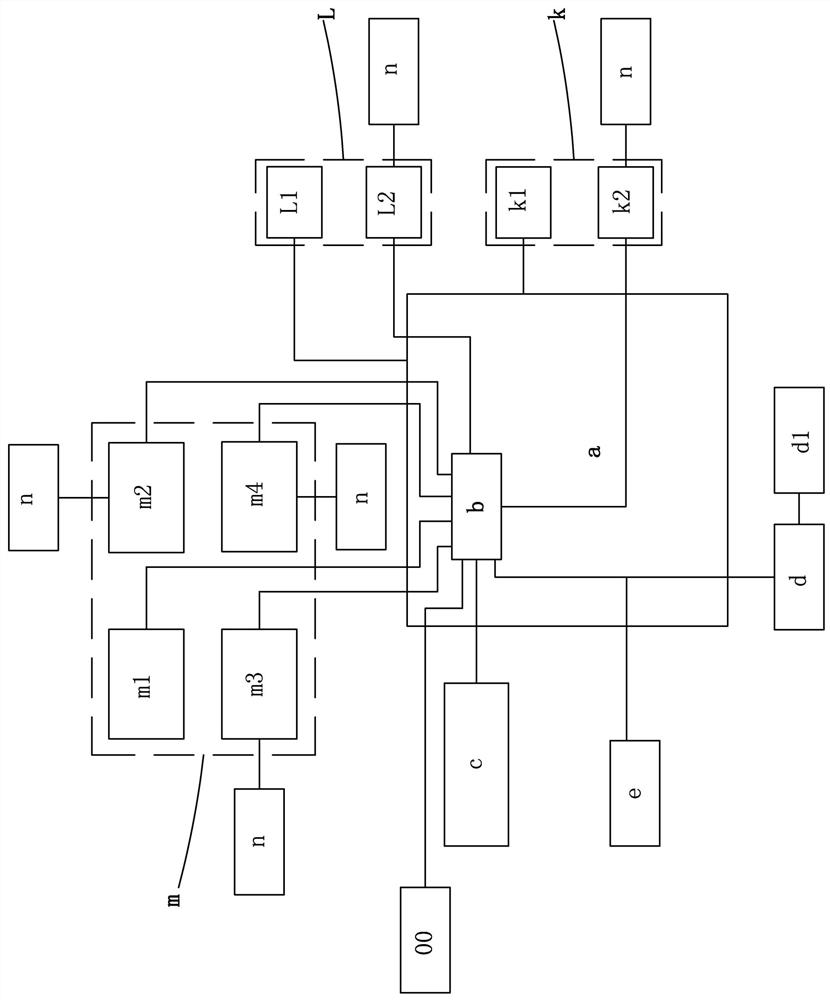

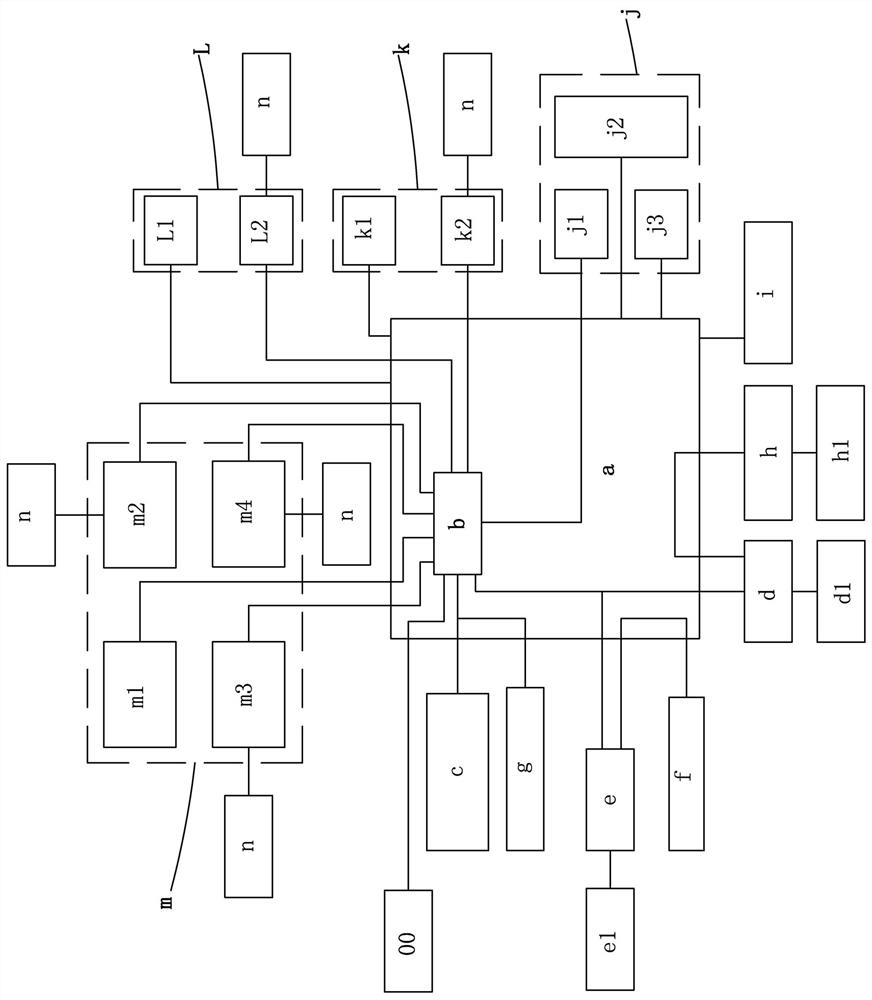

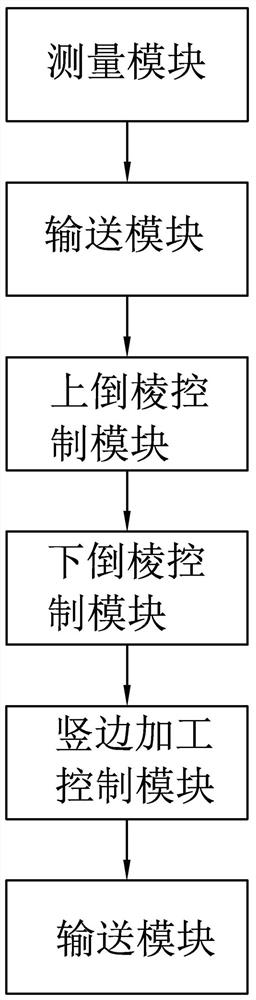

[0045] The realization and advantages of the functions of the present invention will be further described in conjunction with the embodiments and with reference to the accompanying drawings. according to Figure 1-13 As shown, the automatic control system of the glass edging machine includes a central control module a and an input assembly 00 respectively connected to the central control module a by electrical signals, a measuring module c, a conveying module d, an induction electric eye e, an edge guiding positioning module f, an upper Press component control module g, edge detection module h, front lower chamfering control module i, edge trimming control module j, upper chamfering control module k, lower chamfering control module L, side processing control module m, central control module There is a data register b inside a.

[0046] The input assembly 00 of the present invention is used for inputting the operating parameters of the equipment into the central control module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com