Crankshaft positioning mechanism of numerical control end face milling and center hole drilling machine tool

A technology for drilling a center hole and a positioning mechanism, which is used in positioning devices, metal processing mechanical parts, clamping and other directions, can solve the problems of low positioning accuracy, low repeat positioning accuracy, and complex structure, and achieve the effect of improving positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

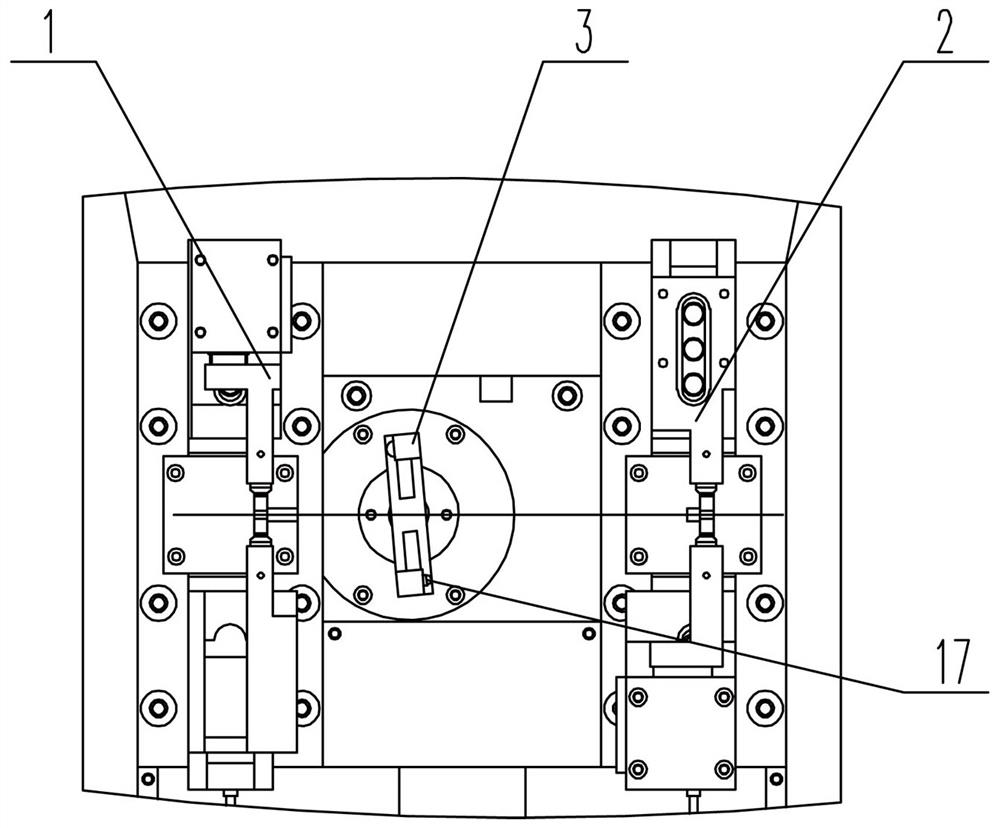

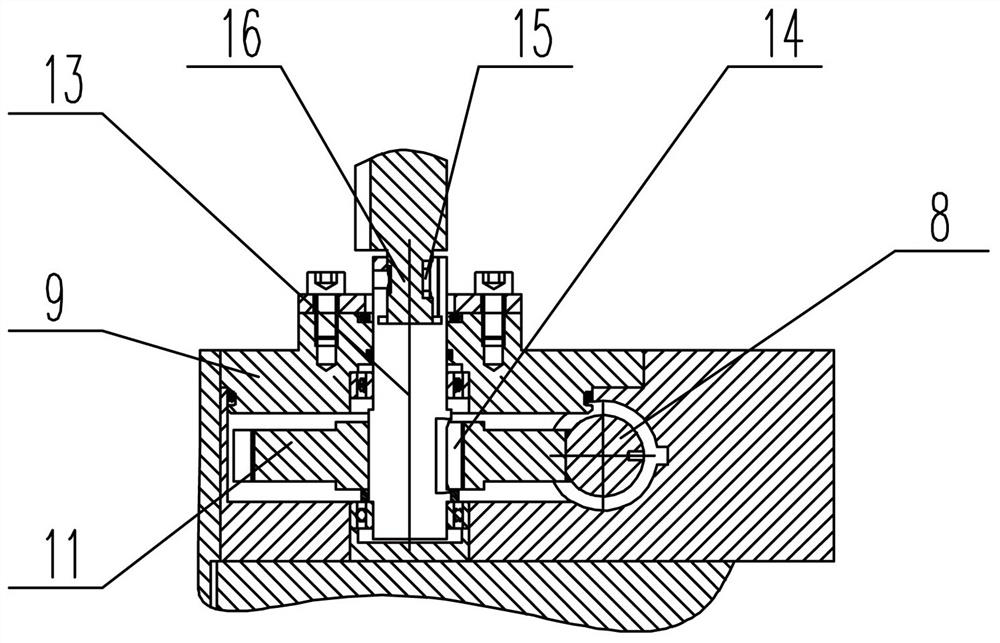

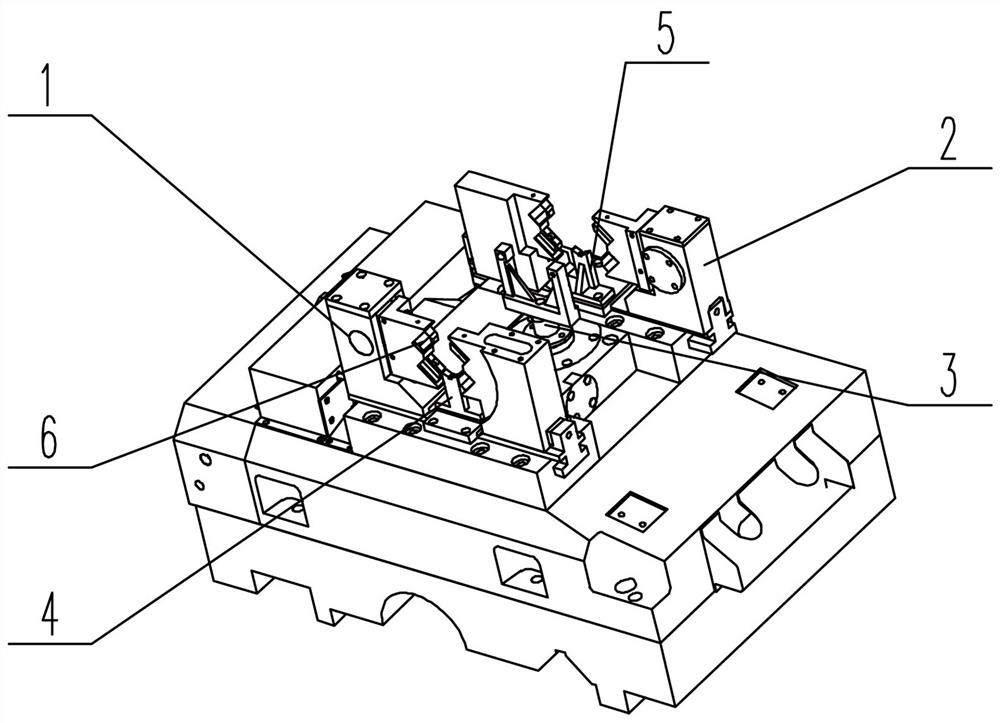

[0021] Such as figure 1 and figure 2 As shown, a crankshaft positioning mechanism of a CNC milling end face drilling center hole machine tool, the left clamping mechanism 1 and the right clamping mechanism 2 are arranged symmetrically on both sides of the base 9, and the left clamping mechanism 1 and the right clamping mechanism 2 are separated. The opening and closing end faces are provided with preload pads 6 which are in contact with the two ends of the crankshaft to be processed, and the left bracket 4 supporting the crankshaft is provided at the bottom of the opening and closing of the left clamping mechanism 1, and clamped on the right The bottom of the mechanism 2 is provided with a right bracket 5 supporting the crankshaft, and the left bracket 4 and the right bracket 5 are connected to the base 9 at the corresponding position; between the left clamping mechanism 1 and the right clamping mechanism 2, a The axial positioning pawl 3 is driven and rotated by the power u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com