Welding tongs of spot welding robot

A technology of robot welding tongs and welding tongs, applied in the field of artwork display, can solve problems such as cables being easily damaged and broken, and achieve the effect of preventing the reduction of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

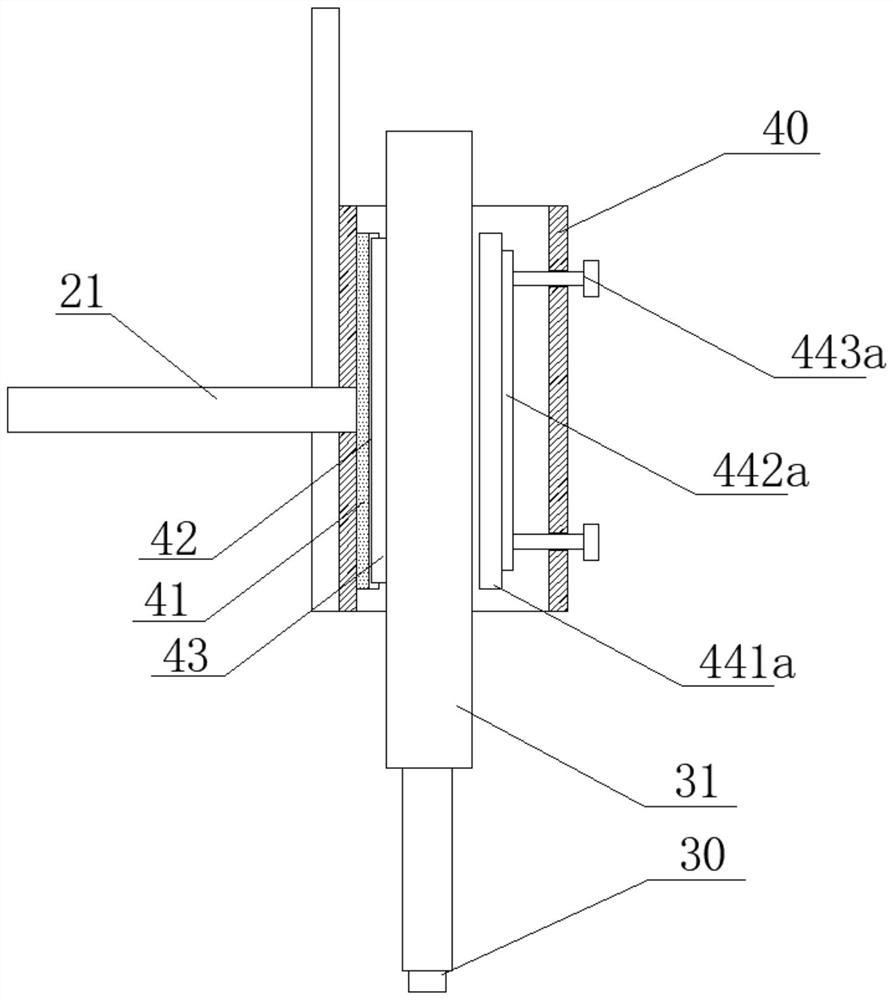

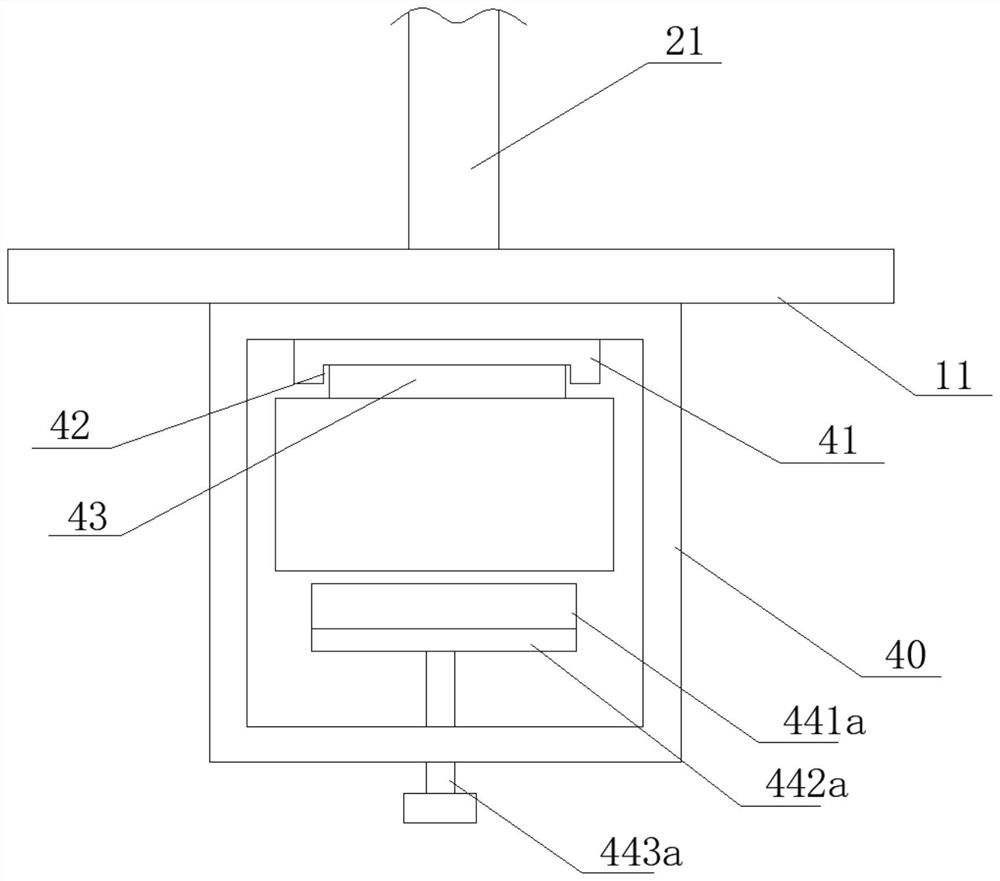

[0034] Such as Figure 2-3 The position-limiting structure 44 includes a plurality of screw rods 443a threaded on one side wall of the connecting seat 40, one end of the screw rod 443a protruding into the connecting seat 40 is connected to the rubber pad 442a in rotation, and the rubber pad 442a is provided with There is an insulating first top plate 441 a, and the conductive column 31 is between the first top plate 441 a and the conductive sliding plate 43 .

[0035] This embodiment is implemented in such a way that the provided screw 443a can drive the rubber pad 442a to move, and the rubber pad 442a can drive the first top plate 441a to move, so that the first top plate 441a squeezes the conductive column 31 into the chute 42 .

Embodiment 3

[0037] Such as Figure 4 The limiting structure 44 includes a through hole 442b disposed on one side wall of the connecting seat 40 and a U-shaped support plate 444b, the support plate 444b straddles the through hole 442b, and the through hole 442b is rotatably provided with Two rotating plates 443b. The end of the rotating plate 443b away from the through hole 442b is rotated to be provided with a second top plate 441b. The rotating plate 443b is connected to the supporting plate 444b through a first spring 445b, and the first spring 445b penetrates through the hole 442b.

[0038] This embodiment is implemented in such a way that the first spring 445b is compressed, so that the first spring 445b applies a thrust to the rotating plate 443b, so that one end of the rotating plate 443b turns into the connecting seat 40, and drives the second top plate 441b to the conductive column 31 A pushing force is applied so that the conductive column 31 is in close contact with the slide g...

Embodiment 4

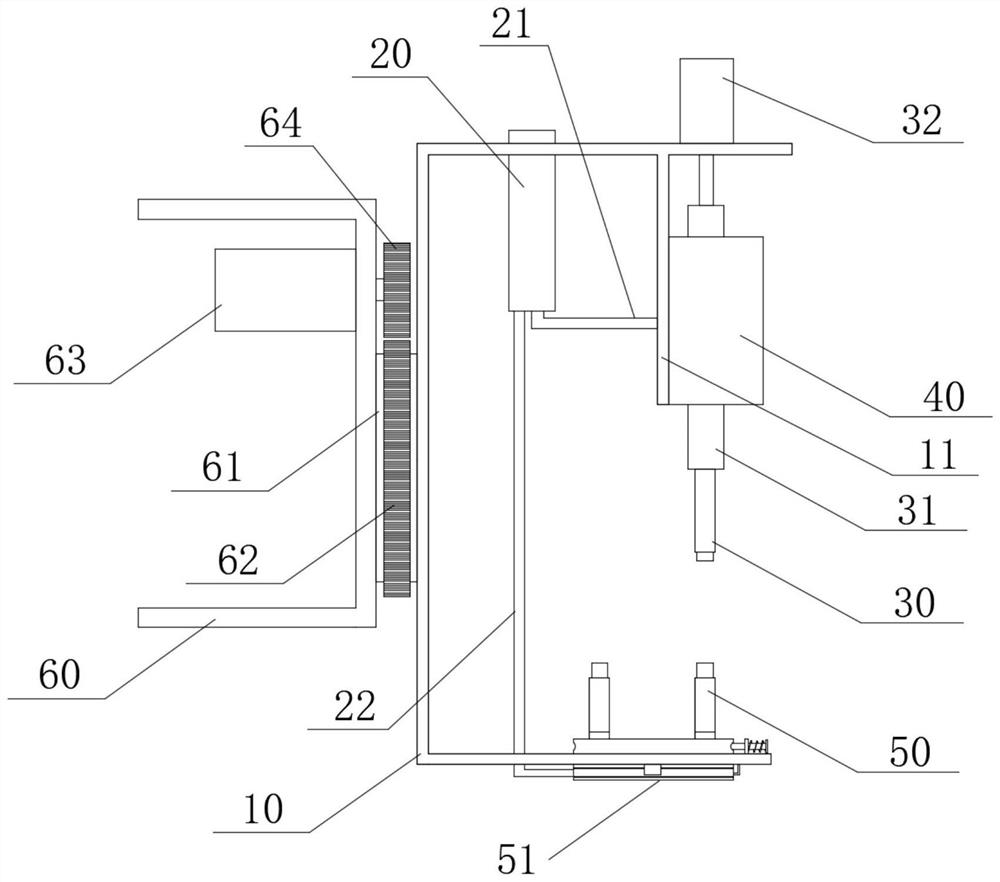

[0040] Such as figure 1 , 5 The conductive seat 51 includes a conductive plate 510 that rotates through the welding tongs arm 10, and a number of insulating connecting plates 513 that are arranged on the welding tongs arm 10 and surround the conductive plate 510. The outer circumference of the conductive plate 510 An annular rotating groove 511 is arranged on the wall, and a conductive ring 512 is sleeved in the rotating groove 511. The conductive ring 512 is connected to the second cable 22, and the connecting plate 513 is fixedly connected to the conductive ring 512. The conductive disk 510 is also provided with several threaded holes 518 that run through the conductive disk 510. Several threaded holes 518 are arranged in a circular shape. Above, the threaded hole 518 is threaded with a conductive threaded column 519 , and the conductive threaded column 519 is connected to the second electrode 50 , and the welding clamp arm 10 is also provided with a blocking structure that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com