Frame beam bottom paint spraying device

A technology of spraying device and frame beam, which is applied in the direction of spraying device, etc., can solve the problems of affecting the appearance of the garage and wasting paint, and achieve the effects of avoiding pollution, controlling the scope of spraying, and saving paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

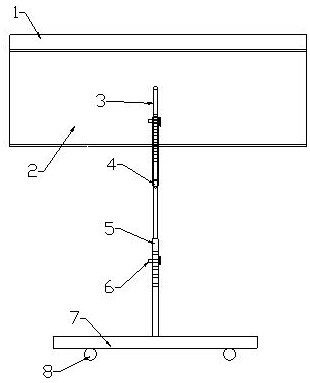

Image

Examples

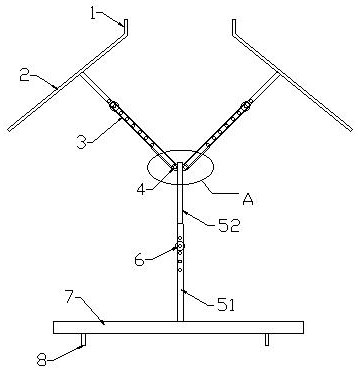

Embodiment 1

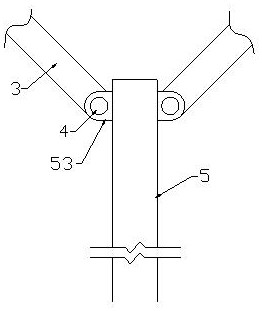

[0031] Embodiment one: if image 3 As shown, the left side and the right side of the top of the support column 5 are respectively provided with lugs 53, the lugs 53 are connected with the arm bar 3 through the locking bolt 4, between the lug 53 and the nut and / or between the lug 53 and the support arm Rubber spacers are arranged between the rods 3 . In this embodiment, the connection structure between the outrigger rod 3 and the support column 5 is easy to manufacture, so that the node position can be rotated or fixed, and the angle between the two outrigger rods 3 can be adjusted conveniently.

[0032] Further, such as Figure 4 As shown, a tension band 11 is also provided. When the locking force of the locking bolt 4 on the arm bar 3 is insufficient, the arm bar 3 may sag due to the overweight of the protective cover 2 . Tension band 11 left and right respectively are provided with one; Tension band 11 upper ends on the left side pass through from left side support arm bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com