Crop residual stem post-treatment and impurity removal process and equipment

A crop and process technology, applied in the field of post-treatment and impurity removal technology and equipment of crop residues, can solve the problems of harmful feed and affecting animal health, and achieve good effect of impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

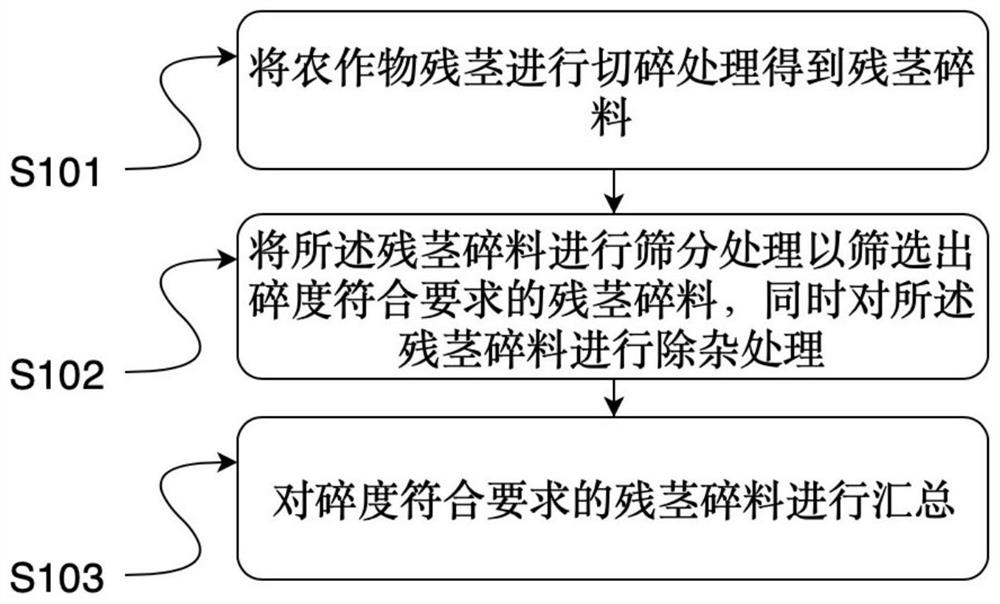

[0042] as attached figure 1 As shown, the post-treatment and impurity removal process of crop residues of the present invention includes the following steps S101-S103 (the step numbers in the following embodiments represent the implementation sequence adopted in the preferred embodiment, but each step number is not used. To limit the order of the steps, some steps may be performed synchronously or in reverse order if necessary):

[0043] Step S101, chopping the crop residues to obtain residues;

[0044] Step S102, sieving the residual stems and scraps to screen out the residual stems and scraps whose crushing degree meets the requirements, and at the same time performing impurity removal treatment on the residual stems and scraps;

[0045] Step S103, summarizing the fragments of residual stems whose crushing degree meets the requirements.

[0046] Through the above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com