Quick-preheating air sterilization equipment

A technology of air sterilization and equipment, applied in the direction of deodorization, disinfection, separation methods, etc., can solve the problems of humidity, bacteria contamination equipment, easy to grow bacteria, etc., to avoid the effect of sputtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

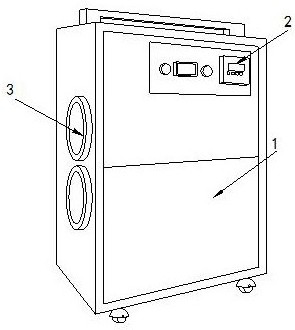

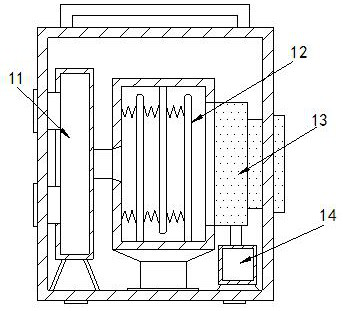

[0028] Example 1: Please refer to Figure 1-Figure 6 , the specific embodiments of the present invention are as follows:

[0029] Its structure includes a main body 1, a control panel 2, and an air inlet 3. The front end of the main body 1 is provided with a control panel 2, and two air inlets 3 are provided, and are respectively installed on the side faces of the main body 1. The main body 1 It includes a wind storage chamber 11, a sterilization block 12, a water removal device 13, and a water storage tank 14. The wind storage chamber 11 is arranged on the left side of the main body 1, and the sterilization block 12 is located in the middle of the main body 1. The water device 13 is connected to the right side of the sterilization block 12, and the water storage tank 14 is installed at the bottom of the water removal device 13.

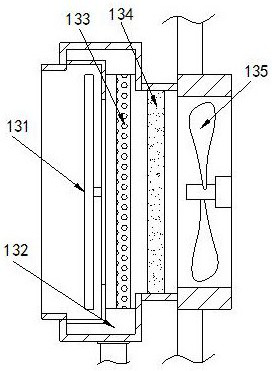

[0030] Described water removal device 13 comprises water attachment device 131, water storage tank 132, activated carbon plate 133, air purificatio...

Embodiment 2

[0035] Example 2: Please refer to Figure 7-Figure 9 , the specific embodiments of the present invention are as follows:

[0036] The water channel a4 includes an outer water rejection groove c1, a water rejection block c2, and a rubber ring c3. The bottom end of the outer rejection groove c1 is embedded with a water rejection block c2, and the inside of the water rejection block c2 is hollow, so One end of the rubber ring c3 is connected to the bottom end of the outer throwing tank c1, and the other end is connected to the side end of the water throwing block c2. The end surface of the rubber ring c3 is curved, which is beneficial to concentrate the water flow through the rubber ring c3 , to carry out the pilot flow in the water throwing block c2.

[0037] The water rejection block c2 includes a water rejection tank c21, a water drop hole c22, a water collecting ring c23, and a concentration block c24. The water removal tank c21 is arranged in the middle of the water rejecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com