Vibrating groove for screening wet mass after reconstituted tobacco moisture regaining

A reconstituted tobacco leaf and screening technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of wet lumps in reconstituted tobacco leaves, high labor intensity of operators, and low efficiency of wet lump screening, so as to avoid manual screening and improve The effect of screening efficiency and good screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solution of the present invention, the solution will be further described in detail below in conjunction with specific embodiments.

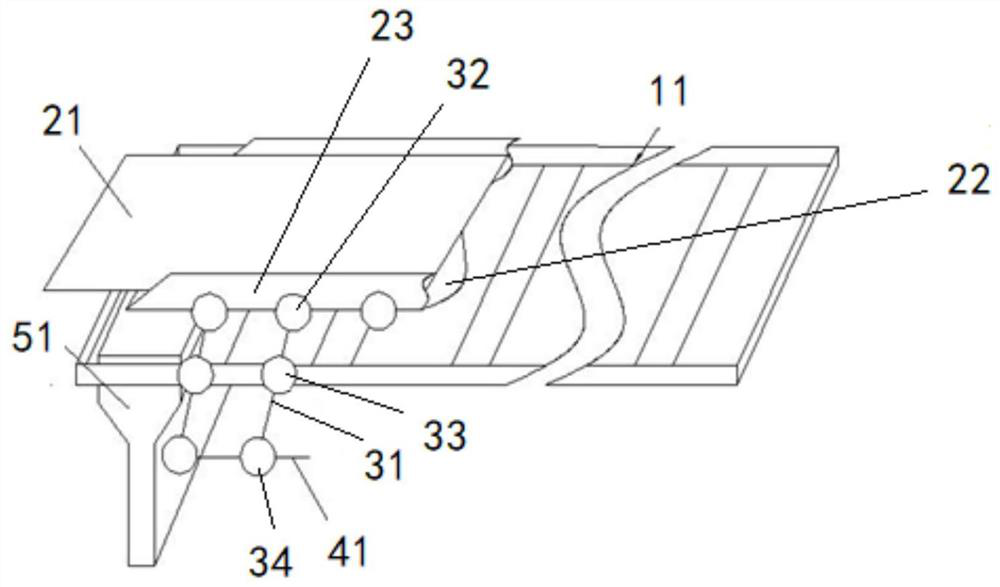

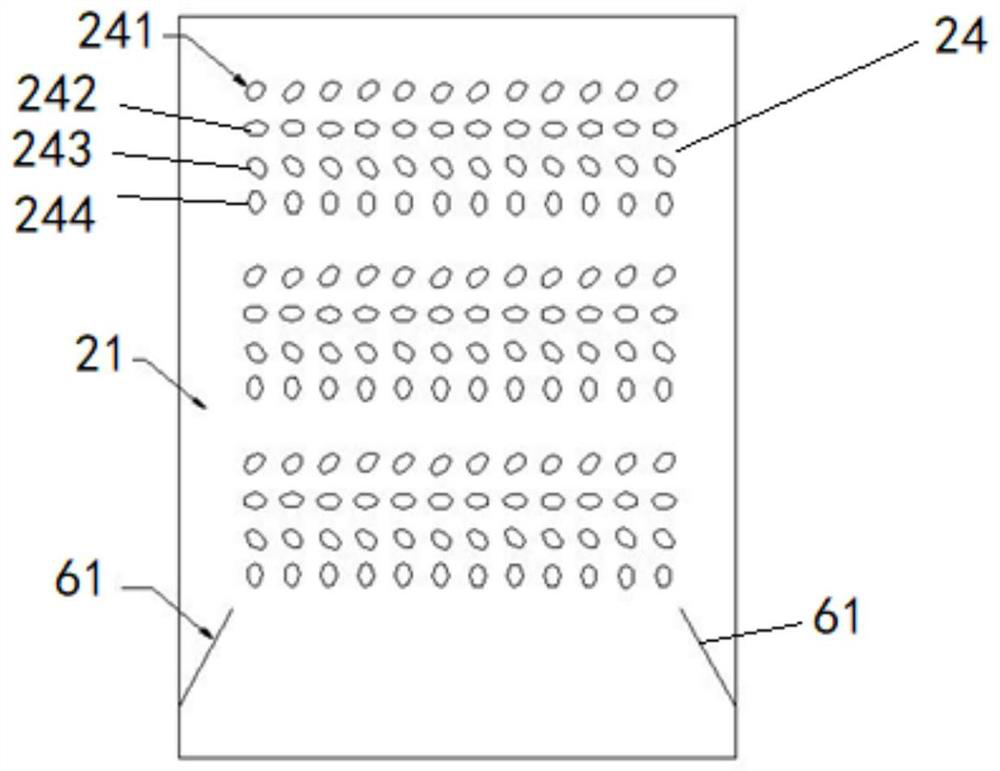

[0028] Such as figure 1 with figure 2 As shown, the embodiment of the present invention provides a vibrating tank for screening wet mass after reconstituted tobacco leaves, which includes a fixed plate 11, a double-layer screen, a rocker arm 31, a fixed rod 41, and a collection device 51. The double-layer screen The net is arranged at the outlet of the dampening drum, the upper end 32 of the rocker arm is connected to the side plate 23 of the double-layer screen, and the middle position 33 of the rocker arm is connected to the side wall of the fixed plate 11; The fixed rod 41 is arranged horizontally, and one end of the fixed rod 41 is connected with the lower end 34 of the rocker arm, and the other end of the fixed rod 41 is connected with the telescopic dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com