Battery piece with non-uniformly distributed grid lines

A technology of uniform distribution and battery slices, which is applied to circuits, electrical components, semiconductor devices, etc., can solve the problems of crystalline silicon and battery process difficulty, uneven electrical performance of battery process, and increase the manufacturing cost of battery slices, etc., to achieve relief adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

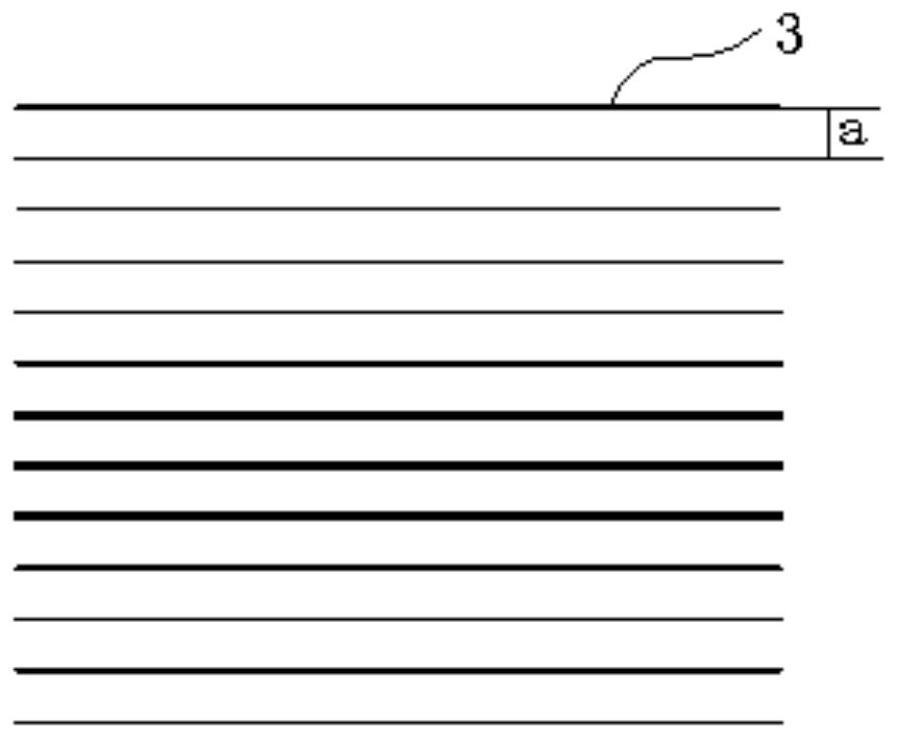

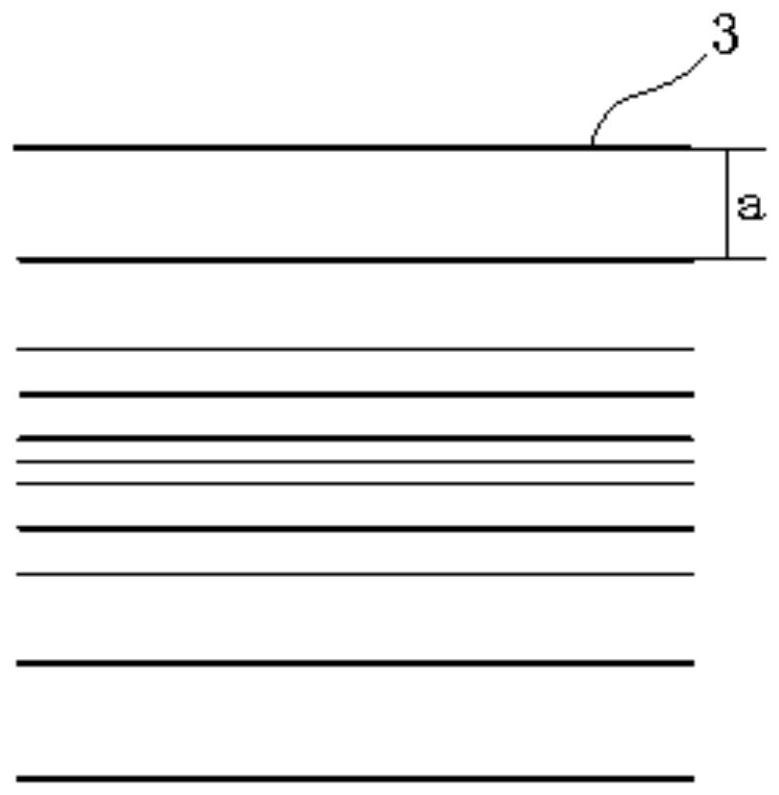

[0052] Such as Figure 1-Figure 2 As shown, the sub-grid lines 3 of the battery sheet in which the grid lines are unevenly distributed in this embodiment are arranged in multiple rows, the sub-grid line spacing a of the multiple sub-grid lines 3 is equal, and the sub-grid width of the sub-grid lines 3 has multiple A size specification. Specifically, as figure 1 As shown, the sub-gate line 3 located in the middle has a smaller sub-gate width, while the sub-gate lines located on both sides have a larger width. Such as figure 2 As shown, the sub-gate line 3 located in the middle has a larger sub-gate width, while the sub-gate lines located on both sides have a smaller width.

Embodiment 2

[0054] Such as Figure 3-Figure 4 As shown, in this embodiment, the sub-grid lines 3 of the battery sheet with unevenly distributed grid lines are arranged in multiple rows, the sub-grid widths of the multiple sub-grid lines 3 are equal, and the sub-grid line spacing a of the sub-grid lines 3 has multiple rows. A size specification. Specifically, as image 3 As shown, the sub-grid spacing a of the sub-grid lines 3 located in the middle is relatively small, while the sub-grid spacing a of the sub-grid lines on both sides is relatively large, and the sub-grid spacing a gradually increases from the middle to both sides. Such as Figure 4 As shown, the sub-grid line spacing a of the sub-grid lines 3 located in the middle is larger, while the sub-grid line spacing a of the sub-grid lines located on both sides is smaller, and the sub-grid line spacing a gradually decreases from the middle to both sides.

Embodiment 3

[0056] Such as Figure 5-Figure 6 As shown, the sub-grid lines 3 of the battery sheet in which the grid lines are not uniformly distributed in this embodiment are arranged in multiple rows and columns, the sub-grid width and the sub-grid line spacing a of the multiple sub-grid lines 3 are equal, and the sub-grid lines 3 The sub-grid pitch b has various sizes and specifications. The auxiliary grid lines 3 arranged vertically are continuous lines. Specifically, as Figure 5 As shown, the vertical sub-grid lines 3 are located on both sides of the lateral sub-grid lines 3 . Such as Figure 6 As shown, the vertical sub-grid lines 3 are located in the middle of the lateral sub-grid lines 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com