Equipment residual life evaluation method based on continuous Weiner process damage

A technology for life evaluation and equipment, applied in computer-aided design, design optimization/simulation, biological neural network model, etc., can solve the problems of large error and damage in remaining life evaluation, and achieve the effect of accurate evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

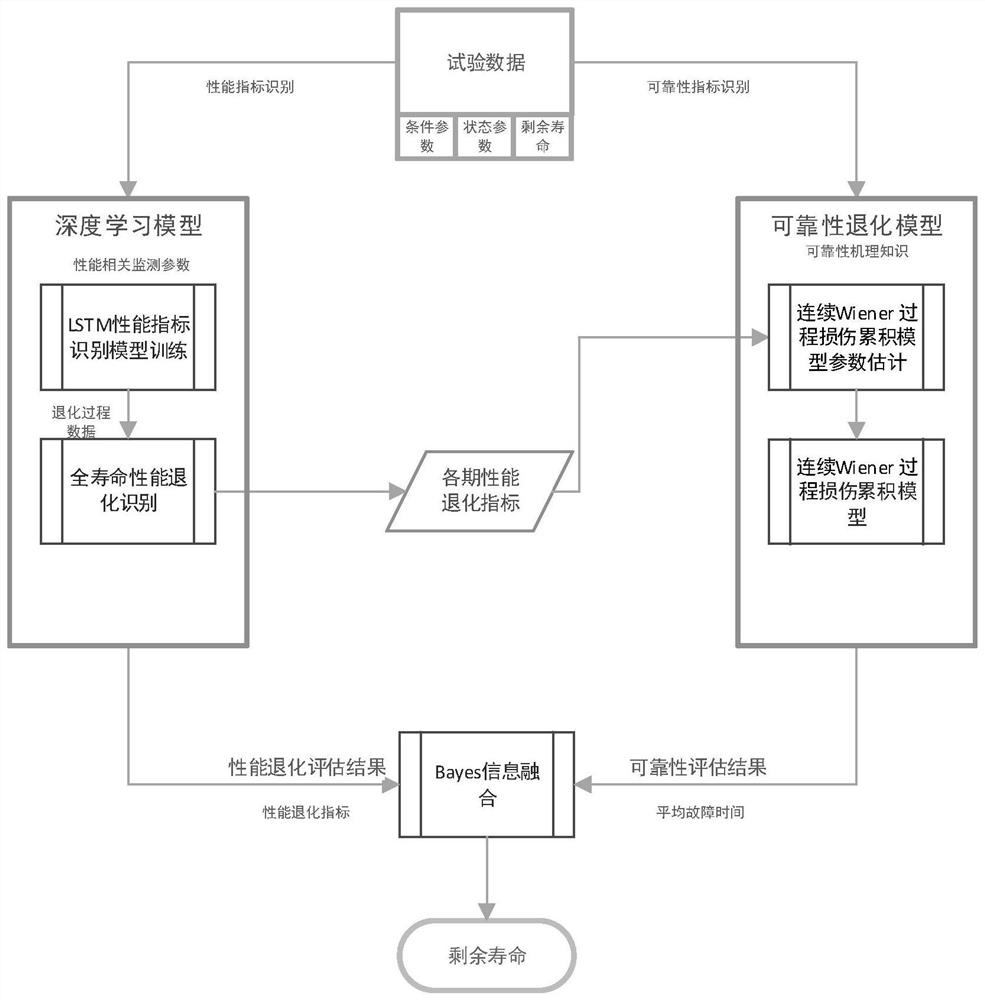

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

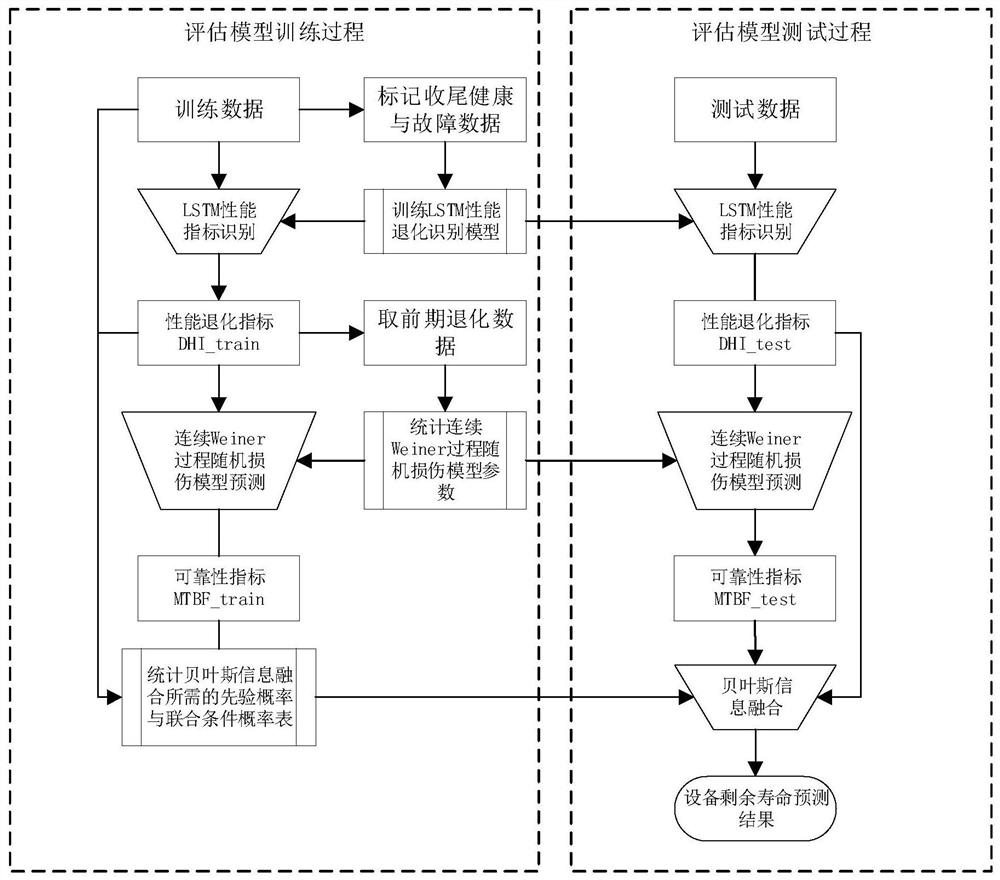

[0054] Embodiment 1: a kind of equipment remaining life assessment method based on continuous Weiner process damage, the method comprises the following steps:

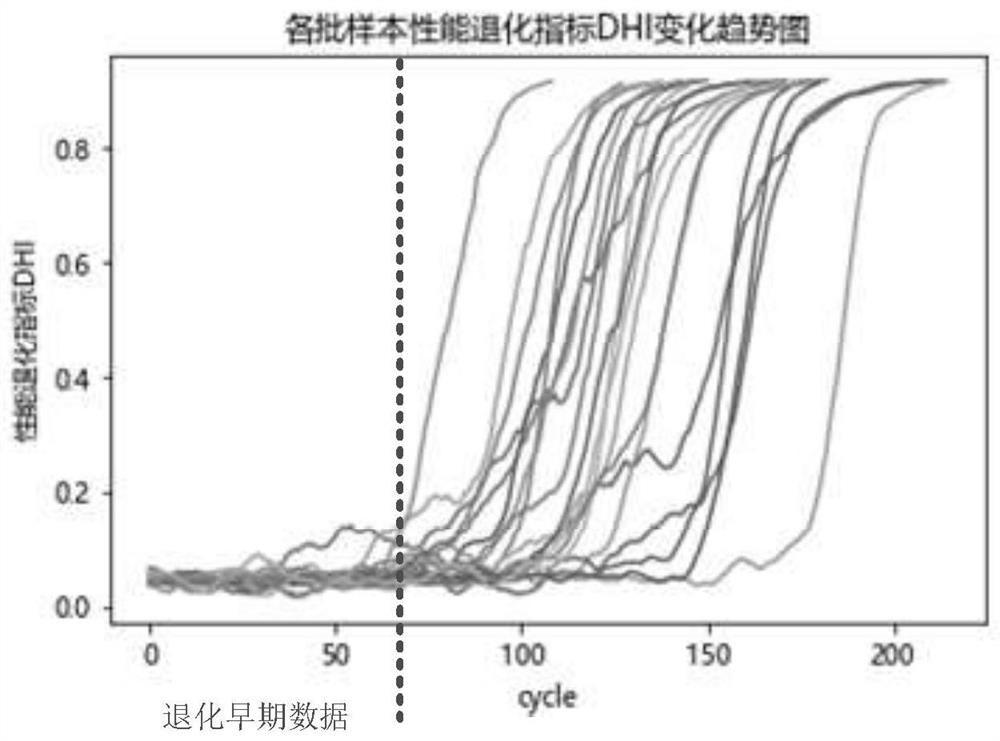

[0055] Step 1: Initialize the monitoring data of the whole life cycle of n sample devices, and divide the data into multiple monitoring batches through sliding windows. Take the first two batches of data of each device, and mark the random number whose performance degradation is 0.01~0.05, take the last batch of data of each device, mark the random number whose performance degradation is 0.9~0.91, and mark the second last batch of data, Mark the random number whose performance degradation is between 0.89 and 0.9;

[0056] Step 2: Establish a general long-term short-term memory network (LSTM), and input the final batch monitoring data of each device and the corresponding performance degradation label value into the long-term short-term memory network (LSTM) for training;

[0057] Step 3: Input the trained long-short-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com