Test and calculation method for measuring equivalent plastic strain forming limit diagram

A technology of equivalent plastic strain and forming limit diagram, applied in the direction of applying stable tension/pressure to test material strength, measuring device, strength characteristics, etc., can solve the problem of not covering the strain path in the shear area, EPS-FLD cannot be input, Impact and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] In this embodiment, the test and calculation method for determining the equivalent plastic strain forming limit diagram of the present invention is described in detail with the material DP780 / 1.4mm, including the following steps:

[0103] Step 1. According to the test method specified in the material hole expansion test standard ISO / TS 16630 or GB / T 24524-2009, the hole expansion rate λ=23% of the material DP780 is measured;

[0104] Step 2. Calculate the true fracture strain with edge damage The true fracture strain with edge damage is Calculate according to the formula:

[0105]

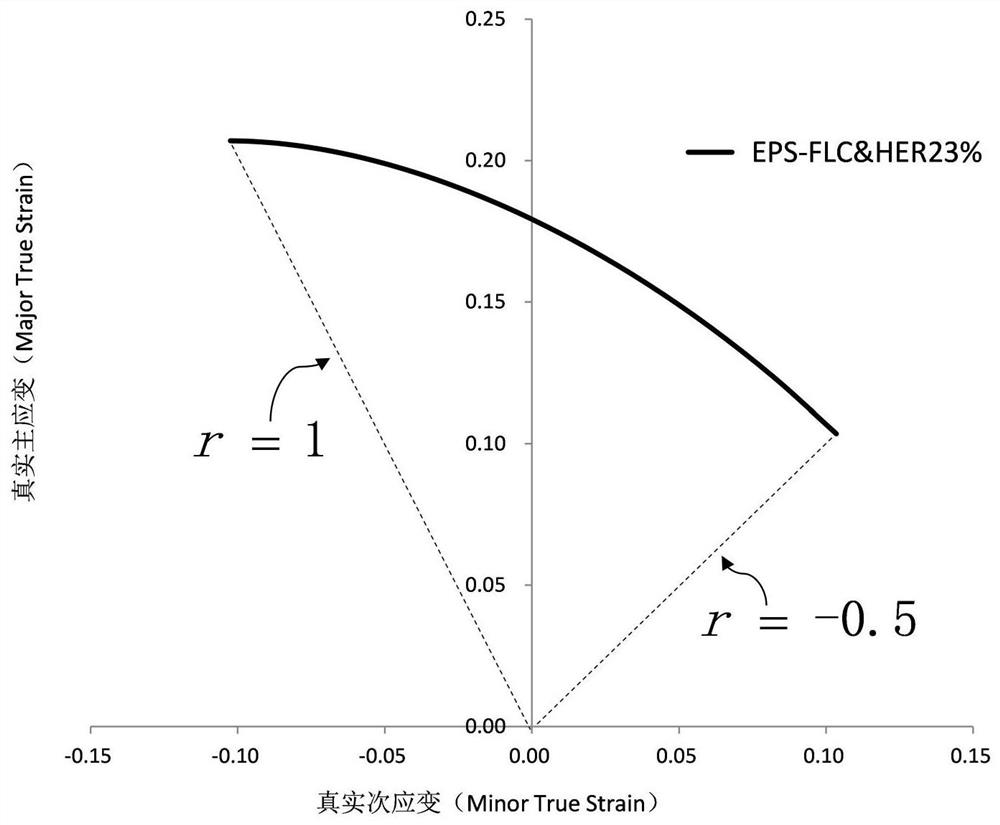

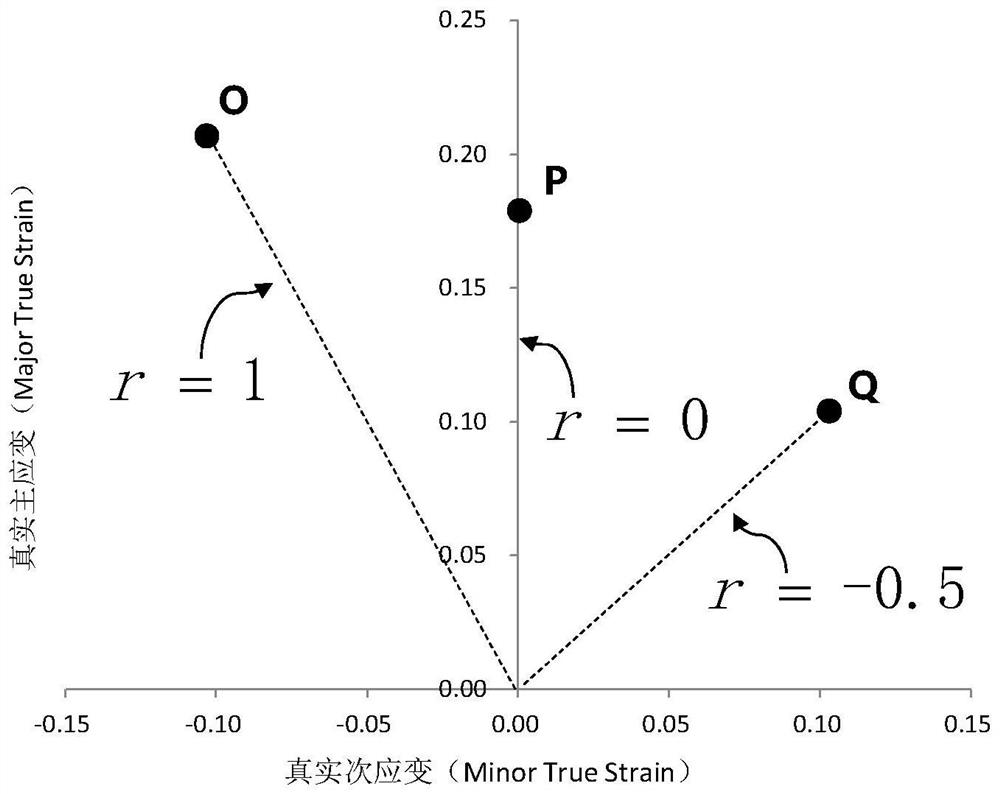

[0106] Step 3. Calculate the real principal strain ε under different simple strain paths according to the following two formulas: major and true secondary strain ε min or :

[0107]

[0108]

[0109] Among them, r is the plastic strain ratio, which is used to characterize the simple strain path, and its value range is [-0.5,1], then the corresponding ε min or The value range ...

Embodiment 2

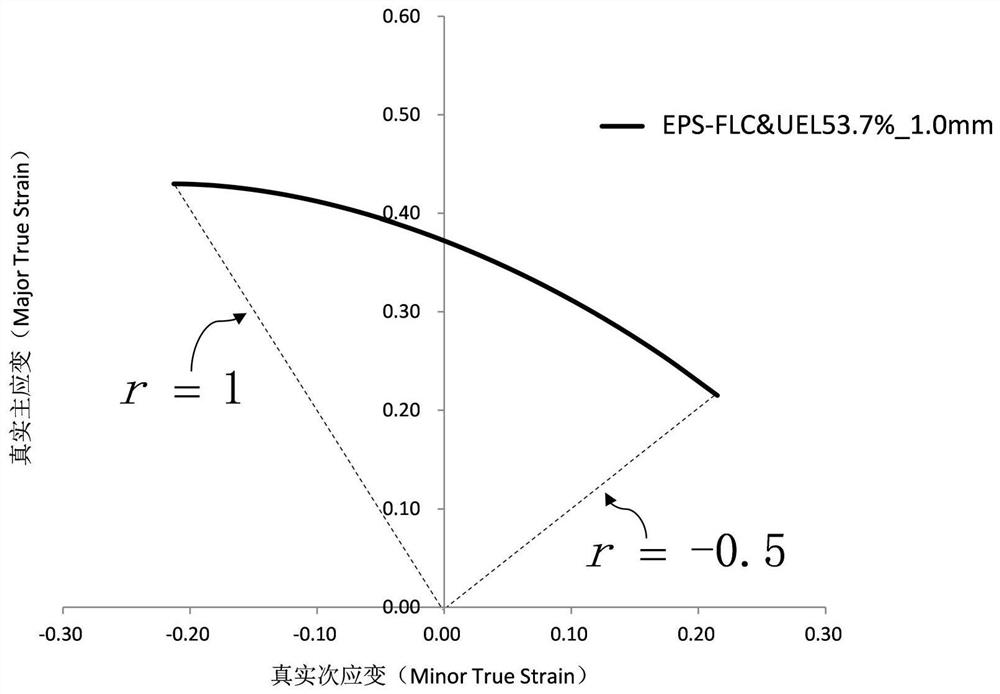

[0126] In this embodiment, the test and calculation method for determining the equivalent plastic strain forming limit diagram of the present invention is described in detail with the material DP780 / 1.4mm, including the following steps:

[0127] Step 1. Determine the uniform elongation of the material The uniform elongation It means: in the uniaxial tensile test, in the fracture center area of the sample, the length, width and height taken are l 10 ·w 10 The maximum engineering strain of a 1.4mm finite body A that is always under uniform necking deformation is calculated by the following formula:

[0128]

[0129] Among them, the initial gauge length l 10 =10mm, initial width w r =10mm, the subscript r=10 indicates the size of the initial gauge length and initial width, l UEL It means that the measured deformation length of finite body A at the end of uniform necking is 12.71 mm.

[0130] Step 2. Calculate the true uniform strain The true uniform strain Calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com