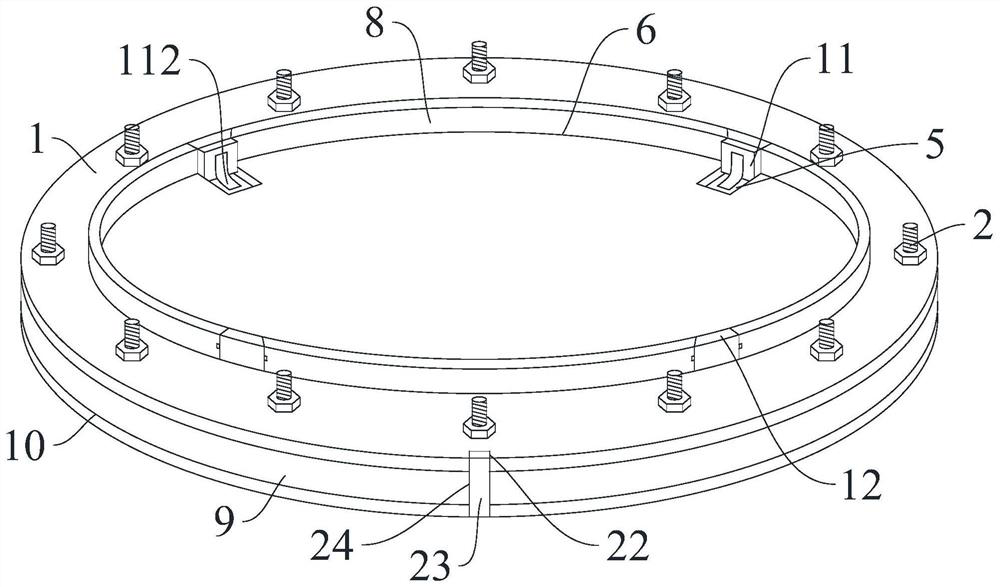

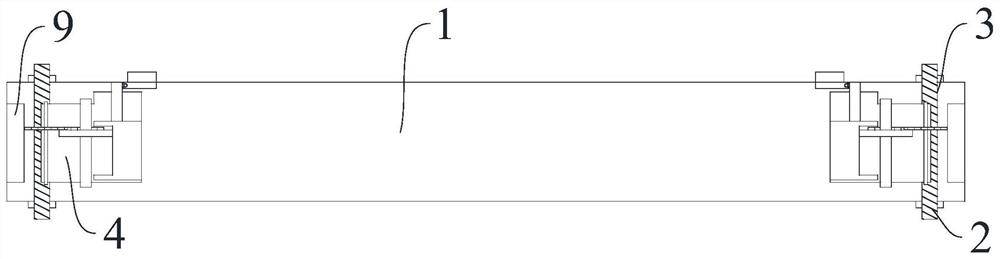

Stainless steel flange with external adjusting module

An adjustment module, stainless steel technology, applied in the direction of flange connections, pipes/pipe joints/fittings, passing components, etc., can solve the problems of inability to adjust, limited sealing effect, etc., to improve safety, improve sealing performance, and avoid misoperation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

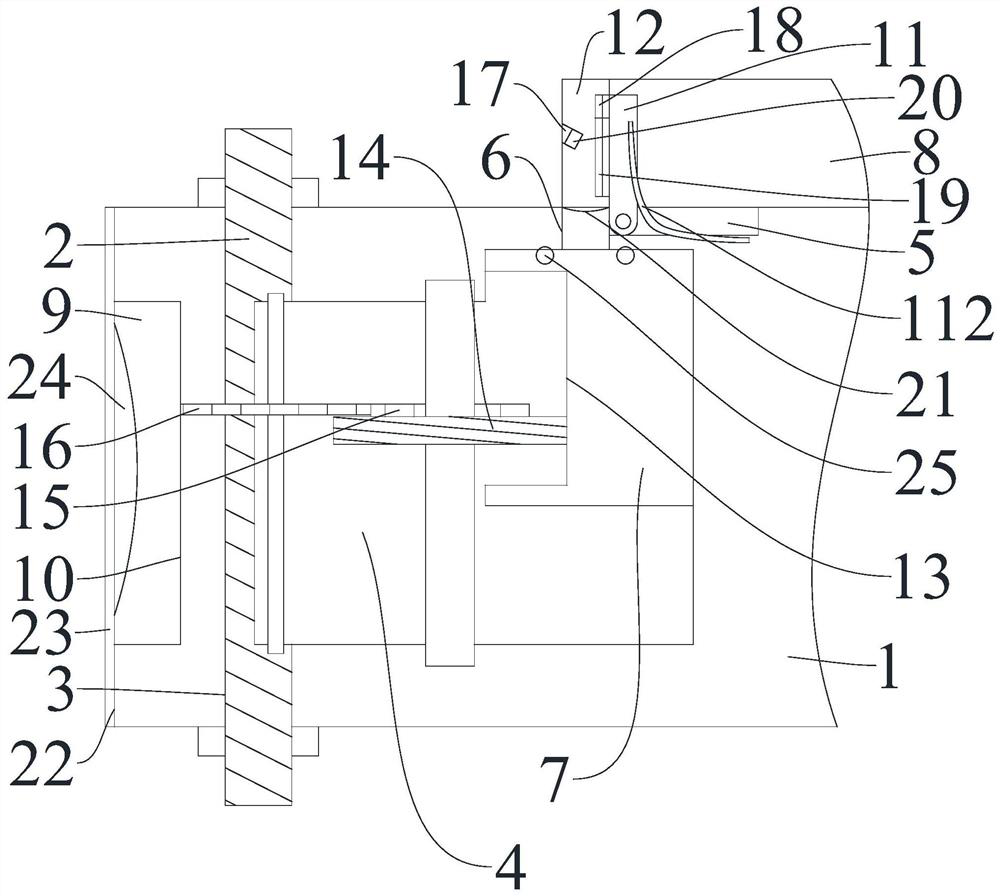

[0024] Embodiment: Press the elastic limiting plate 23 from the outside and press it into the arc-shaped deformation groove 24, so that both sides of the elastic limiting plate 23 are tilted and separated from the lateral limiting card slot 22, and then the lateral adjustment ring 9 is rotated, Control the rotation of the internal adjustment mechanism to drive the ring-shaped lifting frame 7 to rise, then turn the inner flip block 11 outward, insert the outer sealing plate 12 into the longitudinal slope on one side of the arc-shaped sealing plate 8, and connect the arc-shaped sealing plate 8 and the outer sealing plate 12 Form a cylindrical mechanism.

[0025] Further, in order to cooperate with the flip adjustment, the inner surface of the strip-shaped flip storage tank 5 is symmetrically provided with lateral assembly blind holes, and the elastic sealing module includes an inner flip block 11 installed inside the strip-shaped flip storage tank 5, fixed on the strip-shaped fli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com