Method for reducing bending failure of tubular piles in soft soil

A technology of bending failure and pipe piles, applied in soil protection, sheet pile walls, buildings, etc., can solve the problems of poor lateral bearing capacity of a single pipe pile, weak bearing pressure of pipe piles, and weak lateral stiffness, etc., to achieve Improve bearing capacity, improve efficiency, and reduce the effect of bending damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

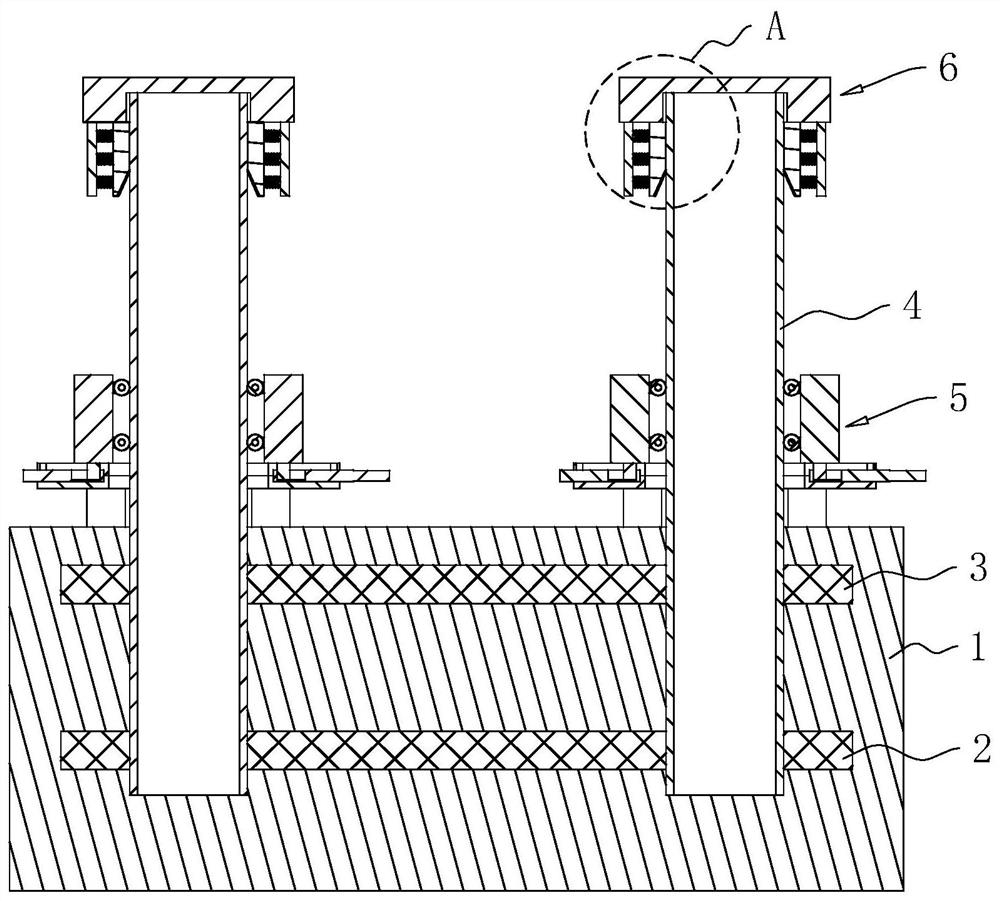

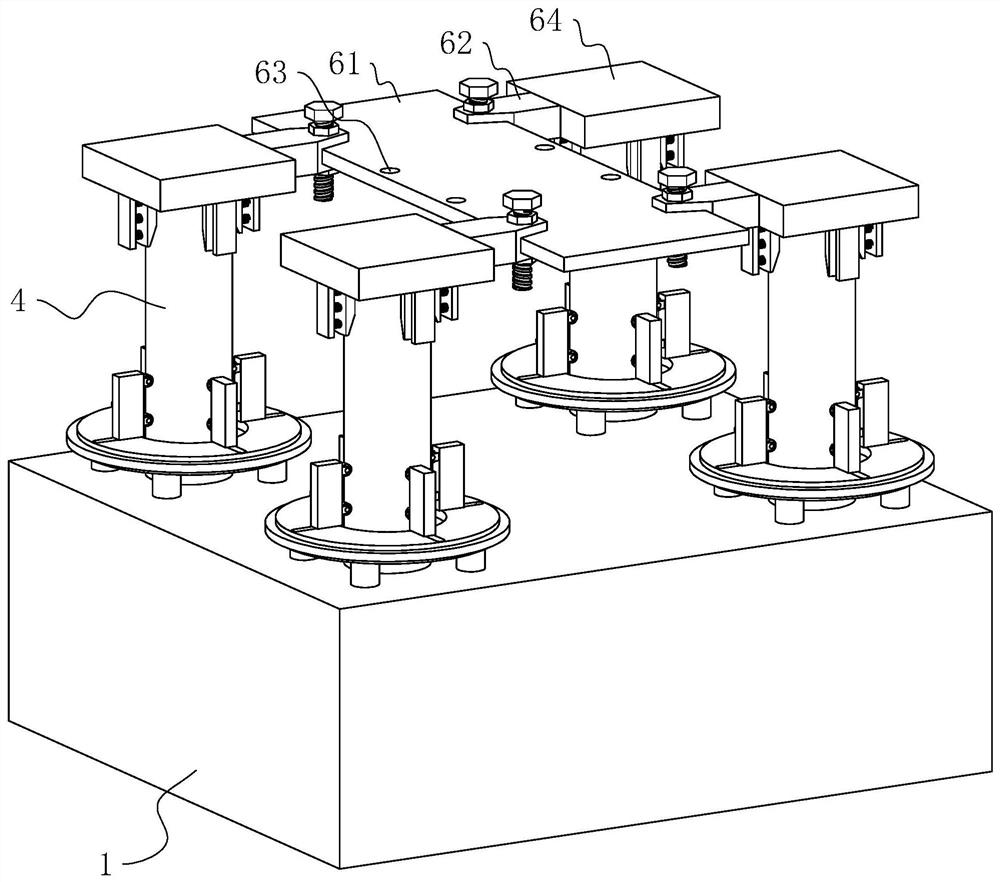

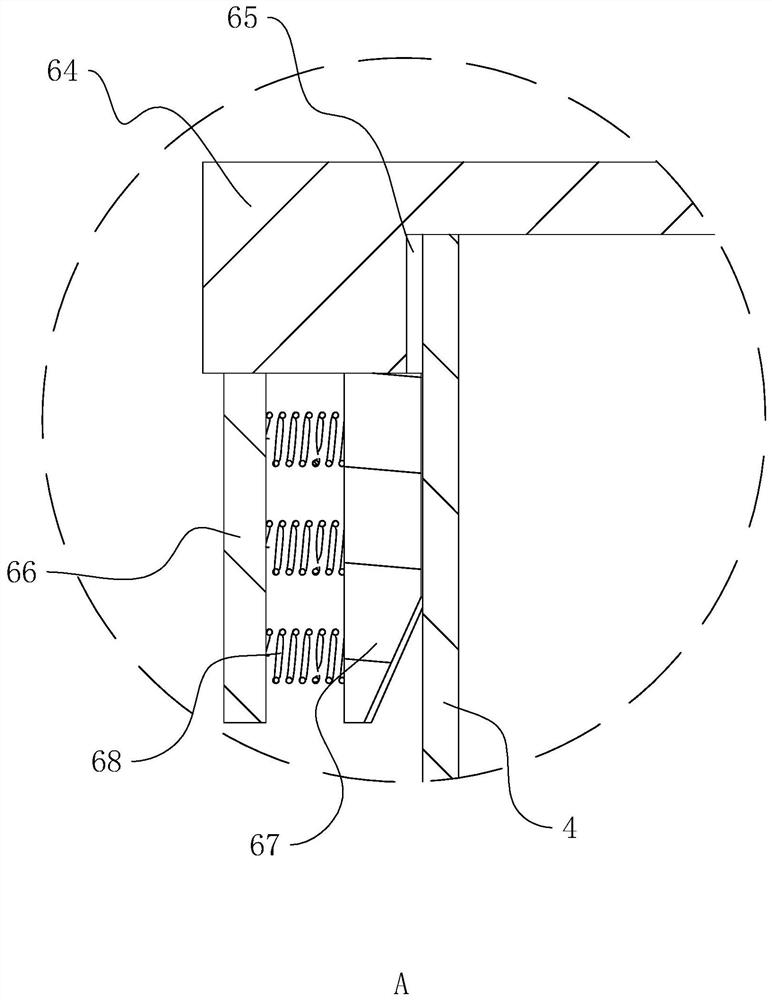

[0042] The following is attached Figure 1-4 The application is described in further detail.

[0043] The embodiment of the present application discloses a method for reducing bending damage of pipe piles in soft soil. refer to figure 1 , the method of reducing the bending damage of pipe piles in soft soil includes the following steps:

[0044] Step1: Survey and testing of the soil layer 1 of the construction site. The survey and testing can be carried out by drilling.

[0045] Step2: Set the first reinforcement layer 2 at the position of the design elevation.

[0046] Step3: Set the second reinforcement layer 3 at the design elevation, and the second reinforcement layer is located above the first reinforcement layer.

[0047] The materials used for the first reinforcement layer 2 and the second reinforcement layer 3 are all concrete, and the first reinforcement layer 2 and the second reinforcement layer 3 are laid by high-pressure rotary spraying method at the same time. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com