Novel sewing machine

A sewing machine and a new type of technology, applied in sewing machine components, sewing machine control devices, sewing equipment, etc., can solve the problems of affecting the sewing effect of the sewing machine, inconvenient maintenance and maintenance, unable to ensure synchronization, etc. Simple structure and the effect of reducing the probability of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

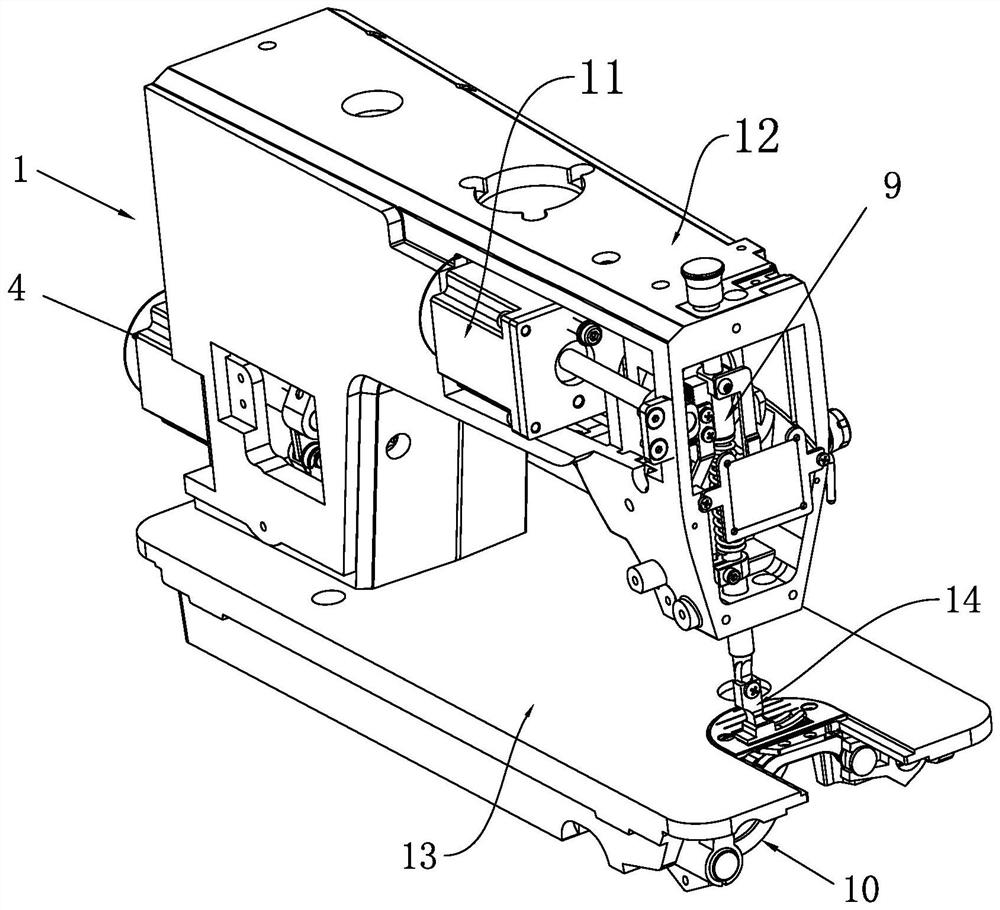

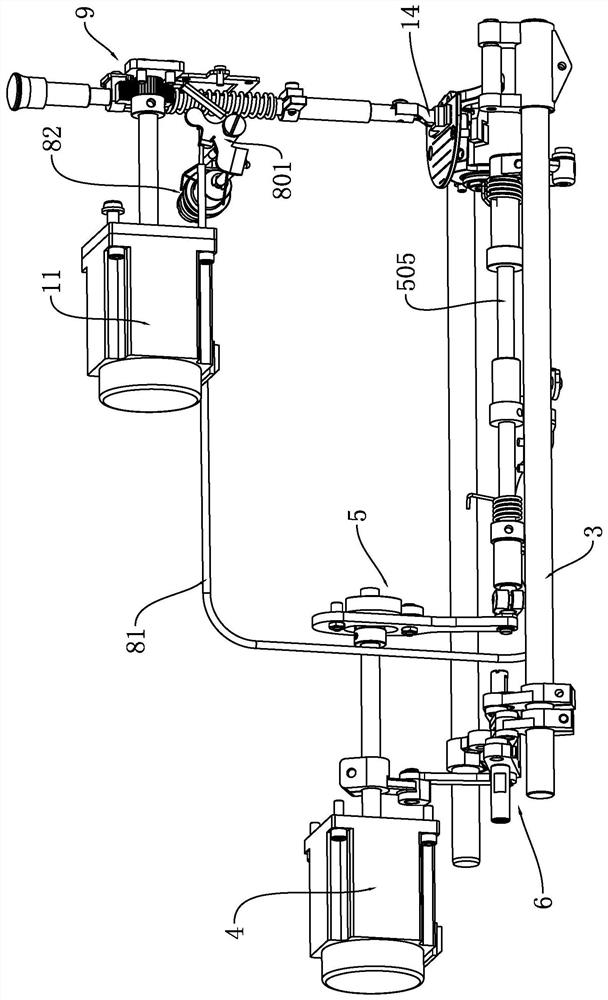

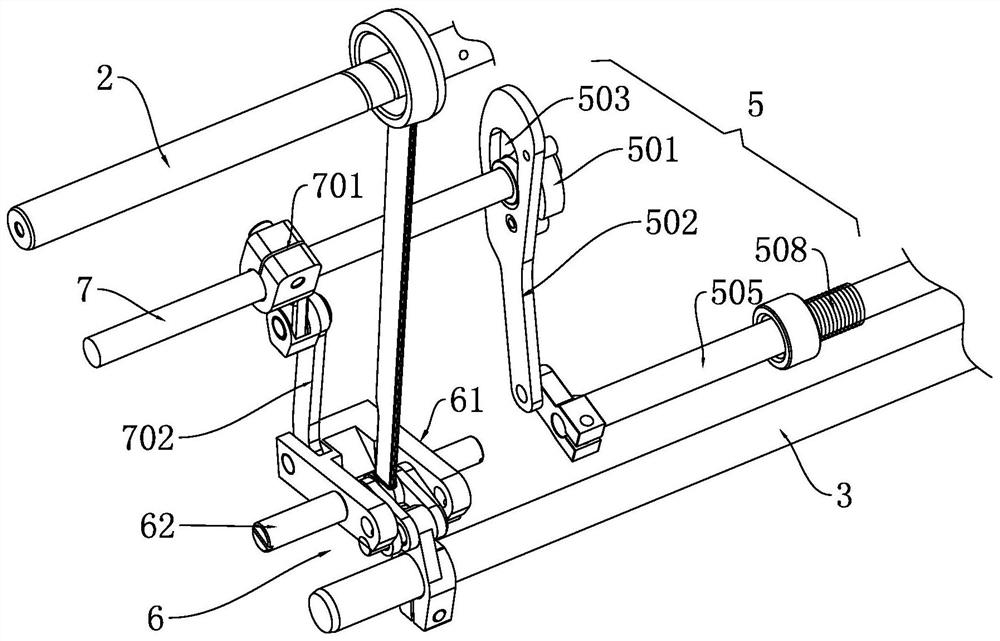

[0080] Such as Figure 1-Figure 12 As shown, a new type of sewing machine includes a frame 1, a main shaft 2, a feeding shaft 3, a first drive motor 4, a thread trimming mechanism 5 and a reverse sewing adjustment mechanism 6, and the reverse sewing adjustment mechanism 6 is arranged on the main shaft 2 Between the feeding shaft 3, the feed swing seat 61 in the reverse stitching adjustment mechanism 6 rotates around the set pin shaft 62, and the angle at which the feed swing seat 61 rotates around the pin shaft 62 determines the needle pitch and The switching of reverse sewing is the rotation speed and direction of rotation of the feeding shaft 3;

[0081] The thread loosening mechanism 8 is connected to the thread cutting shaft 505 through the cable assembly 81, and the rotation of the thread cutting shaft 505 drives the thread loosening mechanism 8 to loosen the thread;

[0082] The thread trimming mechanism 5, the reverse stitching adjustment mechanism 6 and the thread loo...

Embodiment 2

[0119] This embodiment is basically the same as Embodiment 1, the difference is that: in combination Figure 13-14 As shown, the thread trimming mechanism 5 includes: a thread trimming crank 504, which is installed on the output shaft of the first drive motor 4 and rotates therewith; the working end of the thread trimming crank 504 is provided with a push shaft 510;

[0120] The third connecting rod 502 has a guide groove 503; the output shaft passes through the guide groove 503 and limits the third connecting rod 502;

[0121] One side of the third connecting rod 502 is provided with a hook portion 509 , the push shaft 510 snaps into the hook portion 509 and drives the third connecting rod 502 to move up and down along the effective stroke of the guide groove 503 .

[0122] Preferably, when the output shaft reversely rotates and resets, when the reset torsion spring 508 of the thread trimming mechanism 5 fails, the push shaft 510 forcibly resets the thread trimming mechanism ...

Embodiment 3

[0124] This embodiment is basically the same as Embodiment 1, the difference is: as Figure 15 As shown, an eccentric wheel 99 is installed on the output shaft of the second driving motor, and a groove rail 907 is arranged on one side of the driving sleeve 90 , and the eccentric wheel 99 is placed in the groove rail 907 . The output shaft of the second driving motor drives the eccentric wheel 99 to rotate in the groove rail 907 and then drives the movement of the presser foot rod 903 . And compared with the structures such as the driving track provided in the prior art, the processing of the present invention is more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com