Cable collecting frame used in field of housing construction engineering

A technology for housing construction projects and collection racks, applied in the field of cable collection racks, can solve the problems of different lengths of cables, difficulty in collection, and difficulty in temporarily accessing cables, etc., and achieve the effect of reducing labor force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

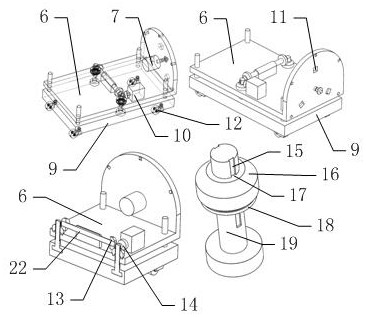

[0045] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples or drawings are used to illustrate the present invention, but not to limit the scope of the present invention.

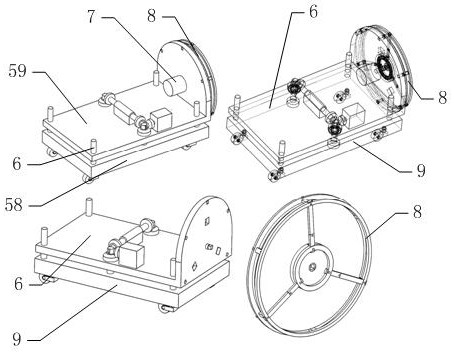

[0046] Such as figure 2 Shown, it comprises traveling mechanism 58, elevating mechanism 59, collection frame 8, and wherein elevating mechanism 59 is installed on the upper side of running mechanism 58, and collecting frame 8 is removably installed on an end of elevating mechanism 59.

[0047] Such as image 3 Shown, above-mentioned walking mechanism 58 is made up of walking platform 9 and four universal wheels 12 installed on the four corners of walking platform 9 lower sides. The convenience of using the collection frame 8 is improved by the designed traveling mechanism 58 .

[0048] Such as image 3 As shown, above-mentioned lifting mechanism 59 comprises guide bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com