Vibration balance type low-noise deep sea hydrophone and manufacturing method thereof

A vibration balance and manufacturing method technology, applied to transducers, instruments, sensors and other directions used underwater, can solve the problems of poor anti-shock noise performance, low hydrostatic pressure resistance, etc., to achieve low cost, guaranteed effectiveness, production simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to illustrate the technical features of the solution more clearly, the solution will be described below through specific implementation modes.

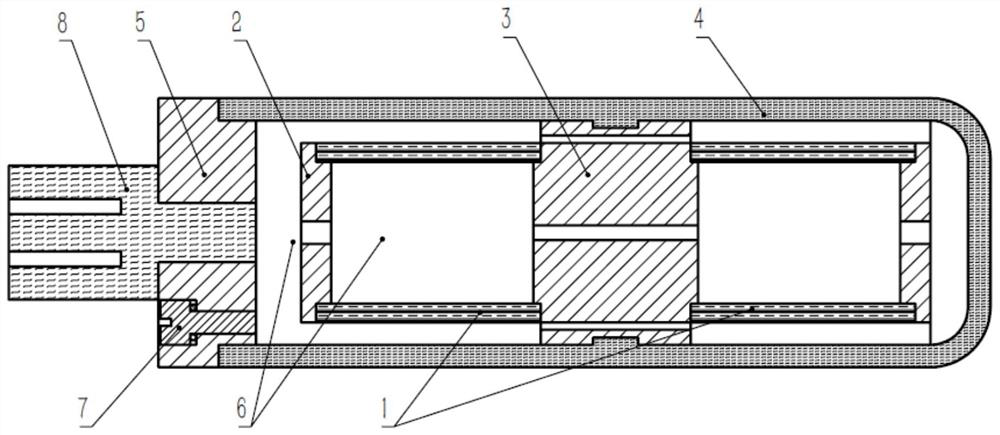

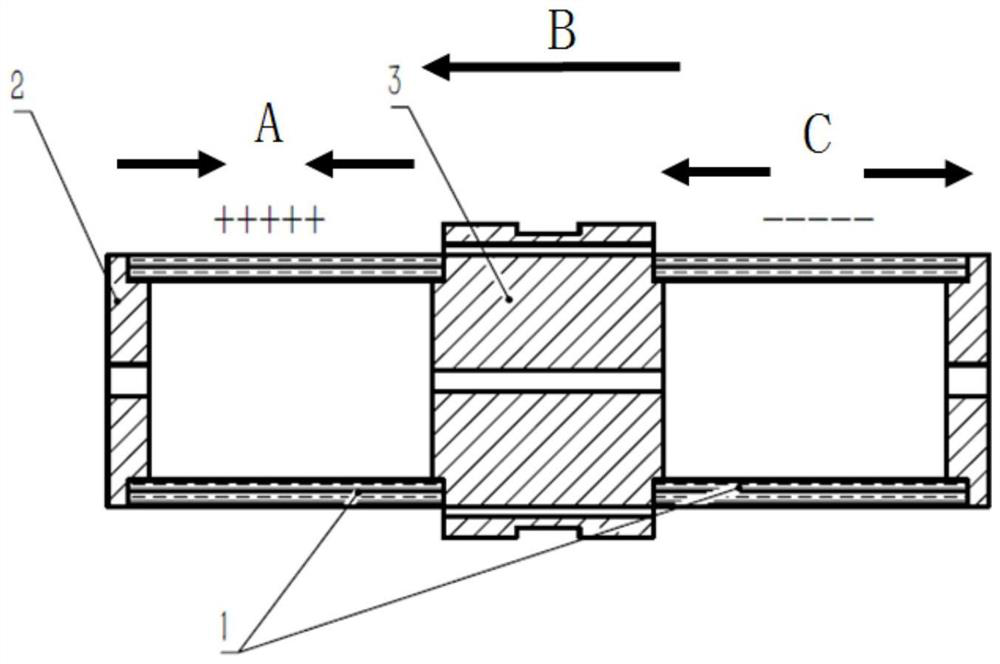

[0039] see figure 1 , the present invention uses two piezoelectric ceramic tubes with dimensions of Φ25×Φ19×30 to be connected in parallel. The size and quantity determine the final performance of the hydrophone. Under the condition, the oily medium (generally using silicon oil) can freely enter and exit the inner and outer cavity of the piezoelectric ceramic tube 1 to achieve pressure balance; the metal block 3 in the middle is made of brass or stainless steel, and the two piezoelectric ceramic tubes installed symmetrically at both ends Tube 1 together constitutes the key structure of the hydrophone. Among them, the sound-transmitting oil bladder requires both watertight and sound-transmitting functions, and requires excellent oil resistance. , oil resistance, sound permeability are excellent;

[0040] Such as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com