Binary optical lens with high dispersion and high refractive index

A high refractive index, binary optics technology, applied in optics, optical components, chemical instruments and methods, etc., can solve the problems of affecting light refraction, single applicable scene, easy to scratch the mirror surface, etc., to achieve increased light transmittance, The effect of increasing fitness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

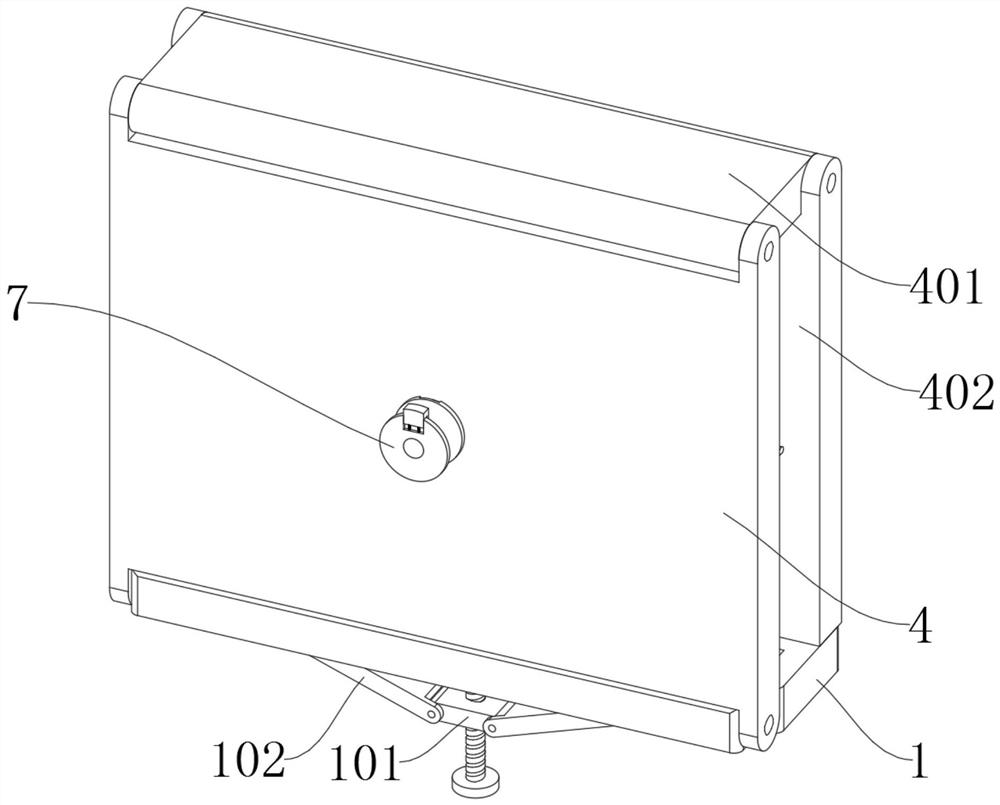

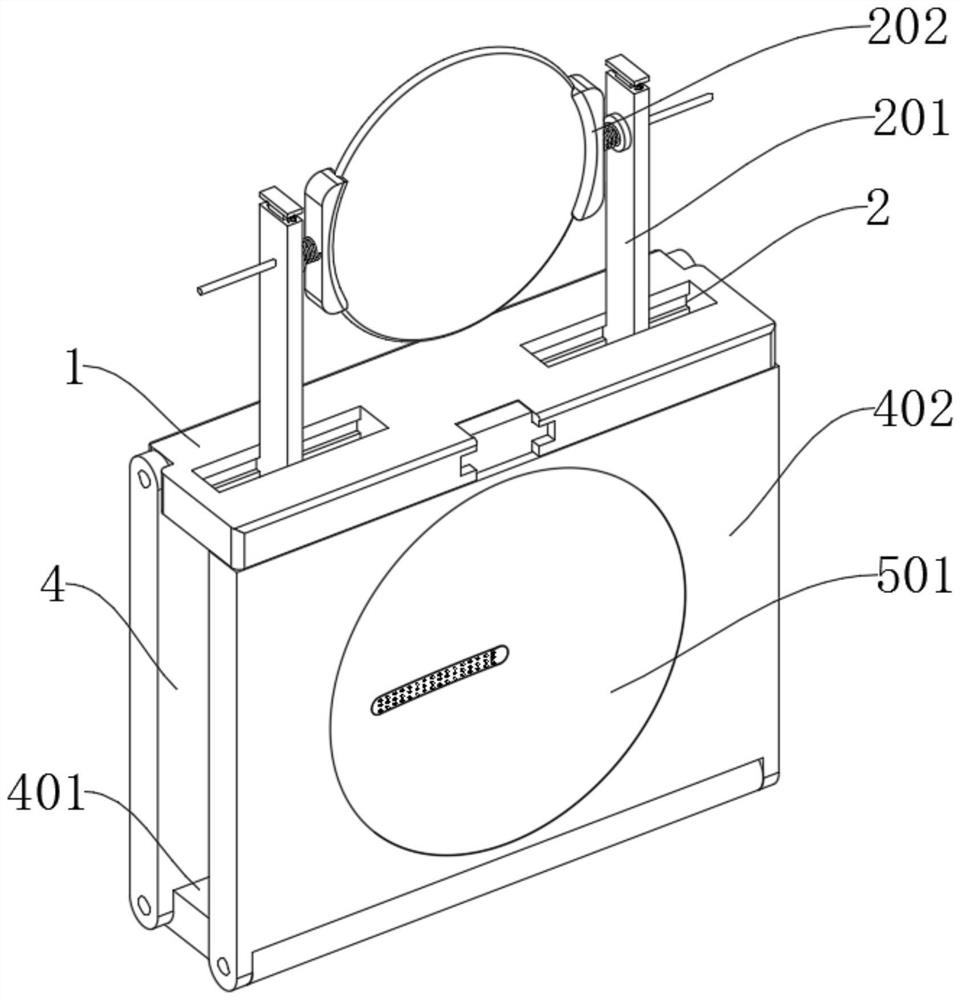

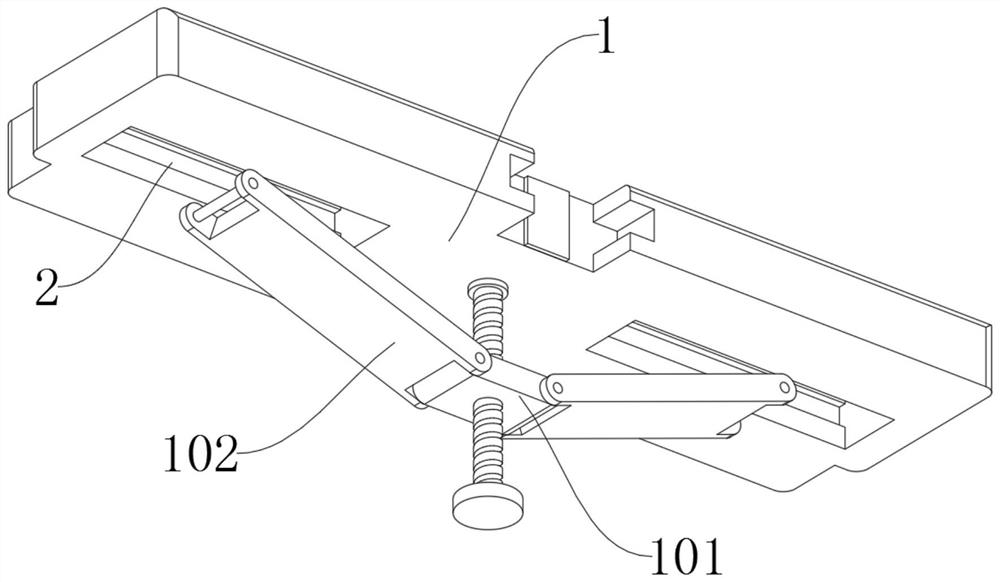

[0034] as attached figure 1 To attach Figure 8 Shown:

[0035] The present invention provides a binary optical lens with high dispersion and high refractive index, which includes a main body 1, a chute 2, a vertical groove 3, a carrier plate 4, an inner groove 5, a slot 6 and a fixing plate 7, the main body 1 is a rectangular plate structure, And the side of the main body 1 is provided with a card slot; the chute 2 is a cross-shaped structure, and the chute 2 is arranged on the top of the main body 1, and the slide plate 201 inside the chute 2 is connected with the support plate 102 through the rotating shaft; the carrier plate 4 passes through The rotating shaft is installed on the side of the main body 1, and the buckle of the side end of the outer panel 402 of the carrier board 4 is installed in the slot on the side of the main body 1; the inner groove 5 is a circular structure, and the inner groove 5 is respectively arranged on the carrier board 4 and the panel 402 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com