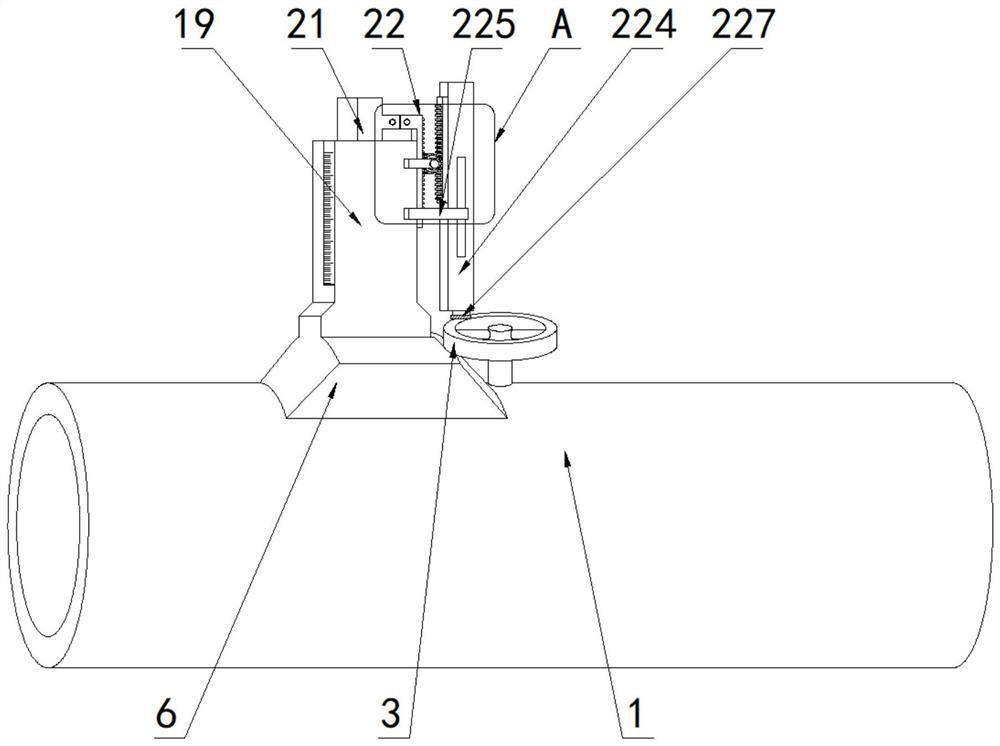

Pipeline valve detection equipment and detection method thereof

A technology for testing equipment and pipeline valves, applied in mechanical equipment, valve devices, engine components, etc., can solve problems such as low safety, inability to play an early warning role, and achieve good results, intuitive and convenient detection, and good use effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

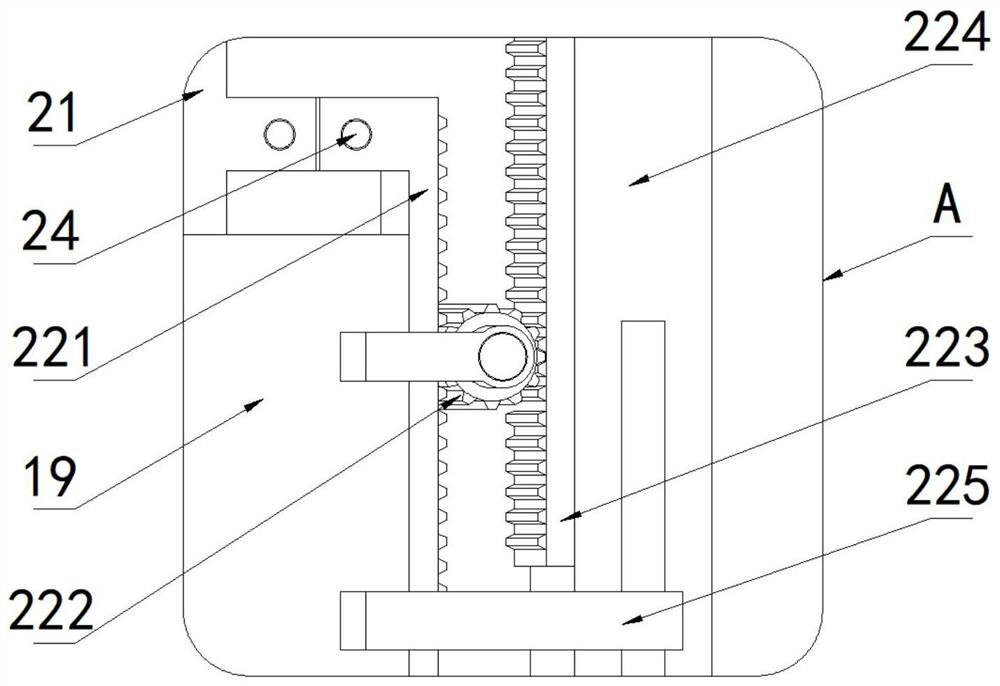

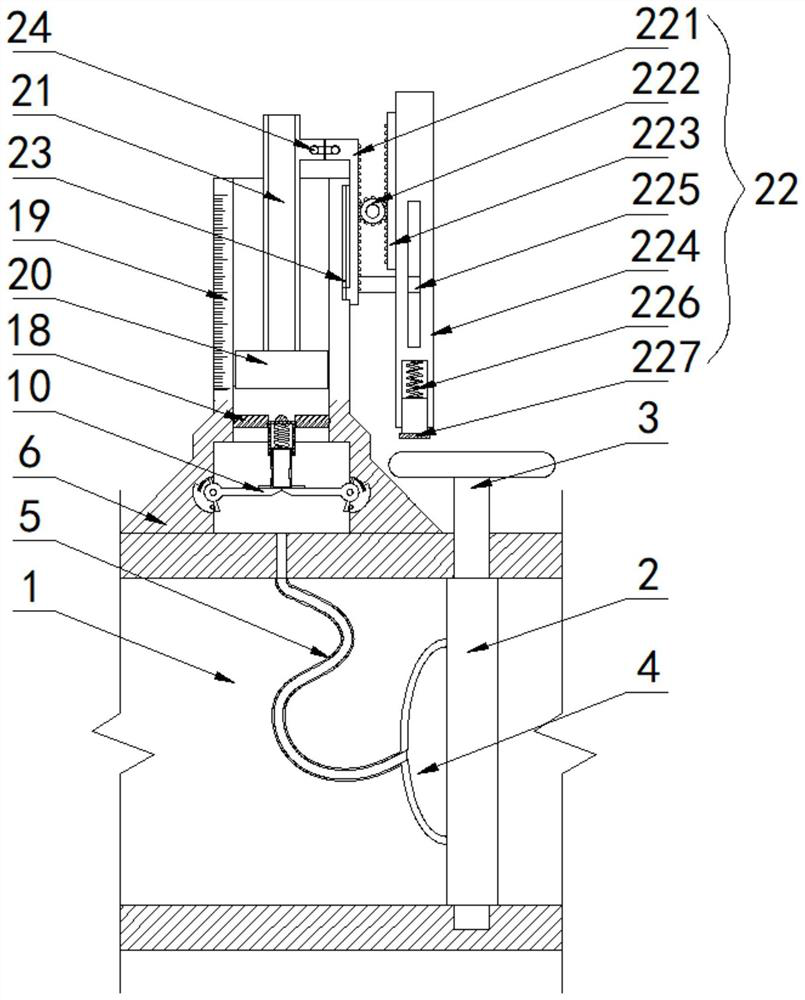

[0040] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0041]Some existing valve detection equipment usually only detects the tightness of the valve when testing the valve, and cannot detect the valve plate inside the pipeline, which may easily cause the valve plate to be subjected to excessive pressure and cause damage to the valve plate or water leakage. The hammer effect causes the overall damage and rupture of the pipeline, which poses a serious safety hazard. Moreover, the existing detection equipment is used in a single way. It only places the pressure inside the water pipe to detect the water pressure, and cannot directly detect the pressure received by the valve plate. And observation, and the use of detection tools is relatively simple, it is easy to cause the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com