Ventilating device with oil preventing function

A ventilation device and function technology, which is applied in the field of the reducer of the helicopter transmission system, can solve the problems of increasing the liquid-gas ratio of the ventilation plug, the oil mist of the reducer, and reducing the oil-gas separation efficiency of the ventilation plug, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

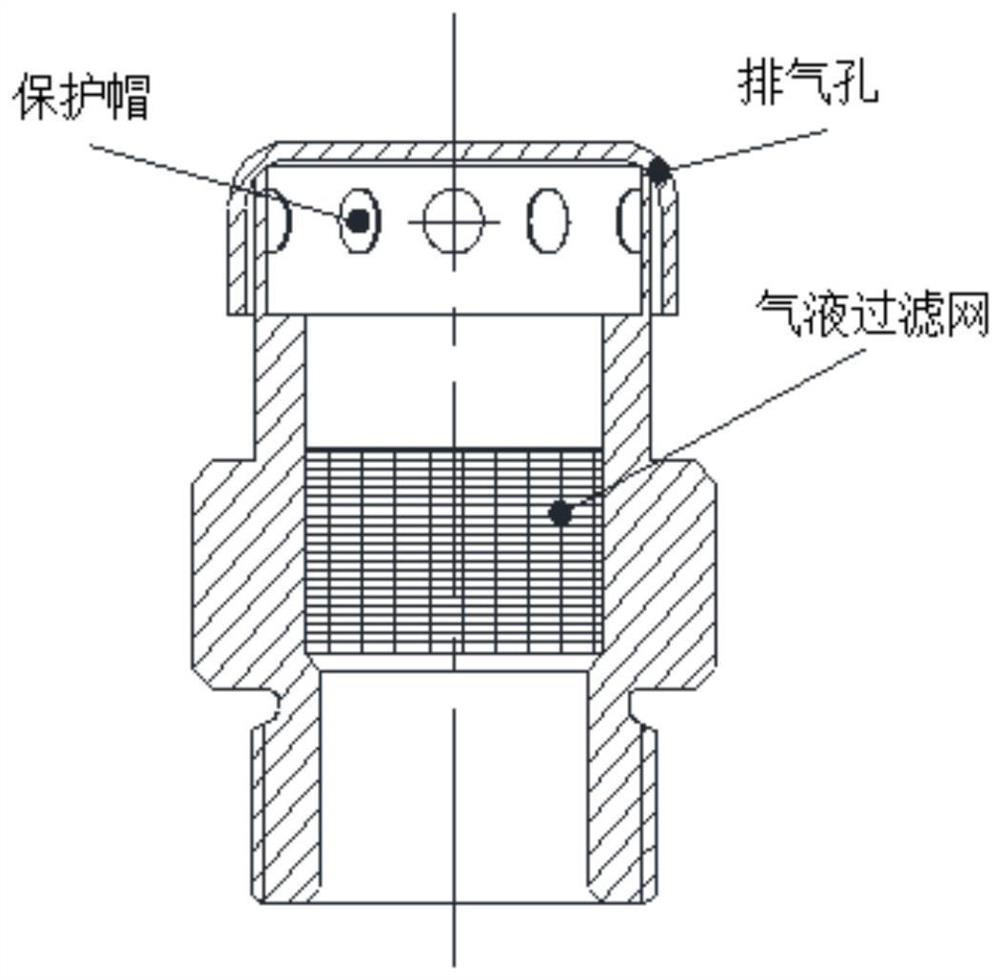

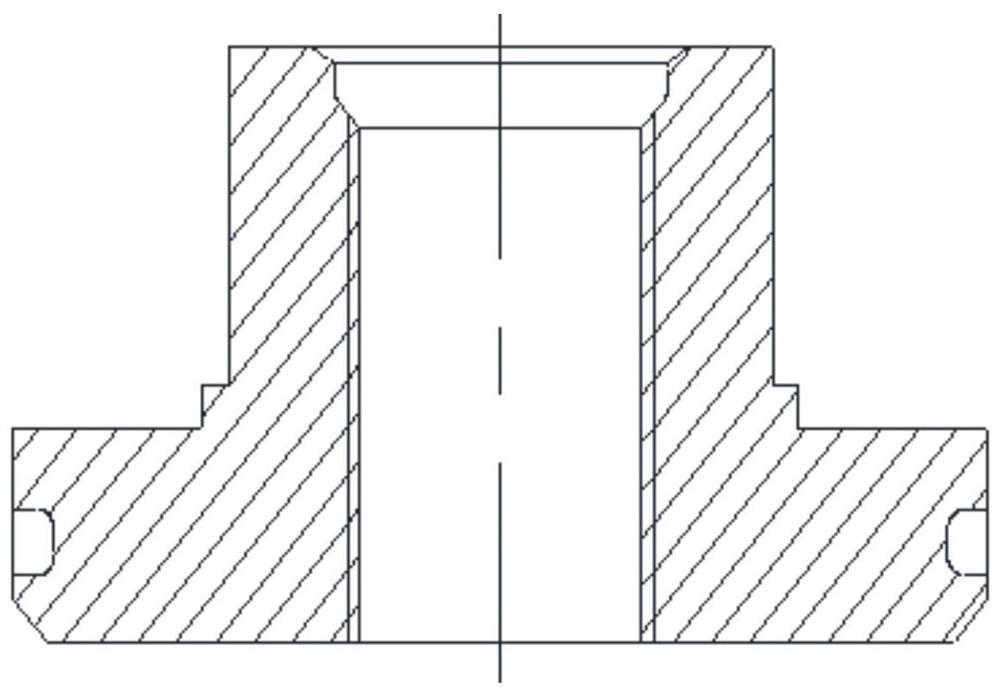

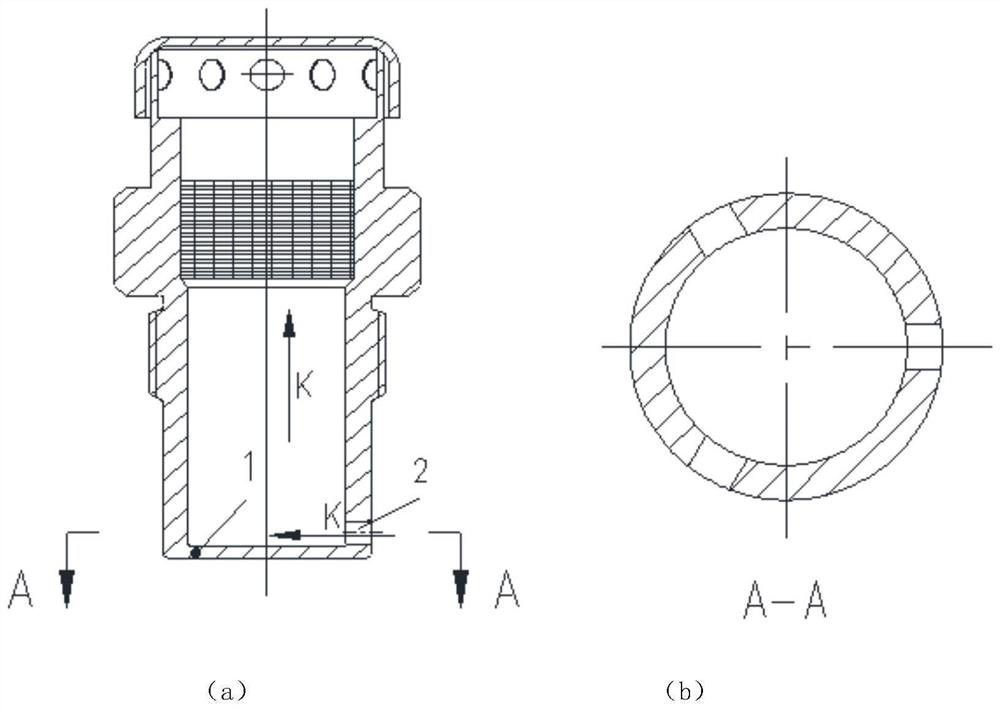

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] The present invention is designed with a bottom plate 1 at the bottom of the ventilation device, which effectively prevents the splashed lubricating oil from directly entering the ventilation device; at the same time, a number of small ventilation holes 2 perpendicular to the inner hole are designed on the side wall of the ventilation device, and the area of the small ventilation holes 2 and not less than the ventilation area of the ventilation plug to ensure the ventilation function; the small ventilation holes 2 are designed to be distributed asymmetrically along the circumference of the side wall of the ventilation device. The gas stays and flows down the inner wall under the action of gravity, and the gas changes direction and flows to the ventilation device, which plays a role in the preliminary separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com