Injector and vehicle

A technology of injectors and injection pipes, applied in fuel injection devices, machines/engines, internal combustion piston engines, etc., can solve the problem that methanol fuel cannot be fully injected, and achieve the effect of shortening the injection distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

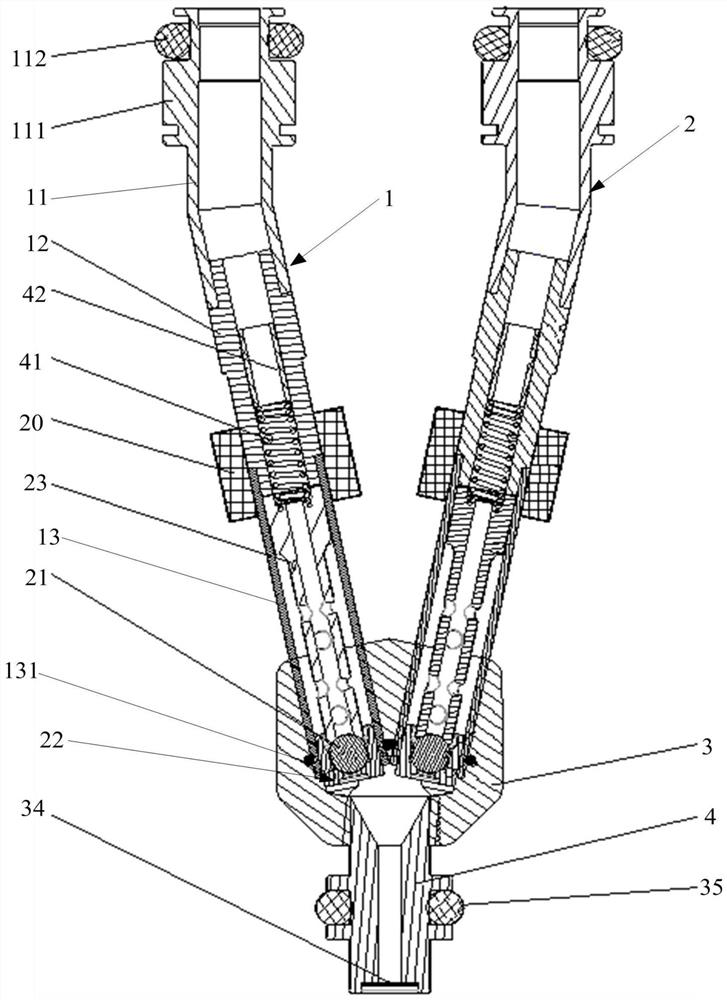

[0029] combine figure 1 As shown, the injector provided by this embodiment 1 includes: a base 3, the base 3 is provided with a first mounting hole and a second mounting hole; a nozzle 4, the nozzle 4 is connected to the base 3, and the nozzle 4 is respectively connected to the first mounting hole and the second mounting hole The two installation holes are connected; the first injection pipe 1, the first injection pipe 1 is located in the first installation hole, the outlet of the first injection pipe 1 communicates with the nozzle 4, and the first injection pipe 1 is used to deliver the first fuel to the nozzle 4 The second injection pipe 2, the second injection pipe 2 is located in the second installation hole, the outlet of the second injection pipe 2 communicates with the nozzle 4, and the second injection pipe 2 is used to deliver the second fuel to the nozzle 4. In this embodiment 1, the first fuel is methanol, and the second fuel is gasoline. The nozzle 4 is used to con...

Embodiment 2

[0052] Embodiment 2 provides a vehicle, including the injector in Embodiment 1 and a control module, the control module is connected to the injector, and the control module is used to control the first injection pipe 1 and the second injection pipe 2 of the injector. The control module in Embodiment 2 can be integrated in the vehicle controller, judge the current demand of the vehicle and control the injector according to the user's operation instruction. In Embodiment 2, the injector can be installed on the cylinder head or the intake pipe of the vehicle.

[0053] In the present invention, the first injection pipe 1 and the second injection pipe 2 are assembled on the base 3 at the same time. When the vehicle uses gasoline, the second injection pipe 2 works to deliver the gasoline to the nozzle 4, and the nozzle 4 passes through the orifice plate , and finally enter the combustion chamber; at this time, the first injection pipe 1 is in a closed state because it is not energiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com