High-efficiency pre-extraction and rapid outburst elimination method of multi-source gas in the process of re-mining and excavation of leftover coal in the middle seam

A technology for gas drainage and middle layer extraction, which is applied in the field of multi-source gas efficient pre-drainage and rapid outburst elimination, can solve problems such as unsafe coal leftover in the middle layer, improve gas extraction efficiency, reduce gas extraction cost, and eliminate outburst danger. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

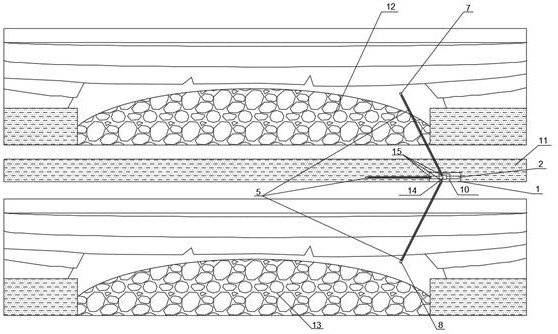

[0028] with H 1 ≥D 1 , H 2 2 (do not consider the influence of the old open space in the upper layer on the roadway of the left coal seam in the middle), and P 2 , P 3 Take the case of ≥0.74MPa as an example to illustrate the implementation steps of drilling:

[0029] 1. At the drilling site (10), construct the upward through-layer drilling (7) to the upper-layer old void (12), and construct the downward through-layer drilling (8) to the lower-layer old void (13); Advance drilling (9) is constructed on the coal body in front of the working face; the boreholes are connected to gas pressure measuring instruments (15) respectively, and the gas pressures in the upper empty area, the left coal seam in the middle, and the lower empty area are measured as P, respectively. 1 , P 2 , P 3 ;

[0030] 2. The main drainage pipe (2) is arranged at the side of the return air lane (1), and the main drainage pipe is suspended on the side of the roadway away from the coal body;

[0031]...

Embodiment 2

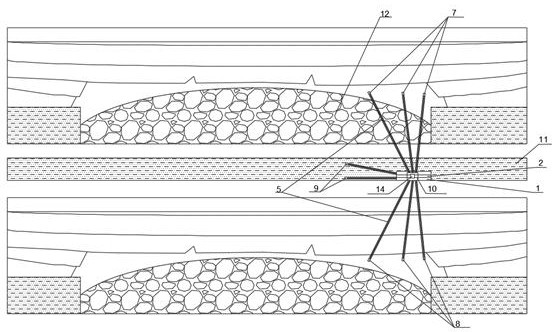

[0036] with H 1 1 , H 2 ≥D 2 , and P 2 ≥0.74MPa>P 1 >P 3 Take this situation as an example to illustrate the implementation steps of drilling:

[0037] 1. At the drilling site (10), construct the upward through-layer drilling (7) to the upper-layer old void (12), and construct the downward through-layer drilling (8) to the lower-layer old void (13); Drilling ahead (9) is carried out on the coal body in front of the working face; the boreholes are respectively connected with gas pressure measuring instruments (15), and the gas pressures of the upper vacant area, the left coal seam in the middle and the lower vacant area are respectively measured as P 1 , P 2 , P 3 ;

[0038] 2. The main drainage pipe (2) is arranged at the side of the return air lane (1), and the main drainage pipe is suspended on the side of the roadway away from the coal body;

[0039] 3. In the return air lane (1), the excavation work faces the front coal body to construct advanced drilling holes (9...

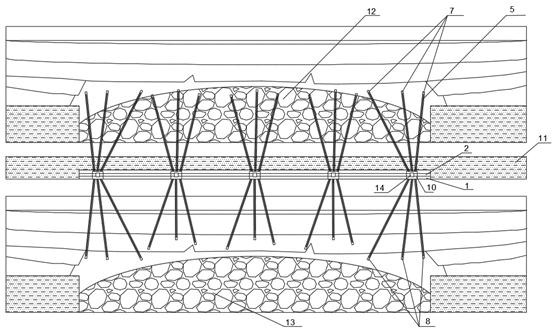

Embodiment 3

[0046] with H 1 1 , H 2 ≥D 2 (do not consider the influence of the old open space in the lower layer on the roadway of the left coal seam in the middle), and P 1 ≥0.74MPa>P 2 Take this situation as an example to illustrate the implementation steps of drilling:

[0047] 1. At the drilling site (10), construct the upward through-layer drilling (7) to the upper-layer old void (12), and construct the downward through-layer drilling (8) to the lower-layer old void (13); Advance drilling (9) is constructed on the front coal mass of the working face; the boreholes are respectively connected to gas pressure measuring instruments (15), and the gas pressures of the upper vacant area, the left coal seam in the middle, and the lower vacant area are measured as P, respectively. 1 , P 2 , P 3 .

[0048] 2. The main drainage pipe (2) is arranged at the side of the return air lane (1), and the main drainage pipe is suspended on the side of the roadway away from the coal body;

[0049] 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com