Tea leaf fermentation equipment and method capable of improving fermentation capability and used for assisting household flower watering

A technology of tea fermentation and fermentation capacity, applied in the preparation and application of organic fertilizers, organic fertilizers, etc., can solve problems such as plant death, and achieve the effect of promoting the fermentation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

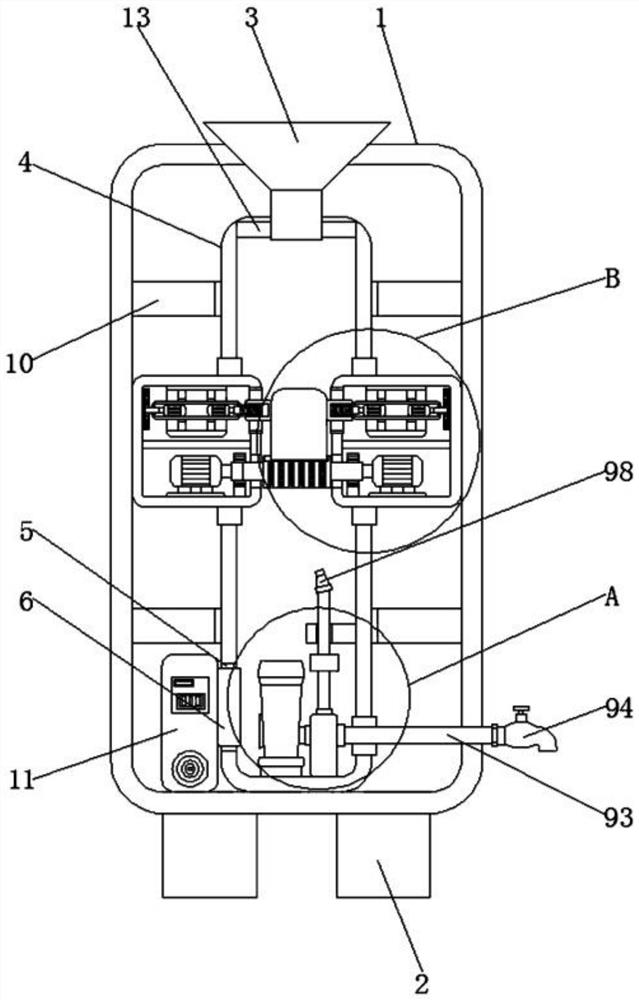

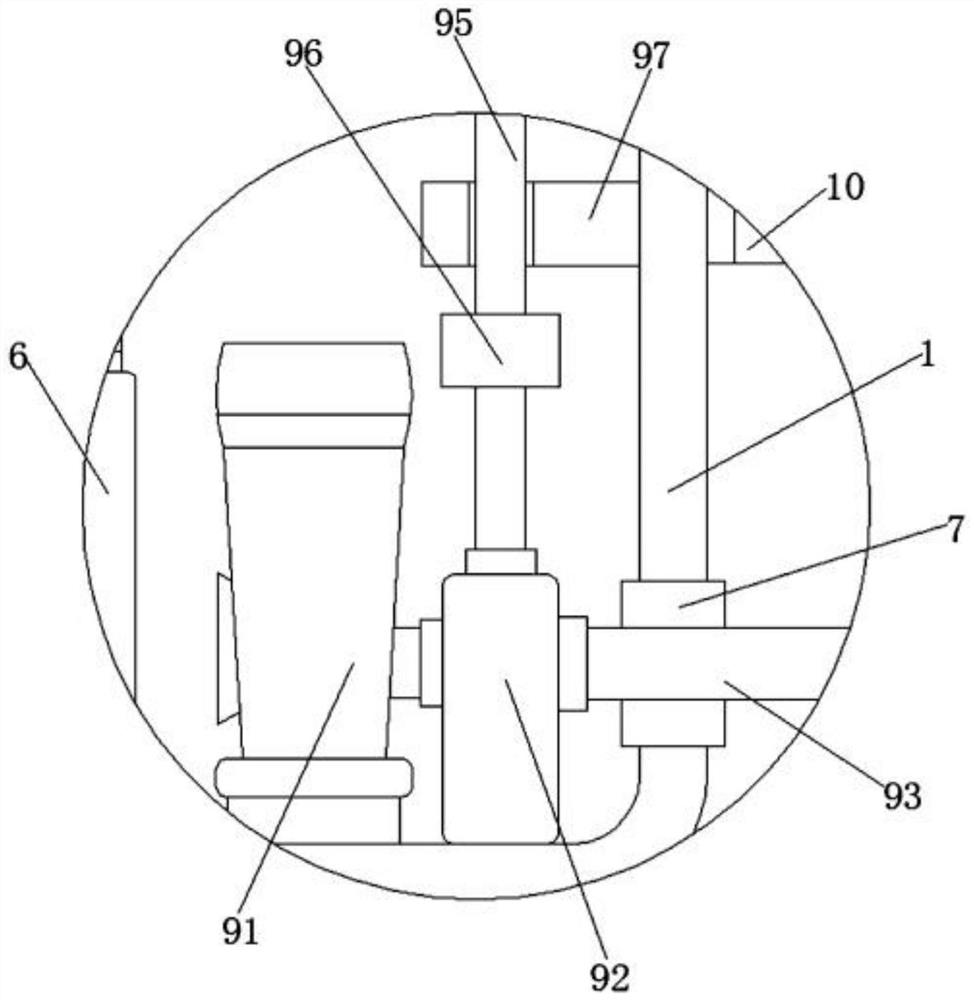

Embodiment 1

[0036] Such as Figure 1-6 As shown in the figure, a tea fermentation equipment for household flower watering assistance that can improve the fermentation capacity includes a vertical tank 1, the two sides of the bottom of the vertical tank 1 are symmetrically fixedly connected with support legs 2, and the center of the top of the vertical tank 1 is fixedly connected with a receiving material The bottom of the pipe 3 and the receiving pipe 3 is fixedly connected with a second sealing gasket 13, and the middle of the bottom of the inner wall of the vertical tank 1 is fixedly connected with a storage box 4, and the bottom of one side of the storage box 4 is provided with a first opening. A first sealing gasket 5 is fixedly connected at the center of the first sealing gasket 5, and the middle part of the first sealing gasket 5 is fixedly connected with a heat conduction plate 6. The bottom of the other side of the storage box 4 is provided with a second opening, and the second ope...

Embodiment 2

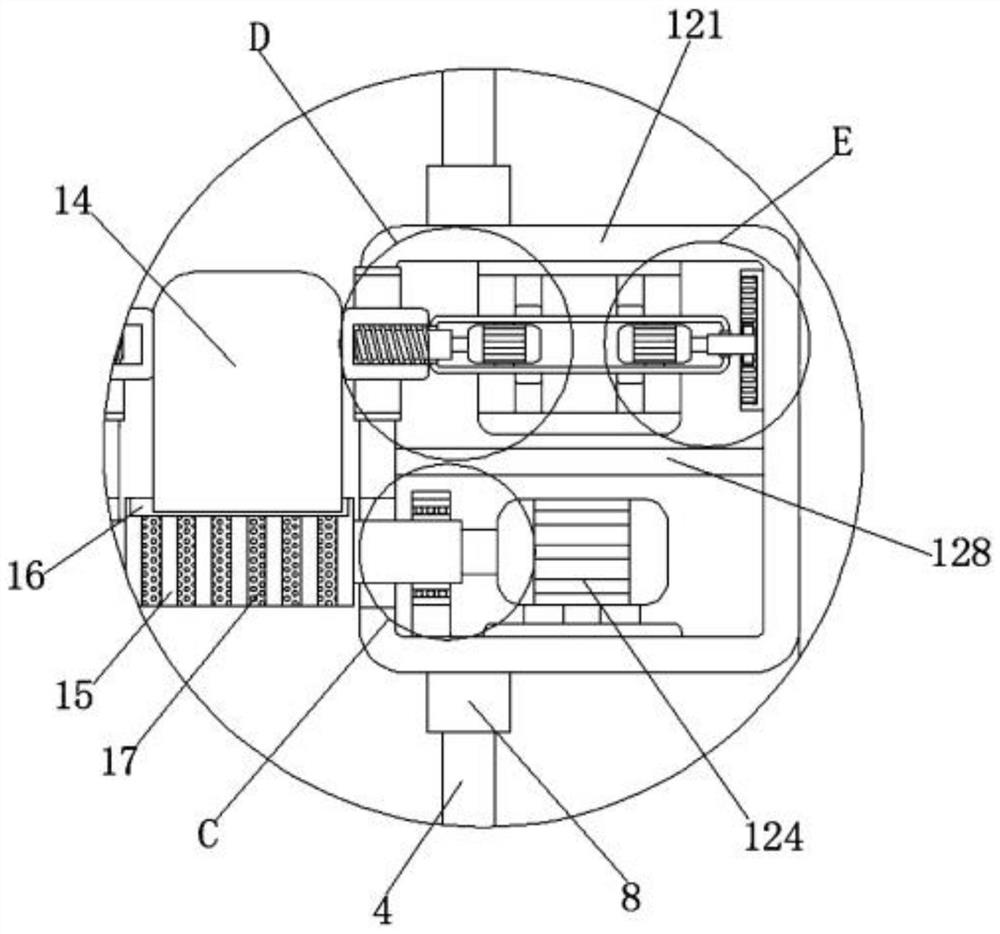

[0038] On the basis of Embodiment 1, the driving mechanism 12 includes a sealed box 121, and the top of the opposite side of the two sealed boxes 121 is symmetrically opened with a fourth opening, and the fourth opening is fixedly connected with a strip groove pad 122, and the two sealed boxes 121 A fifth opening is symmetrically opened on the bottom of the opposite side, and a third sealing gasket 123 is fixedly connected to the fifth opening, and a first motor 124 is fixedly connected to the middle of the bottom of the inner wall of the sealing box 121, and the first motor 124 is close to the third sealing gasket 123 One side of the first motor 124 is extended with an output shaft, the end of the output shaft of the first motor 124 is fixedly connected with a rotating shaft 125, the middle part of the rotating shaft 125 is fixedly connected with a bearing 126, and the outer ring of the bearing 126 is fixedly connected with a support plate 127.

Embodiment 3

[0040] On the basis of Embodiments 1 and 2, the middle part of the inner cavity of the sealed box 121 is fixedly connected with a sealing plate 128, and the middle of the top of the inner wall of the sealed box 121 is fixedly connected with a support sleeve 129, and the front and back sides of the inner wall of the support sleeve 129 are symmetrically opened. There is a chute 1210, and the middle part of the inner cavity of the support sleeve 129 is provided with a load-bearing column 1211. Both sides of the top and bottom of the load-bearing column 1211 are symmetrically fixedly connected with sliders 1212, and both sides of the inner cavity of the load-bearing column 1211 are symmetrically fixedly connected with a second motor. 1213 , a sixth opening is symmetrically opened in the middle of both sides of the load-bearing column 1211 , and a third fixing washer 1214 is fixedly connected to the sixth opening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com