Walking reversing mechanism of four-way vehicle

A reversing mechanism and four-way vehicle technology, applied in the field of warehousing and logistics, can solve the problems of increasing the cost of shuttle vehicles, and achieve the effects of good versatility, high efficiency, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

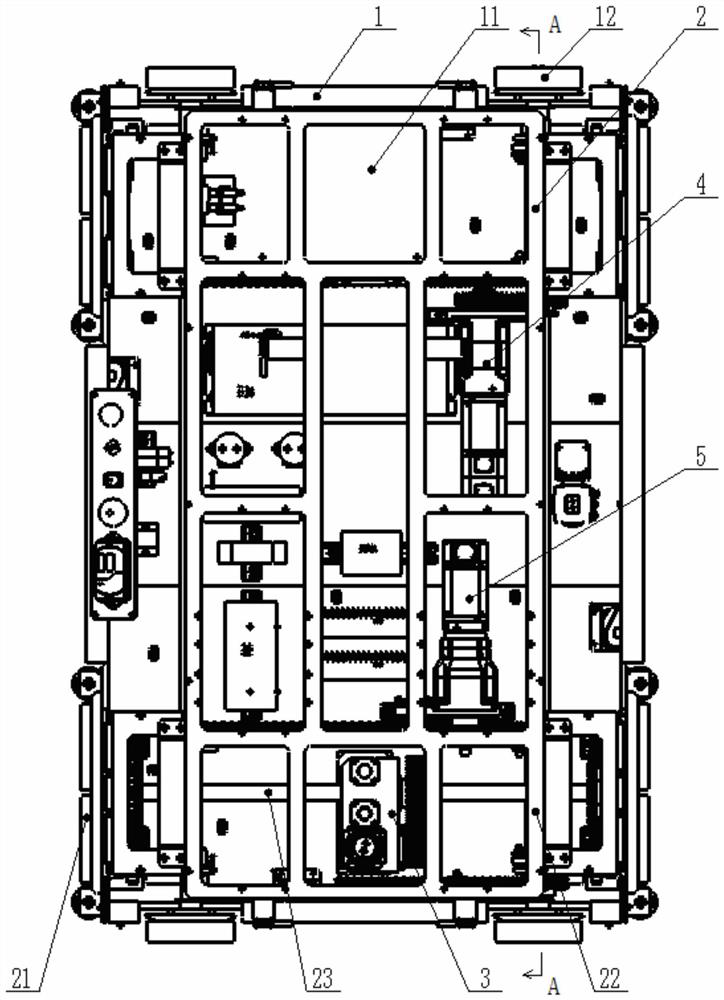

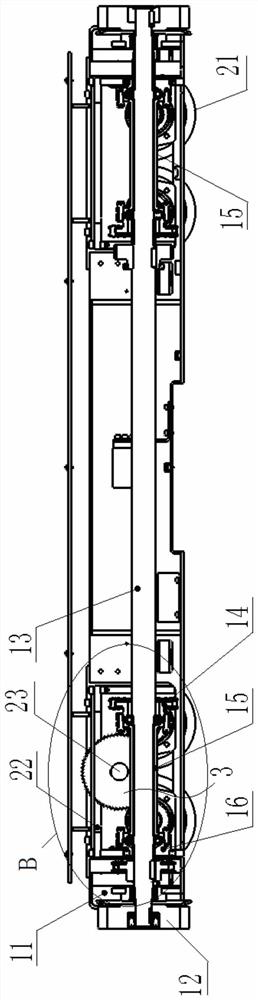

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] Such as Figure 1~5 As shown, the four-way traveling shuttle car includes a transverse traveling system 1 and a longitudinal traveling system 2, wherein the transverse traveling system 1 includes a housing 11, a transverse traveling shaft 13 and a transverse traveling wheel 12, and the two transverse traveling shafts 13 pass through the housing 11 and each transverse travel shaft 13 is provided with lateral travel wheels 12 at both ends, the longitudinal travel system 2 includes a frame 22, a longitudinal travel shaft 23 and a longitudinal travel wheel 21, and the frame 22 is mounted on the casing 11 in a liftable manner Above, two longitudinal travel shafts 23 pass through the housing 11, and the two ends of the longitudinal travel shafts 23 are installed on the frame 22 and rise and fall with the frame 22, and each longitudinal travel shaft 23 ends a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com