Waste film recovery method

A technology of film recovery and material recovery, applied in the field of lithium battery diaphragm production, can solve problems such as waste of raw materials and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

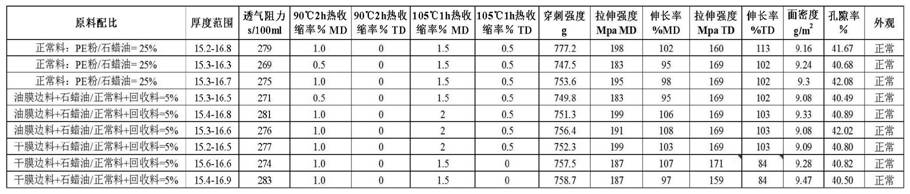

Examples

Embodiment 1

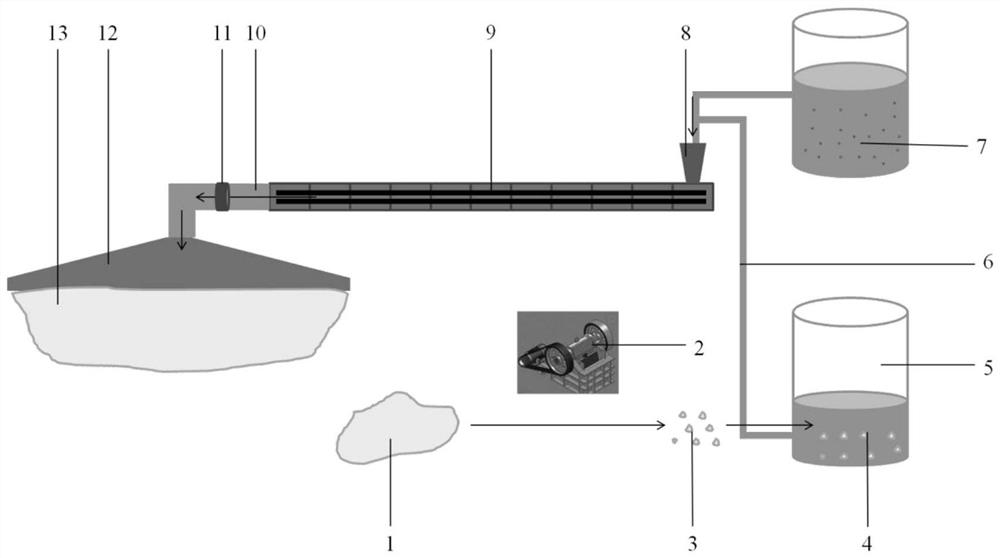

[0039] Collect the oil film scraps and pass the crusher to break the oil film scraps into small fragments with an area not larger than 1cm2, take a few small fragments for oil content test and measure the oil content as 60%;

[0040] The normal material batching tank of the production line includes 1t of PE powder and paraffin oil, of which paraffin oil accounts for 80% of the total mass;

[0041] 500kg of oil film fragments are transferred to the batching tank, and 500kg of paraffin oil is added to make recycled materials, so that the ratio of paraffin oil to the total mass of recycled materials is also 80%;

[0042] Heat the recycled material and the normal material at 120°C and stir for more than 2 hours;

[0043] Set the supply rate of recycled material and normal material to 10kg / h and 290kg / h respectively, pump them into the feeding hopper, plasticize in the twin-screw extruder, filter out impurities through the filter, and then pass through the mold Extrude through the...

Embodiment 2

[0045] Collect the dry film scraps and break the oil film scraps into small fragments with an area not larger than 1cm2 through a crusher, take a few small fragments for oil content test and measure the oil content as 0.2%;

[0046] The normal material batching tank of the production line includes 1t of PE powder and paraffin oil, of which paraffin oil accounts for 70% of the total mass;

[0047] 200kg of dry film fragments are transferred to the batching tank, and 465.3kg of paraffin oil is added to make recycled materials, so that the ratio of paraffin oil to the total mass of recycled materials is also 70%;

[0048] Heat the recycled material and the normal material at 120°C and stir for more than 2 hours;

[0049] Set the supply rate of recycled materials and normal materials to 15kg / h, 285kg / h, pump them into the feeding hopper, plasticize in the twin-screw extruder, filter out impurities through the filter, and then pass through the die Extrusion is carried out to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com