Internal air flow self-circulation type impact crusher

An impact crusher and self-circulation technology, which is applied in grain processing and other directions, can solve the problems of limited improvement of exhaust pressure and exhaust volume, increase of return air resistance, and extension of return air passage, so as to reduce air pressure and increase Effect of return air resistance and reduction of exhaust air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

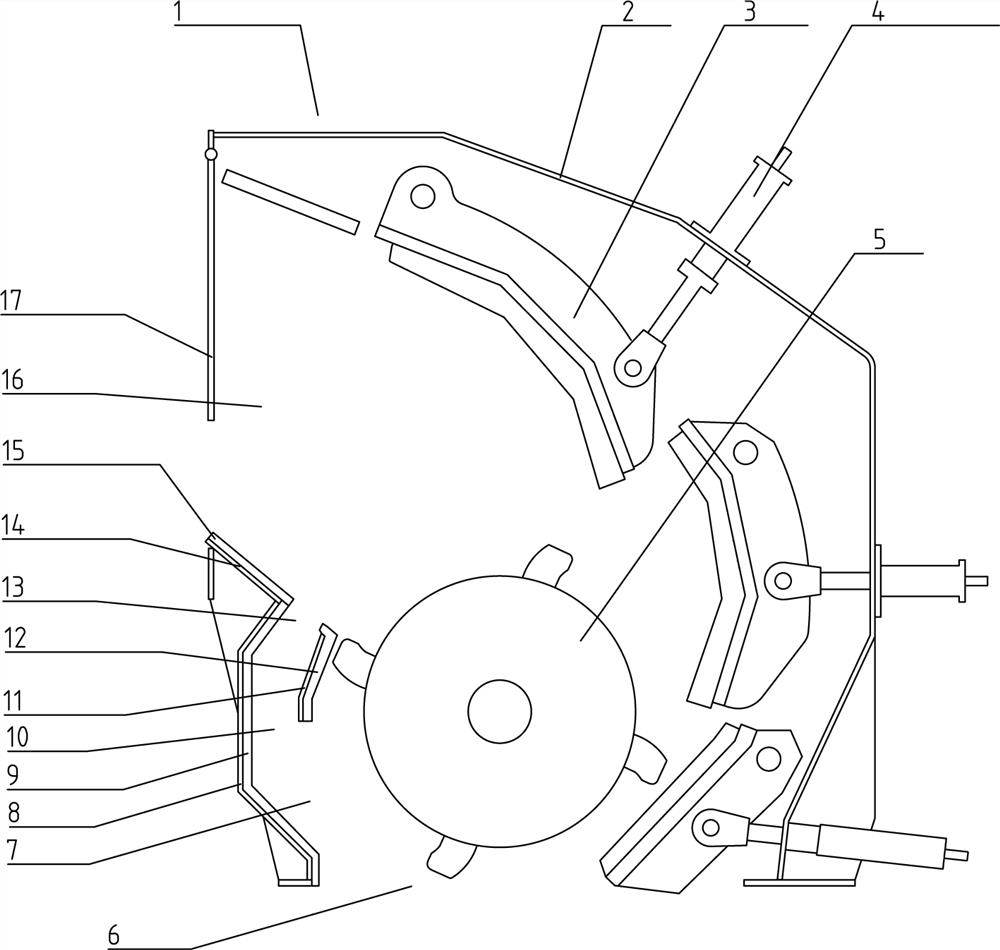

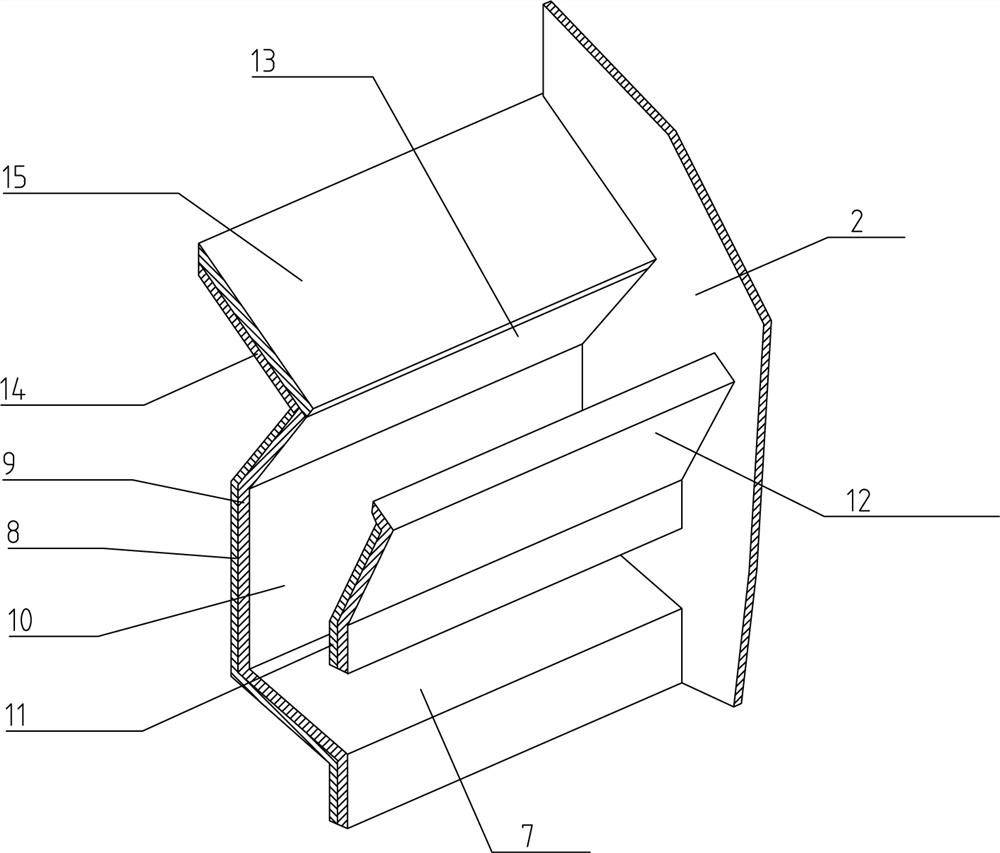

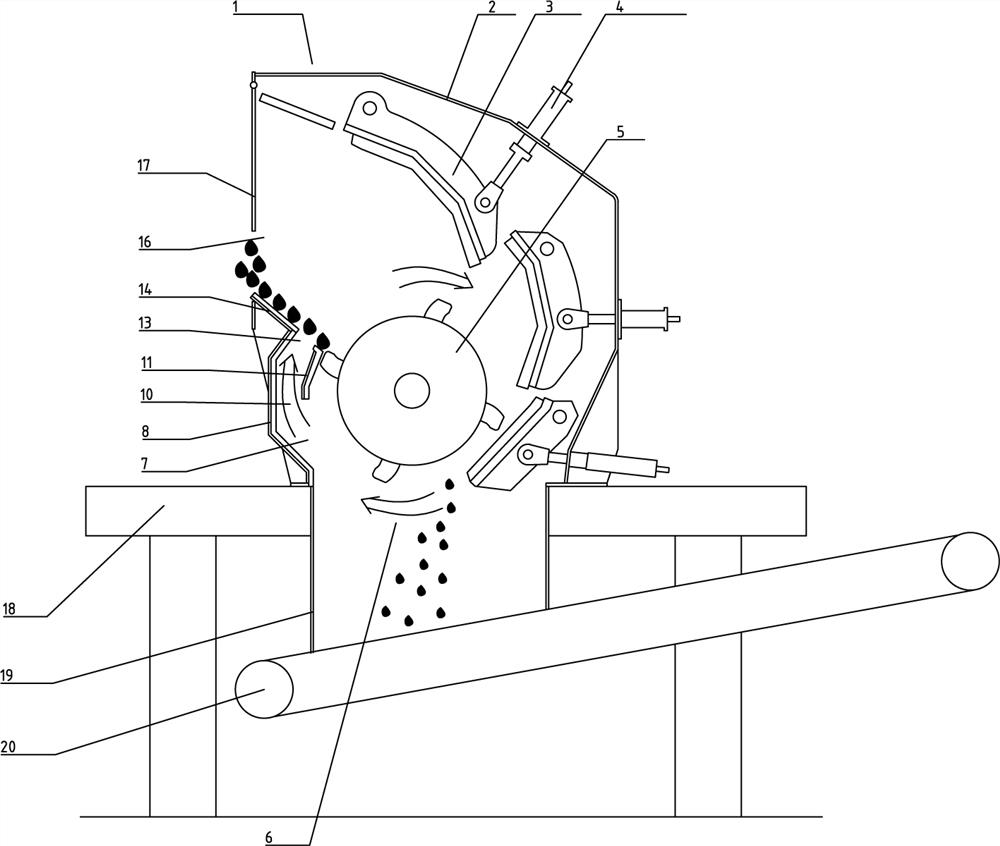

[0025] Such as Figure 1 to 3 As shown, an internal gas stream is self-circulating a refractor, including a counteractor 1 mounted on the base 18, and the anti-crusher 1 includes a rack 2, the top of the frame 2 through the counterattack adjustment device 4 Connecting a counterattack 3, the counterattack adjustment device 4 penetrates the top of the frame 2, the counterattack 3 is hinged to the corresponding counterattack adjustment device 4, and the lower portion of the frame 1 is mounted with a rotor 5, and the rotor 5 remains below the bottom. The mouth 6 is connected to the discharge port 6, and the sealing cover 19 is provided with a conveyor belt 20, and the sealing cover 19 is closed and the conveyor belt 20 is closed; the rack is connected to the inlet The mouth-proof curtain 17, and the feeder slide 14 is fixed under the frame, and the injection slide 14 is inclined downward, and the feed mouth slip plate liner 15 is fixed. The injection skillet liner 15 is made of an abra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com