Jet noise active control test platform based on engine nozzle scale model

A technology of engine nozzles and scaled models, which is applied in jet engine testing, gas turbine engine testing, etc., can solve the problems of lack of test platform for active jet flow noise control of aeroengines, limited by the site, high test funds, etc., to achieve test The effect of short preparation time, strong anti-risk ability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

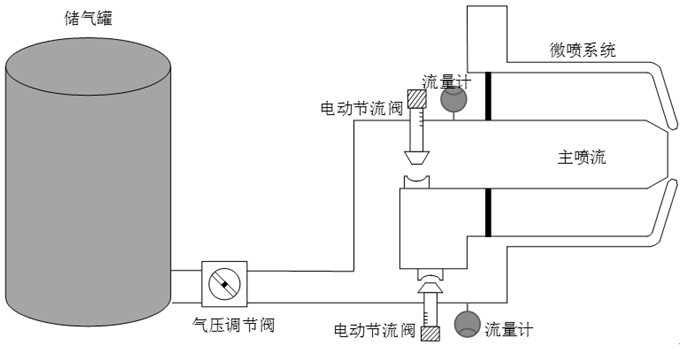

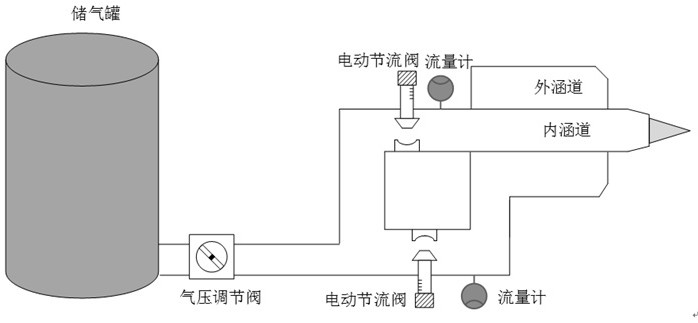

[0025] The schematic diagram of the jet noise active control test platform based on the turbofan engine nozzle scale model is as follows: figure 1 shown. It consists of a turbofan engine nozzle scale model, air supply system, noise reduction test chamber, noise spectrum measurement device, electric valve and controller. The air supply system adopts a screw air compressor and a high-pressure air tank. By adjusting the opening of the electric valve, the air flow and the micro-jet flow entering the inner and outer ducts are changed. The control signal of the electric valve is given by the controller, which provides a serial Line interface and external data transmission. The size of the jet noise radiation is controlled by the micro-jet flow rate and the configuration and angle of the guide vanes in the outer duct. For the nozzle test piece of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com