A kind of production technology of silicon carbide titanium

A production process, silicon carbide titanium technology, applied in the chemical industry, carbon compounds, inorganic chemistry, etc., can solve the problems of easy formation of heterogeneous phases, complex production process, high temperature and high sintering requirements, low temperature requirements and good product purity , The effect of easy access to raw materials

Active Publication Date: 2022-05-31

辽宁中色新材科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Chemical vapor phase synthesis is the use of SiCl 4 、TiCl 4 , CCl 4 As a raw material in a vapor deposition furnace, Ti is deposited by vapor deposition 3 SiC 2 ; The reaction conditions of the vapor deposition method are relatively harsh, and the product purity is not easy to control and easy to form impurity phases, and the product output is small, which is not conducive to industrial production

The pressing and sintering method is to use the mixed powder of Ti, SiC and graphite to be cold-pressed and then reacted at 1600°C under a pressure of 40 MPa. In this method, SiC is used as a raw material, and silicon carbide has a high hardness. It takes a long time to pulverize the powder to obtain it, and The loss is large; and the chemical stability of silicon carbide is high, the sintering requires high temperature, and SiC impurity phases are easy to exist in the product, the whole production process is complicated and the cost is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Login to View More

Abstract

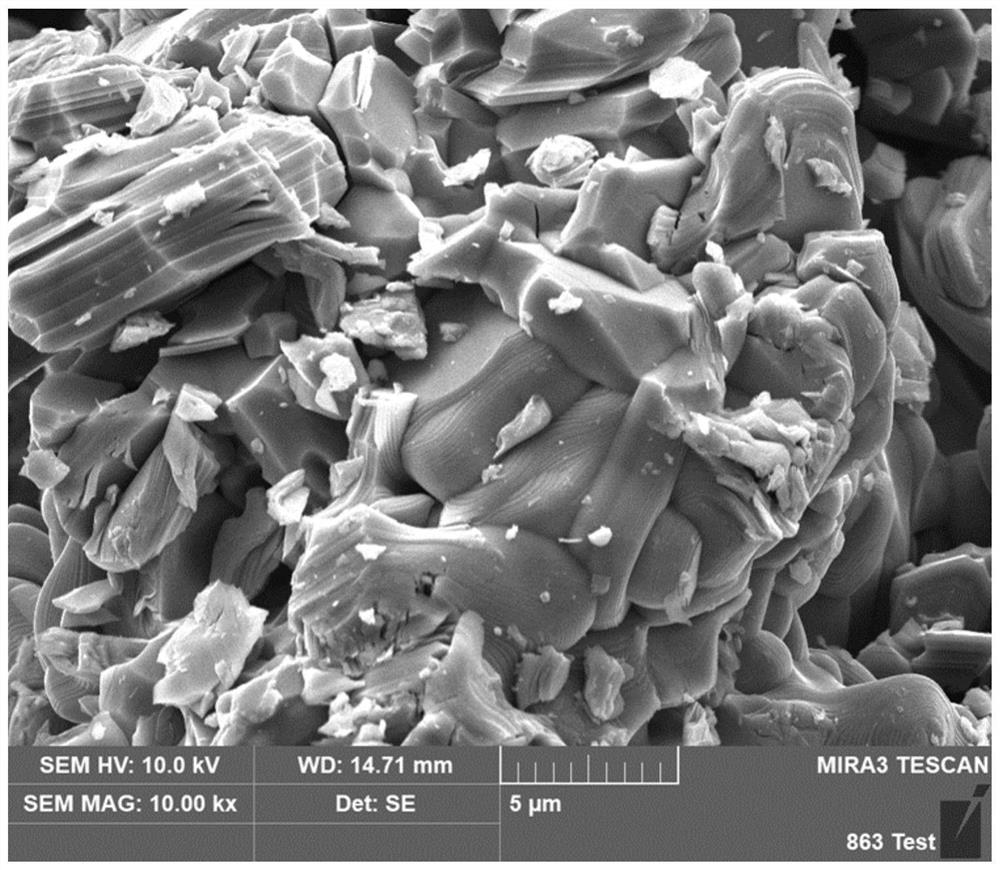

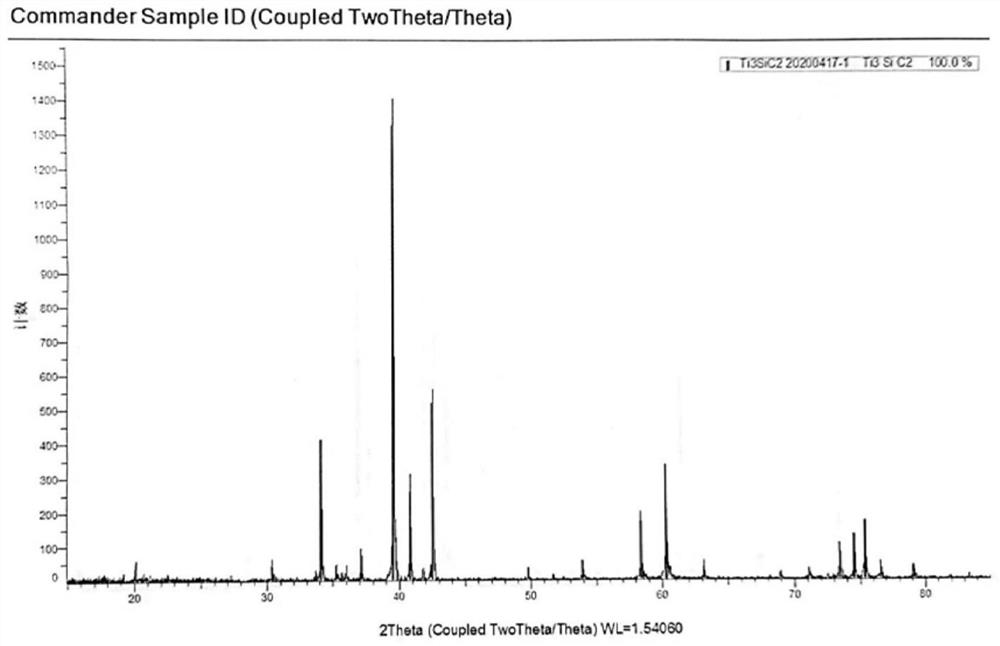

A production process of silicon carbide titanium, the sponge titanium and single crystal silicon are loaded into a vacuum induction melting furnace, and the temperature is continuously raised until the sponge titanium and single crystal silicon are remelted, then the vacuum is stopped; after filling with argon, stirring and pouring Fix the mold to obtain titanium-silicon alloy ingot; process the titanium-silicon alloy ingot into titanium-silicon alloy powder; put titanium-silicon alloy powder and graphite powder into a vacuum ball mill, add binder, and ball mill and mix the materials for 24 hours under the protection of argon , use a press to press into a round cake, put it into the crucible of a vacuum resistance furnace, evacuate, heat up to 1100°C, vacuum to 25Pa, keep warm for 3.5 hours, continue to heat up to 1350°C, vacuum to 25-350Pa, keep warm, After full alloying, fill with argon, continue to heat up to 1520 ° C for 3 hours, and obtain Ti 3 SiC 2 blocks. The raw material is primary, the cost is low, no further processing is required, the temperature requirement in the whole reaction process is not high, the product purity is good, and large-scale industrial production is possible.

Description

A kind of production process of silicon carbide titanium technical field [0001] The invention belongs to the field of ceramic material preparation, in particular to a production process of silicon carbide titanium. Background technique Silicon carbide titanium is a new type of ternary layered ceramic material, which has both the composite properties of metal and ceramics. The mechanical properties of metal, with good electrical conductivity, thermal conductivity and high temperature plasticity, it can use high-speed steel tools like metal Mechanical processing; it also has the high melting point, thermal shock resistance and oxidation resistance of ceramic materials, and its thermal stability can reach 1300 ℃, it has a lower coefficient of friction and better self-lubricating properties than graphite. Silicon carbide titanium is widely used in electromechanical engineering Contact parts, heat sinks for electronic packaging in the electronics industry, and continuous...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01B32/90C22C1/02C22C14/00

CPCC01B32/90C22C1/02C22C14/00C01P2002/72C01P2004/03Y02P20/10

Inventor 张洪涛

Owner 辽宁中色新材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com