Crushing and screening equipment used for biomass energy particles and based on centrifugal force principle

A technology of biomass energy and screening equipment, which is applied in the fields of filtration, solid separation, grain processing, etc., and can solve the problem of low production quality of production source particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

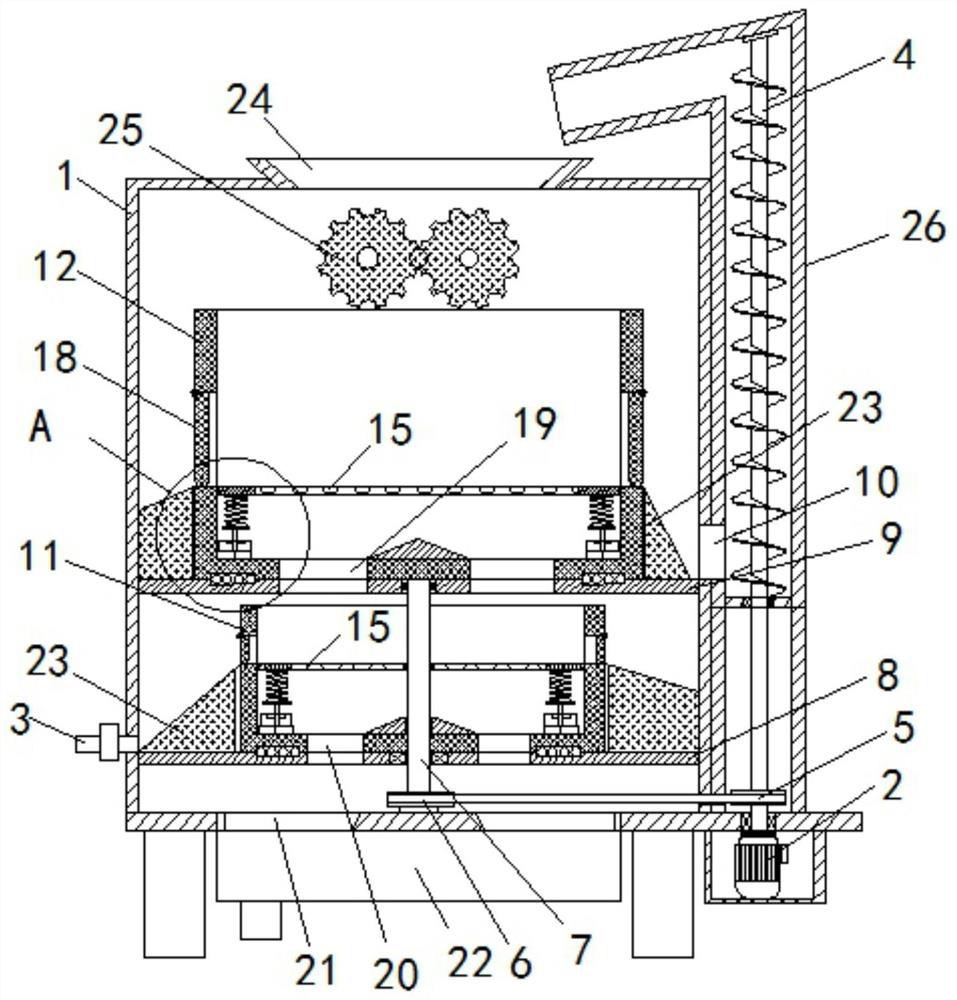

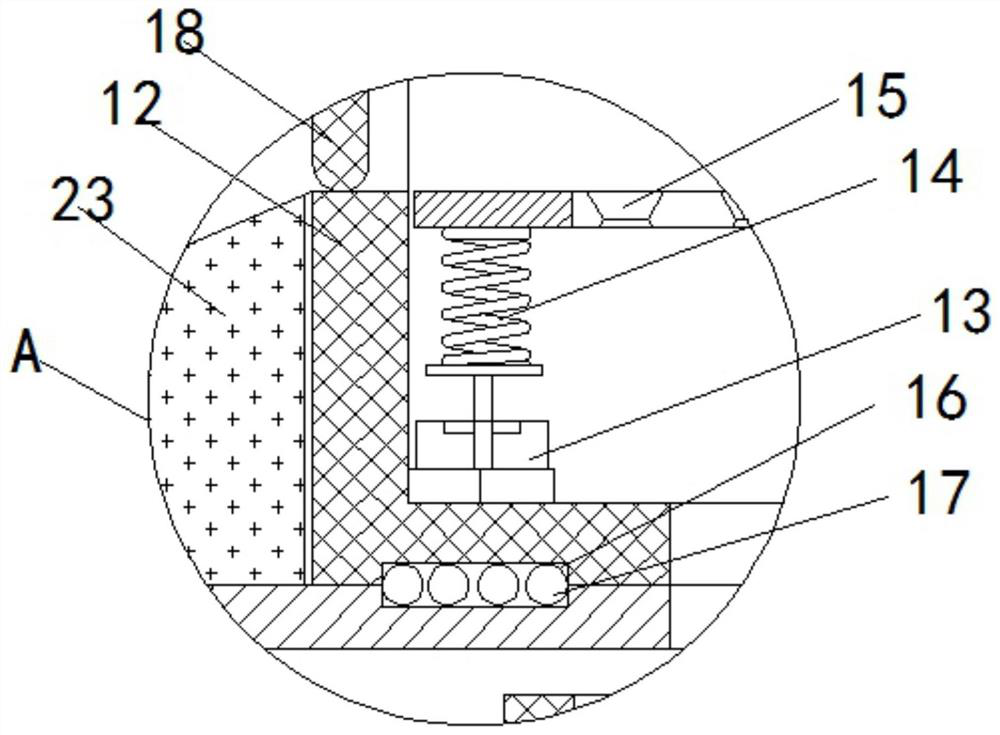

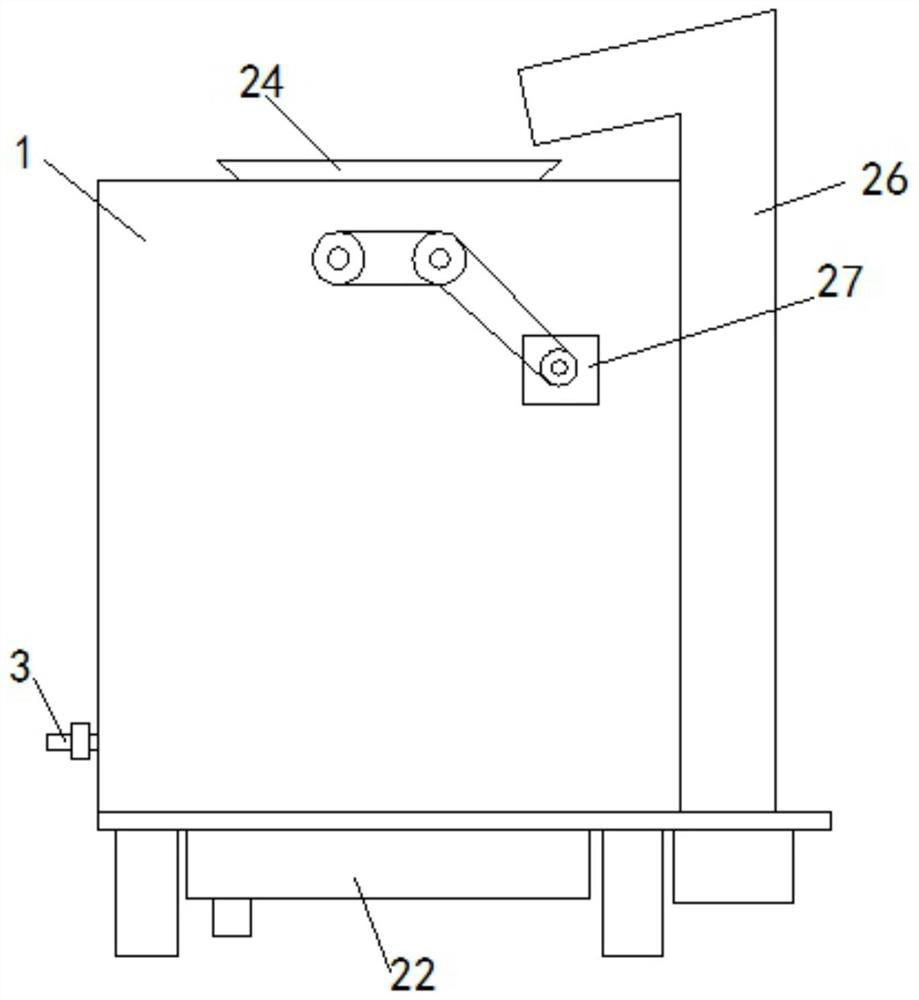

[0028] as attached figure 1 to attach Figure 4 Shown:

[0029] A crushing and screening equipment for biomass energy particles based on the principle of centrifugal force, including a casing 1, a first motor 2 is fixedly installed on the right bottom of the casing 1, the model of the first motor 2 is MSMJ-MCDKT3520, and the first motor 2 The output end is fixedly connected with the feeding rod 4, the outer wall of the feeding rod 4 is sleeved with the driving wheel 5, the driving wheel 5 is connected with the driven wheel 6 through the belt transmission, the driven wheel 6 is sleeved with the rotating shaft 7, and the bottom end of the rotating shaft 7 passes through the bearing It is rotatably connected with the bottom end of the housing 1, and the inside of the housing 1 is fixedly installed with a first partition 8 and a second partition 9, the second partition 9 is located above the first partition 8, and above the first partition 8 is placed a The first screening bucke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com