Synchronous masonry method for strong and weak current box prefabricated members

A weak current box and prefabricated technology, applied in electrical components, buildings, building components, etc., can solve problems such as inability to get rid of, inconvenience, etc., and achieve the effect of speeding up construction progress, reducing project costs, and avoiding hollowing and cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The strong and weak electric box prefabricated synchronous masonry method of the present invention comprises the following steps:

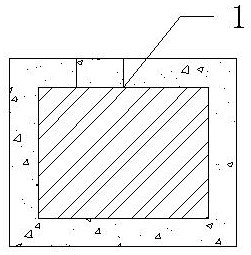

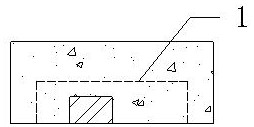

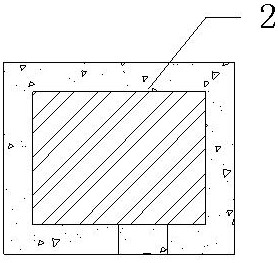

[0026] a. Pouring the periphery of the strong and weak current boxes with reinforced concrete into prefabricated parts of the strong and weak current boxes with the same wall width; figure 1 It is a structural schematic diagram of the prefabricated part of the strong electric box according to the embodiment of the present invention, figure 2 for figure 1 top view. image 3 It is a structural schematic diagram of the weak current box prefabricated part of the embodiment of the present invention, and 4 is image 3 top view.

[0027] b. During masonry, the prefabricated parts of the strong and weak current boxes are directly regarded as blocks for synchronous masonry. The dimensions and specifications of the prefabricated components of the strong and weak current boxes are the same as those of the wall blocks. Figure 5 It is the front v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com