Novel reverse beating process for tapestry brick of exterior wall based on high-performance cement-based material

A cement-based material, high-performance technology, applied in the field of construction, can solve problems such as pointing, difficulty in controlling the quality of tiles, and troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

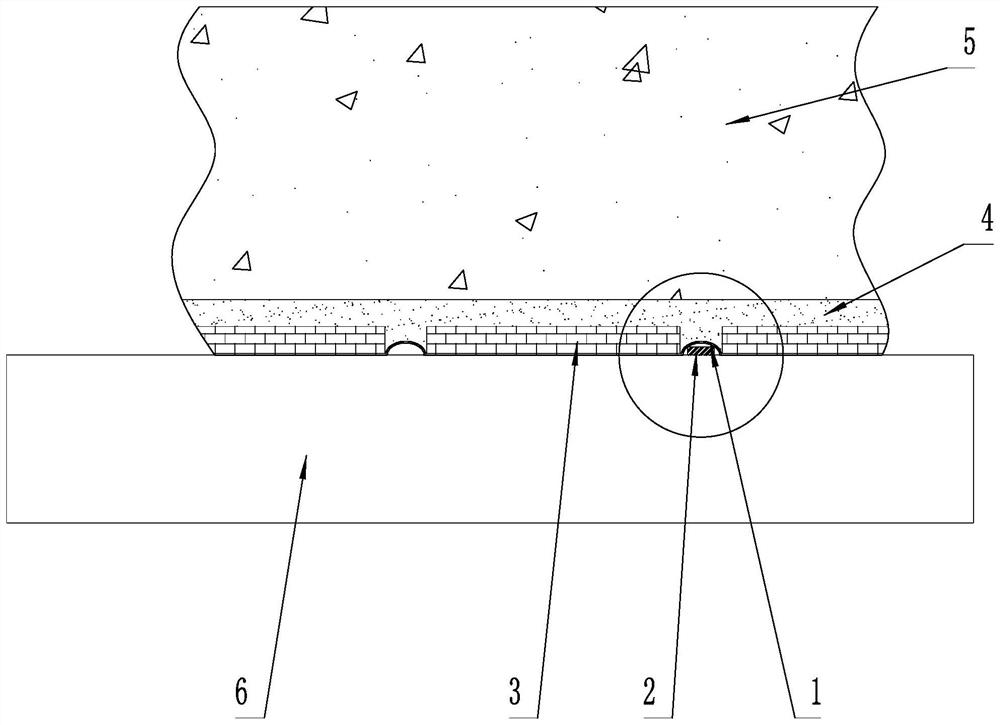

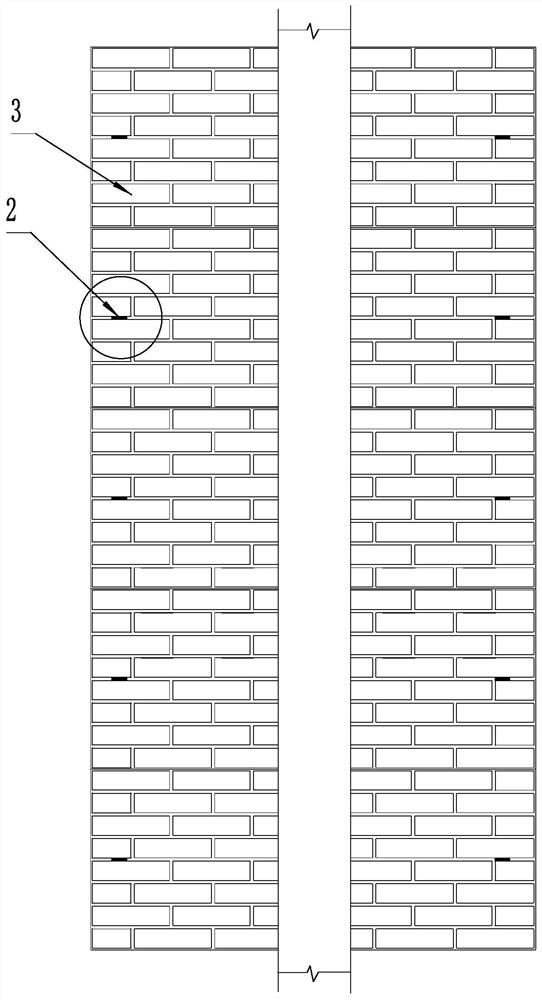

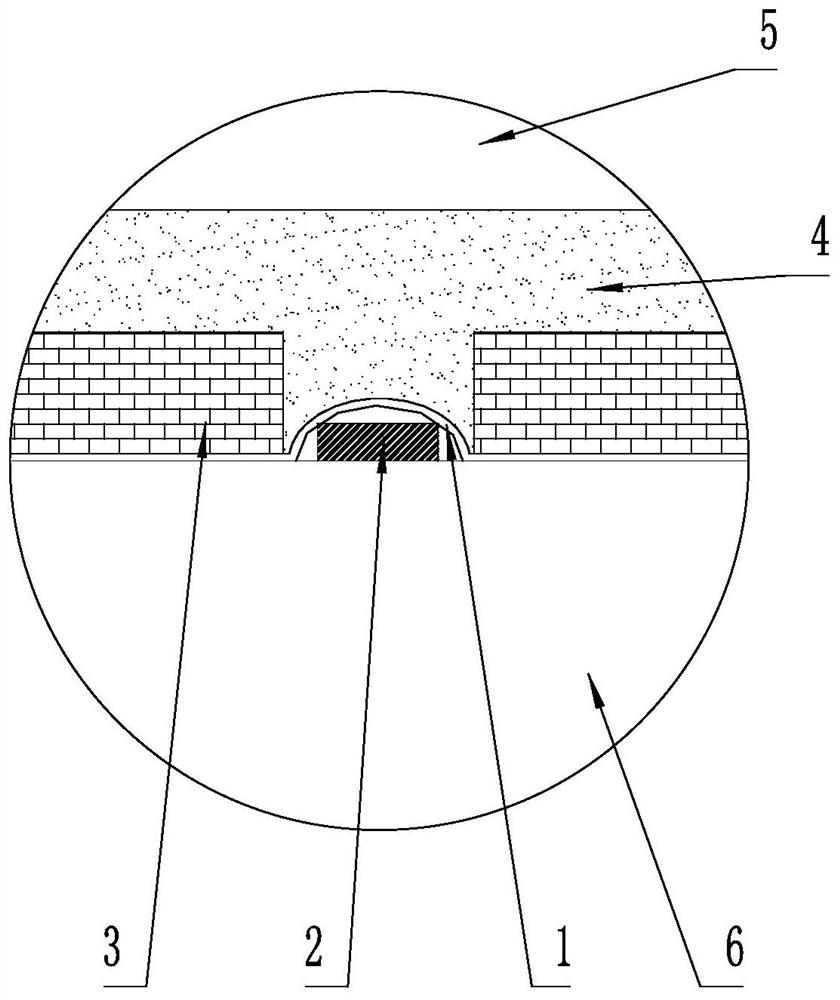

[0030] like figure 1 , figure 2 , image 3 As shown, a new type of back-beating process for exterior wall bricks based on high-performance cement-based materials,

[0031] The construction steps of the new exterior wall brick back-beating process are as follows:

[0032] The first step is to place the PE film positioning block 2 on the mold table 6 according to the drawings;

[0033] In the second step, the PE film 1 is laid on the PE film positioning block 2;

[0034] The third step is to embed the facing brick 3 face down into the film grid of the PE film 1;

[0035] The fourth step is to lay a layer of high-performance cement-based material 4 with a certain thickness on the laid face brick 3 to form a high-performance cement layer, and at the same time, the high-performance cement-based material 4 is embedded in the joint of the face b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com